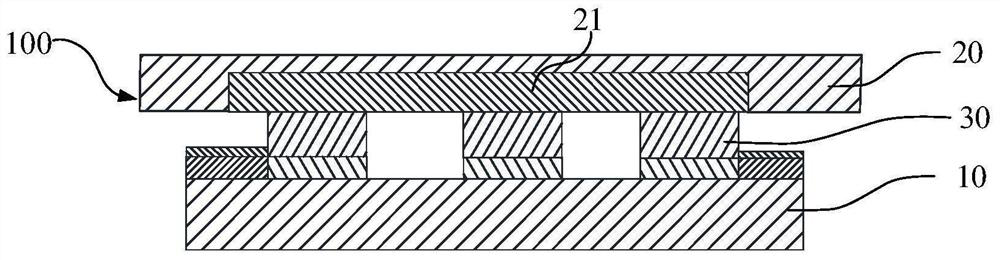

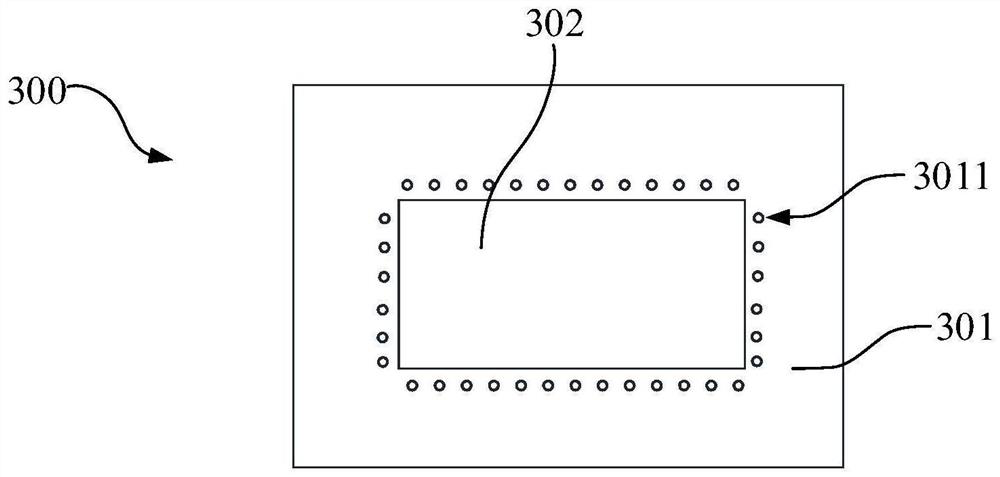

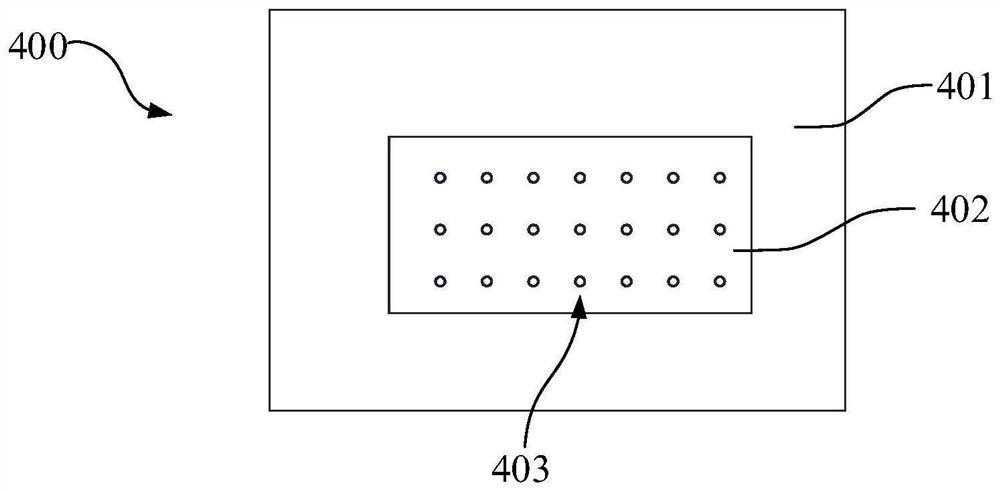

PCB board and components

A technology for PCB boards and components, applied in the field of electronic products, can solve the problems of reduced working efficiency, large heat dissipation, and high power consumption of components, and achieve the effects of improving welding quality and thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Based on the attachment and embodiments, the application is further described in detail. In particular, the following examples are only used to illustrate this application, but the scope of this application is not limited. Similarly, the following examples are only the implementation examples of this application. All other embodiments obtained by ordinary technical personnel in the art under the premise of not creative labor are the scope of this application protection.

[0030] In this article, "Examples" means that the specific features, structures, or characteristics described in combination with the embodiment can be included in at least one embodiment of this application. The emergence of the phrase in each position in the instructions does not necessarily refer to the same examples, nor is it an independent or alternative embodiment that mutually exclusive or alternatively with other embodiments. The technical personnel in the art are explicitly and implicitly underst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com