Drilling device for preventing thick paper from being scratched after being printed

A drilling device and paper skin technology, applied in metal processing and other directions, can solve the problems of reducing production efficiency, scratching patterns and characters, increasing production processes, etc., and achieving the effect of preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

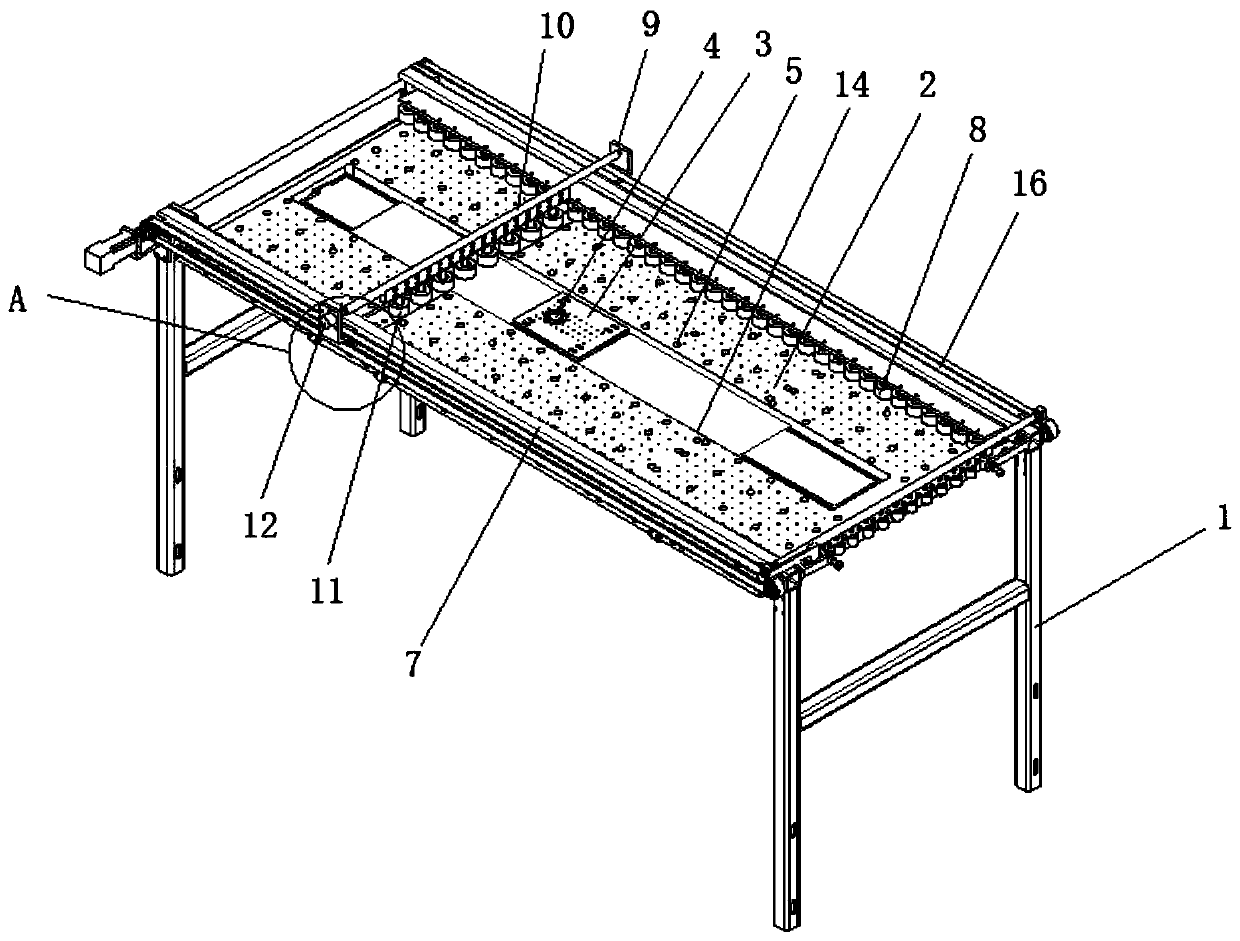

