Mold grinding and cleaning device

A technology for cleaning devices and molds, applied in the field of molds, can solve the problems of mold damage and low efficiency, and achieve the effect of less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

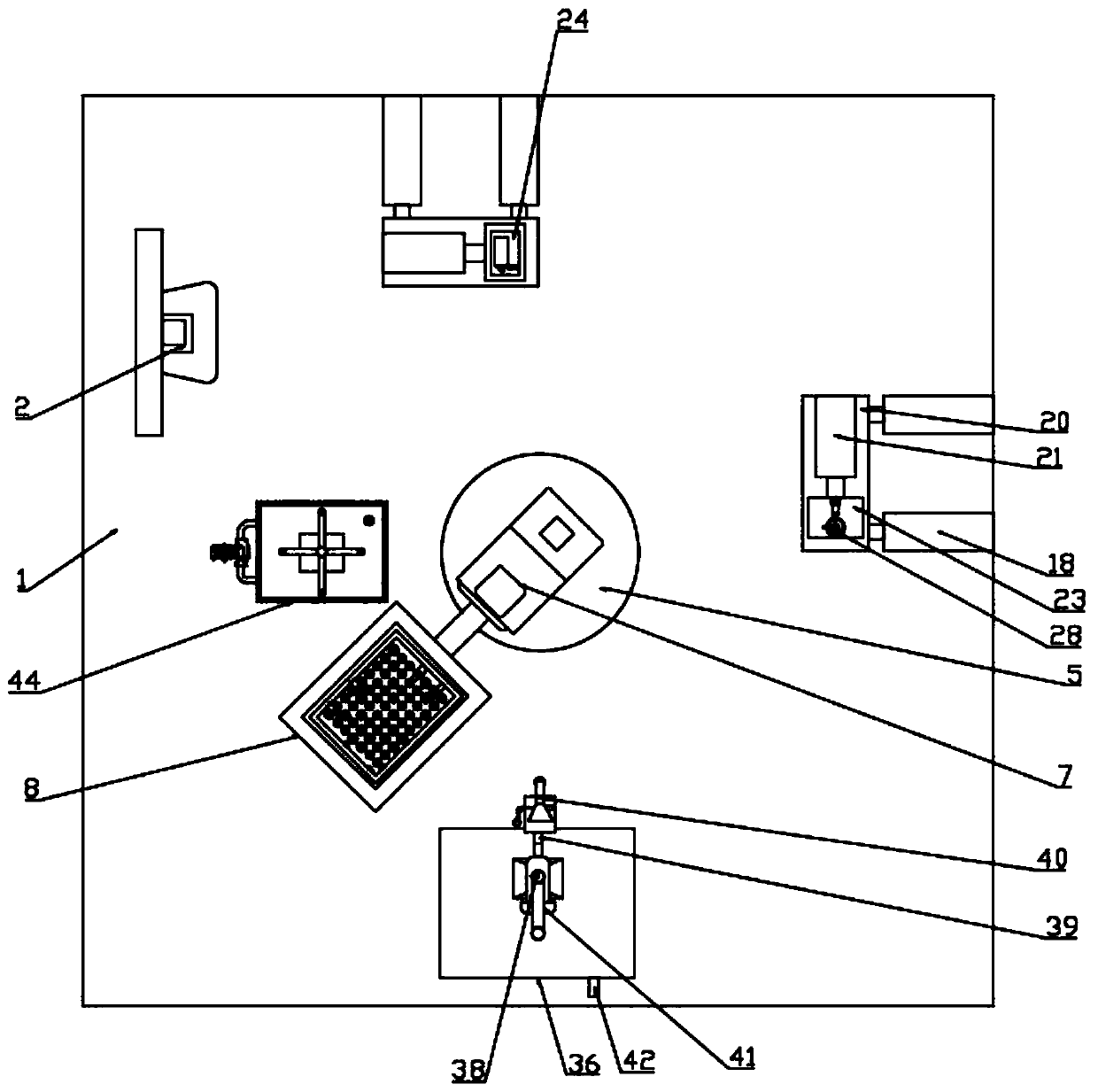

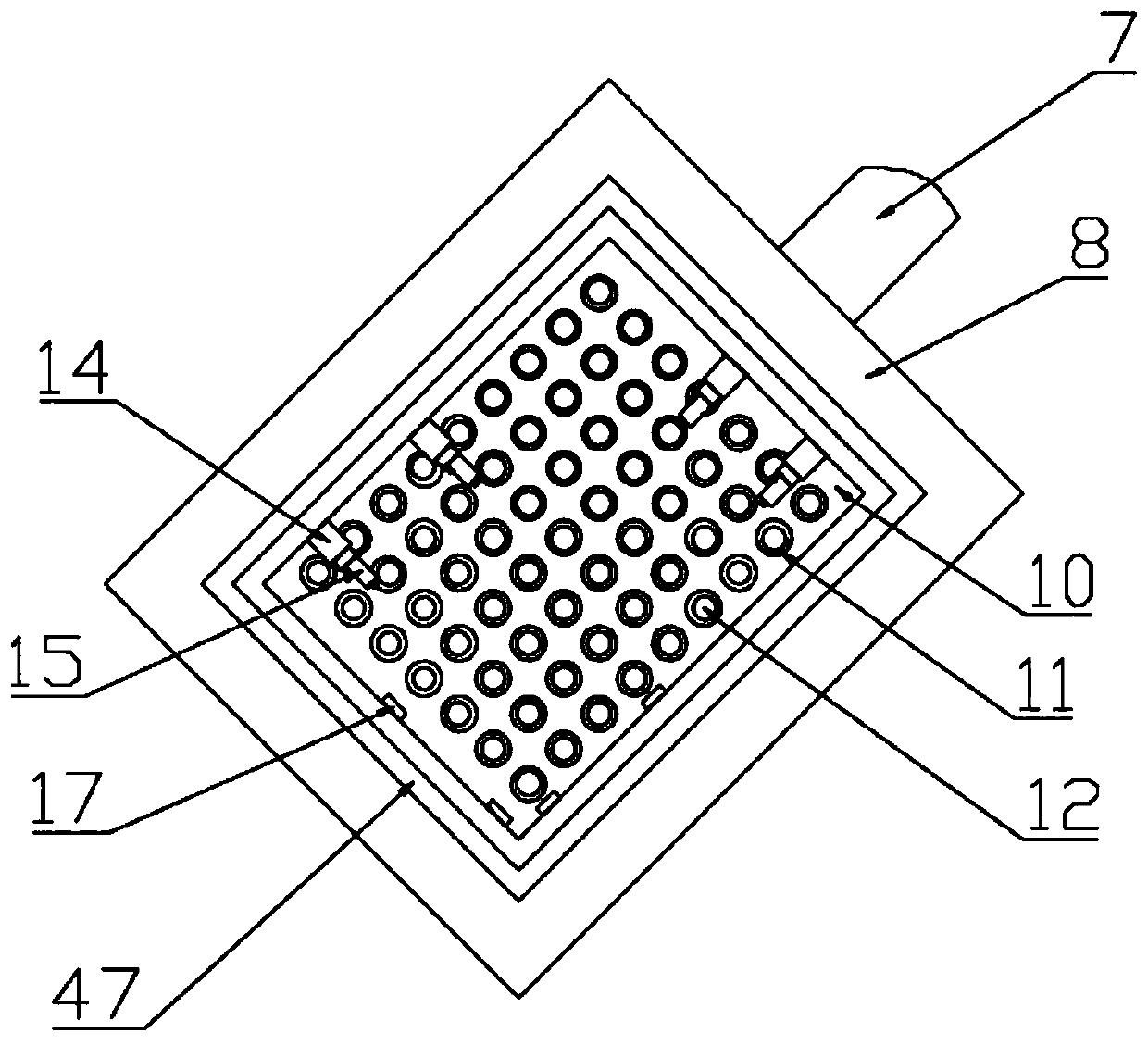

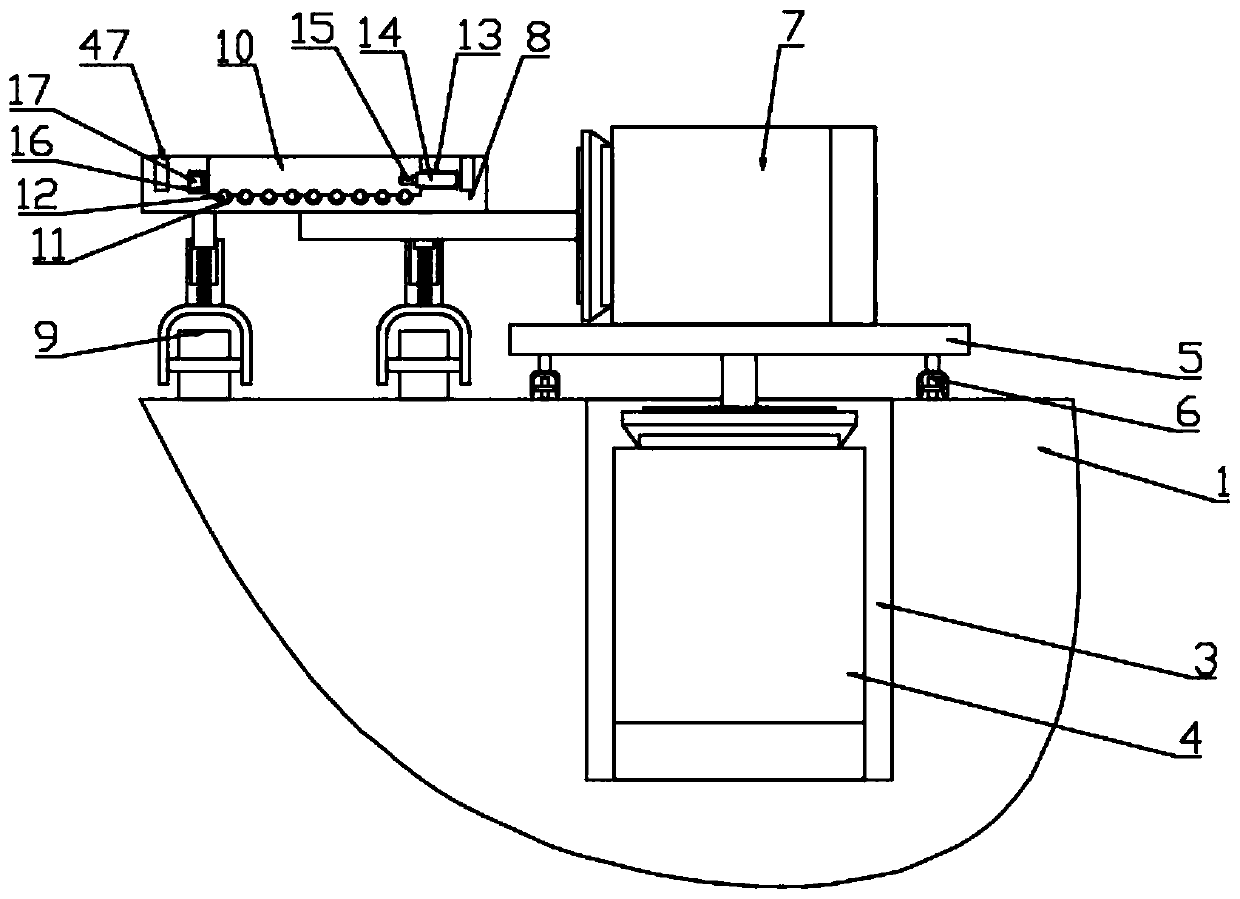

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-10 shown.

[0028] In this embodiment, the first step is to turn over the mold: turn on the power, input the corresponding injection mold model in the controller 2, place the injection mold in the holding groove 10, and start the small electric retractable under the control of the controller 2 The rod 14 is extended to push the injection mold to one side of the holding groove 10, the spherical ball 12 can reduce the friction, and the pressure is sensed by the pressure difference sensor 17. When it reaches a certain level, the controller 2 controls to start the first An electromagnet 15 attracts the injection mold, closes the small electric telescopic rod 14, starts the second servo motor 17 to rotate at a certain angle, turns over the holding bucket 8, and rotates the spring telescopic wheel 9 to the top. After the mold is placed, the device can automatically fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com