Stopper rod with crusting preventing heat preservation function

A technology of anti-crust and stopper, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the problems of physical hazards of workers in the workshop environment, failure to prevent the temperature drop of molten steel, and pollution of molten steel, so as to improve the casting slab Quality, improving the environment of the continuous casting workshop, and ensuring the effect of smooth progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

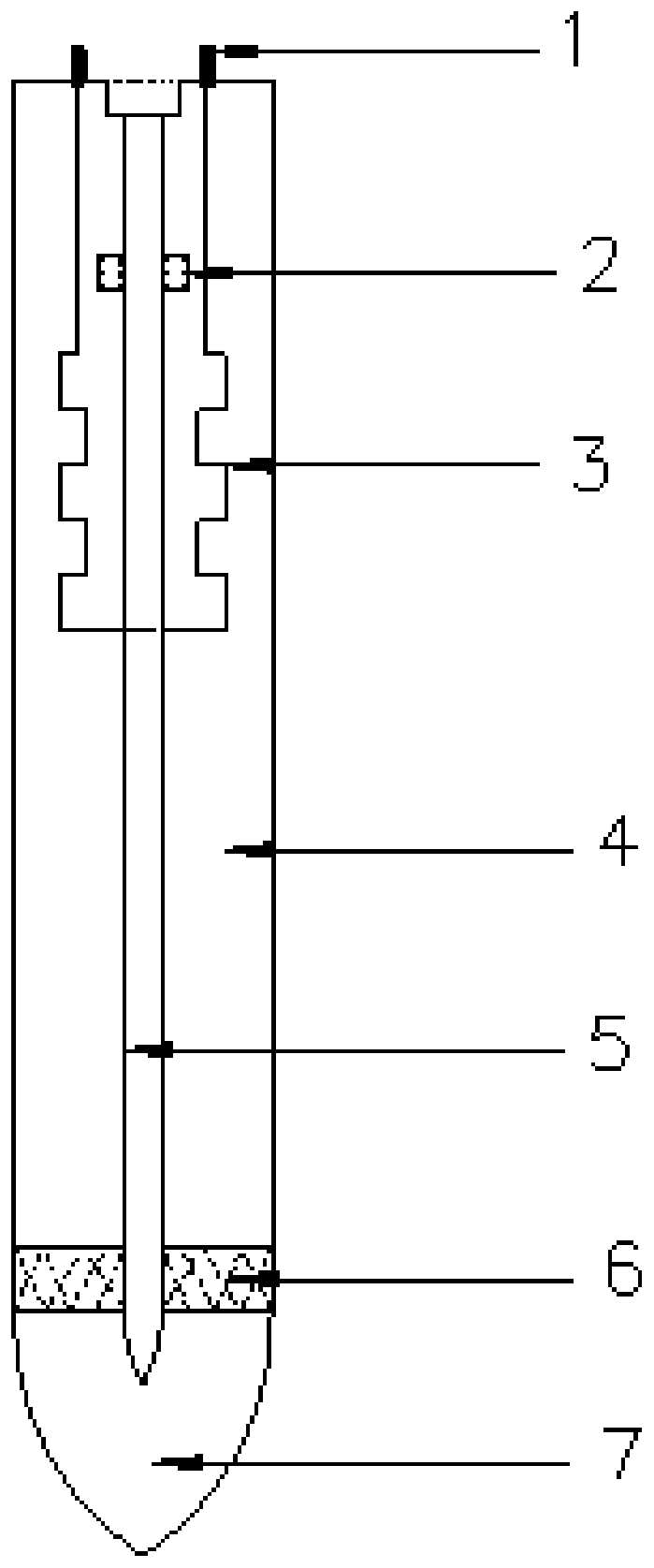

[0024] A stopper rod with anti-crust and heat preservation functions, such as figure 2 As shown, it includes the club tail, the club body 4, the club head 7, and the transition layer 6 between the club body 4 and the club head 7. The interior of the club body 4 is provided with an inner cavity 5, and the inner cavity 5 passes through the transition layer. 6. The main function of the rod head is to cooperate with the nozzle bowl of the tundish to control the flow. In order to maintain a good flow control effect of the rod head during the steel pouring process, its ability to resist molten steel erosion must be strong, and the transition layer is only in the The bar body material and the bar head material play a transitional role, and its ability to resist molten steel erosion is poor. The reason why the transition material is not penetrated to the bar head is because the transition layer and the bar head material are not synchronized in resisting molten steel erosion. In order...

Embodiment 2

[0030] Wind the resistance wire 3 made of nickel-chromium material with a wire diameter of 2.5 mm into 5 rings with a diameter of 50 mm, and put it in the center of the core rod when the stopper rod is formed, and part of the resistance wire 3 exposes the tail of the rod, so that the resistance wire 3 The wire 3 is 25mm away from the outer body of the stopper, and is molded together with the stopper mud in a 125MPa isostatic press. After demoulding the formed stopper rod, connect it to the external power supply through the resistance wire 3 under the voltage of 220V, and at the set heating rate, after 1 hour, the inside of the stopper rod is equipped with the resistance wire 3 part, and passes through the temperature measuring gun The measured temperature is 251°C, which is lower than the set heating rate requirement. After continuing to heat up for 3 hours, the part 3 of the resistance wire on the stopper turns red. At this time, the measured temperature of this part is 1074°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com