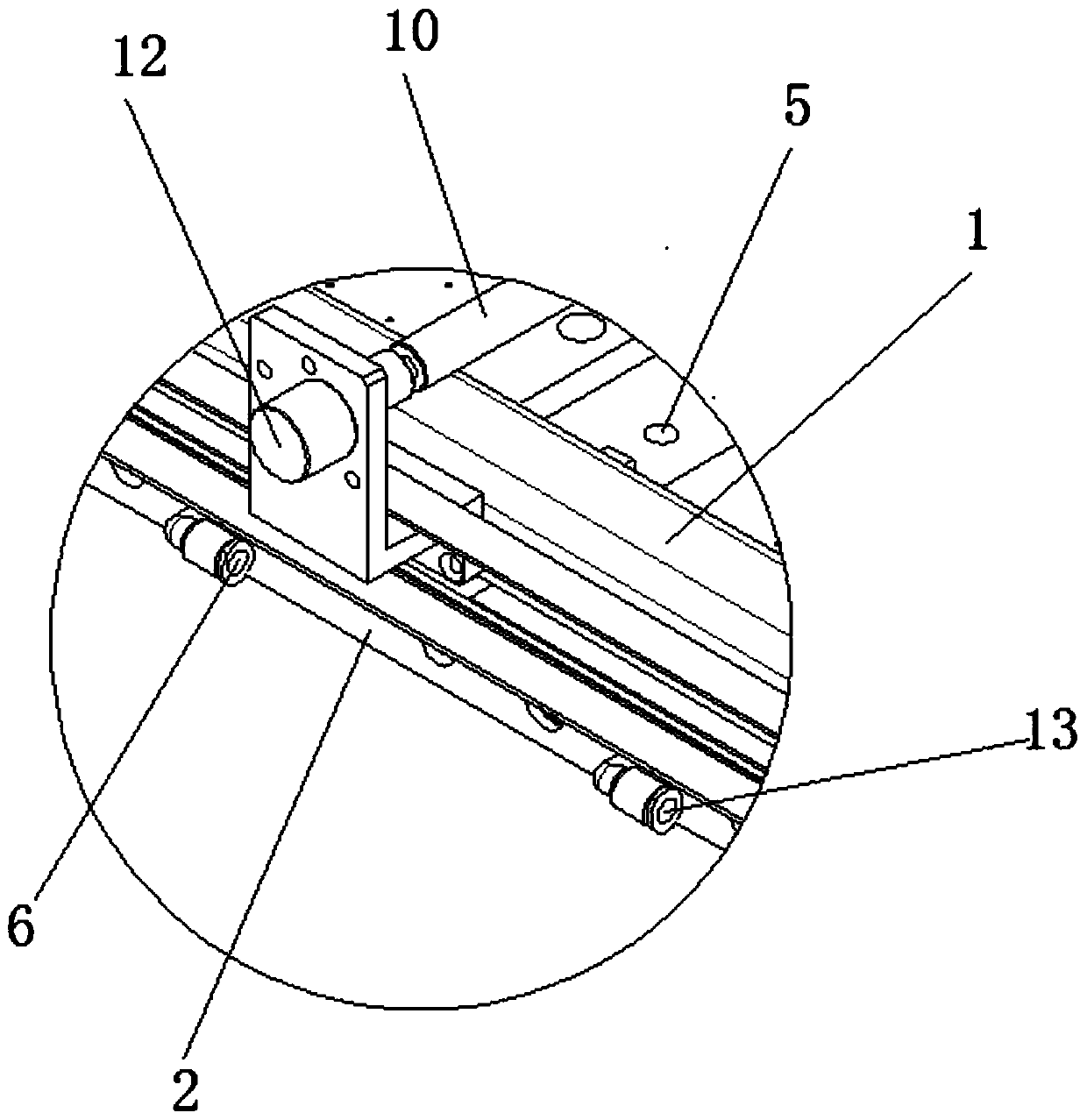

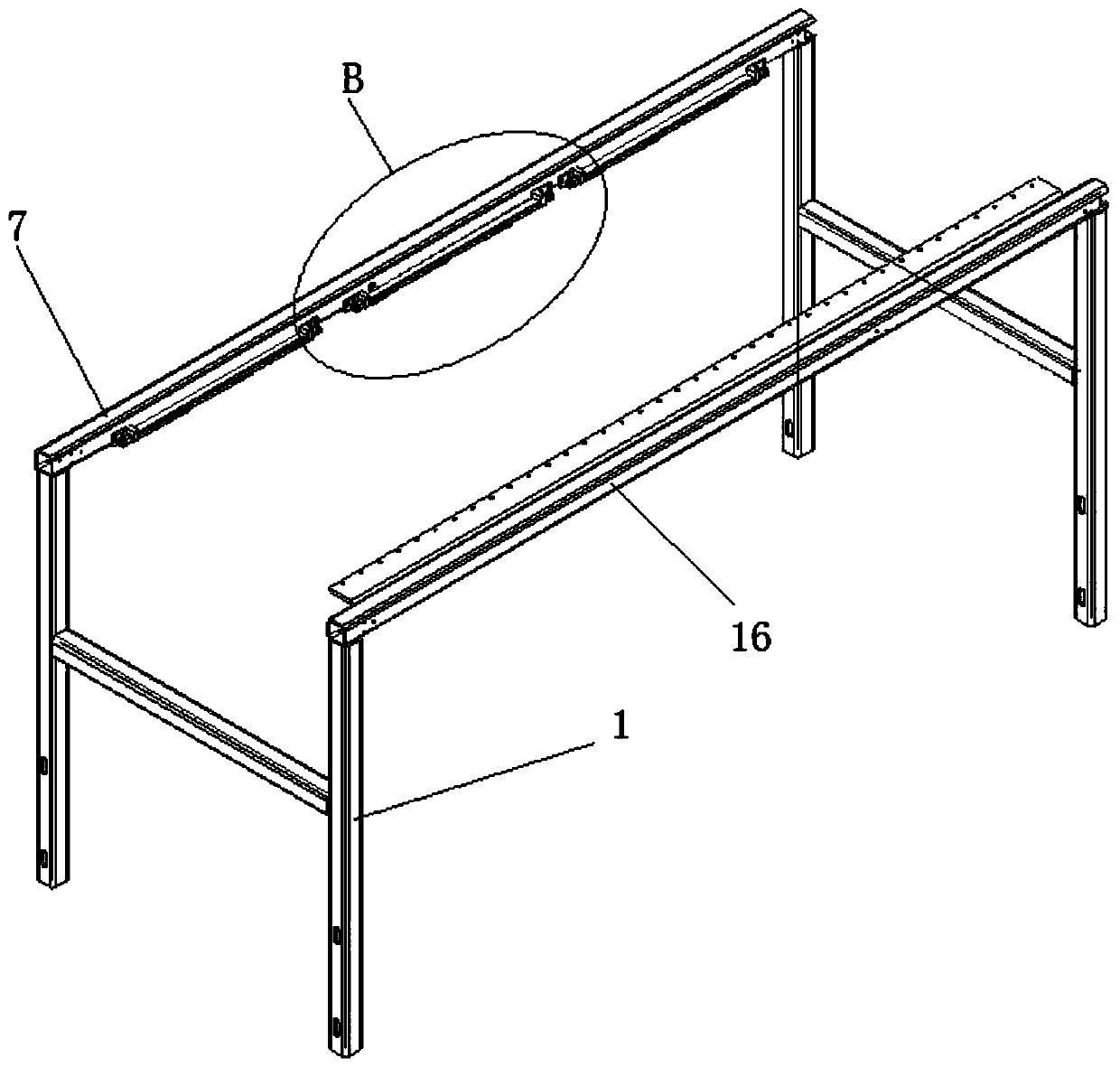

[0023] Such as figure 1 As shown, a kind of anti-scratch drilling device for thick paper after printing, including a foot 1, a workbench 2 and a fixing frame. The fixed frame is fixed on the top of the support foot 1, the worktable 2 is on the guide rail of the drilling machine and corresponds to the position below the fixed frame, and the workbench 2 can move toward the fixed frame along the guide rail of the drilling machine. The two sides slide horizontally, and the workbench 2 is provided with sliders 3 that can slide horizontally toward both ends of the fixing frame. Linear guide rails 14 are provided axially on the workbench 2 for the slider 3 to slide horizontally toward both ends of the fixing frame. Corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com