Process control numerical control machining technology card design method

A technology of card design and processing technology, which is applied in the direction of printed matter and printing, can solve problems such as unclear technical preparation work, poor process checkability, and processing procedures that cannot be effectively traced back to management and control, so as to improve operability and checkability performance and improved operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

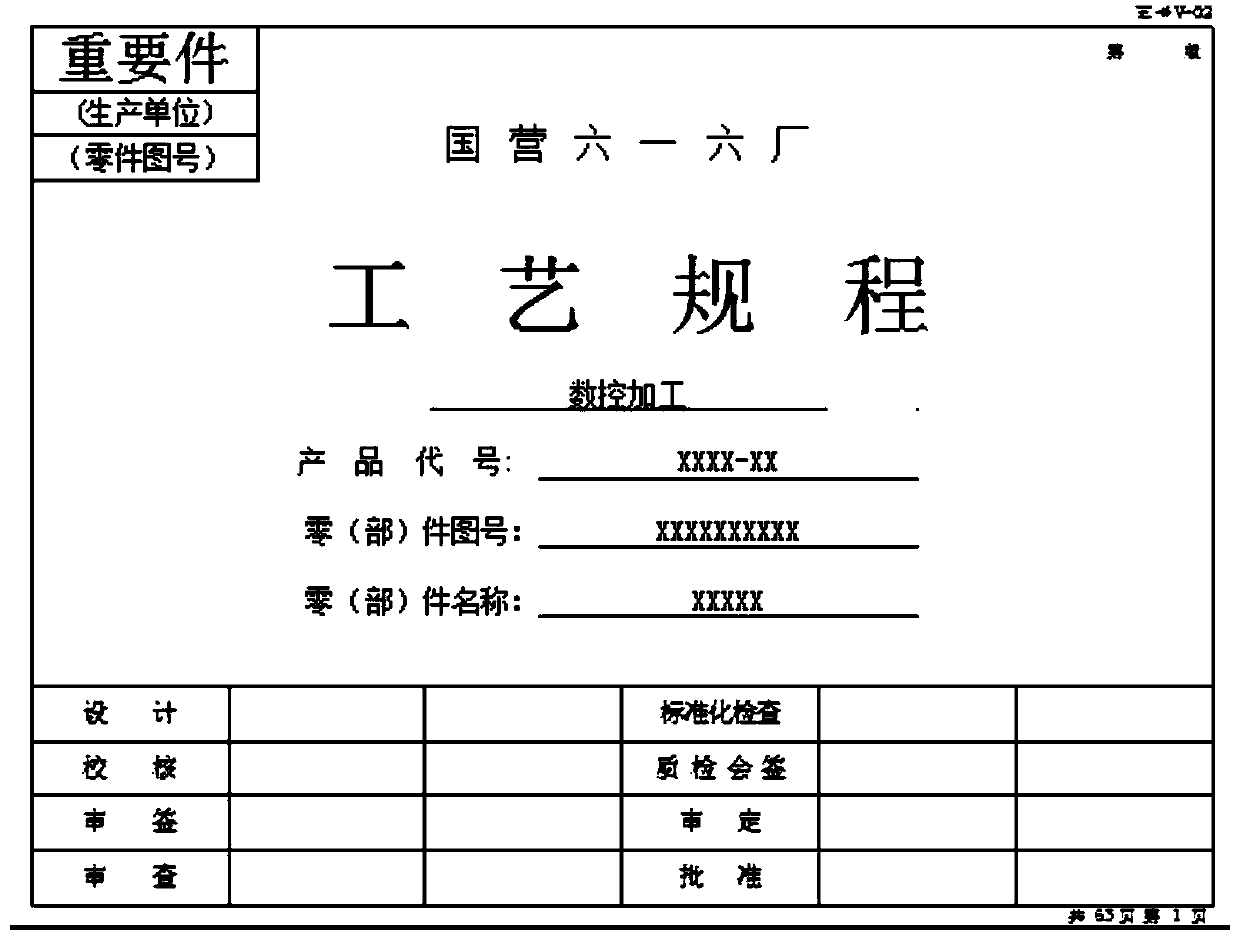

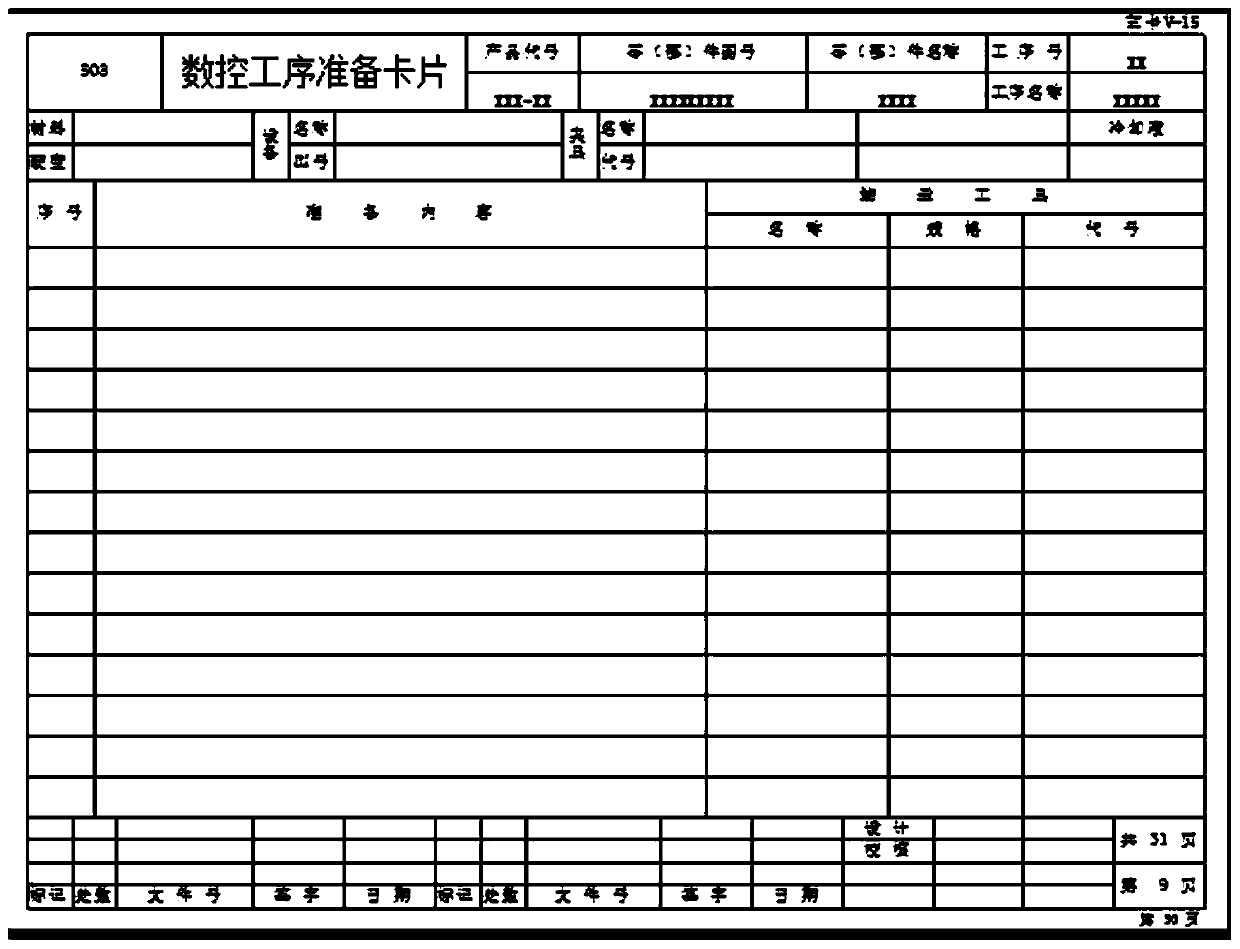

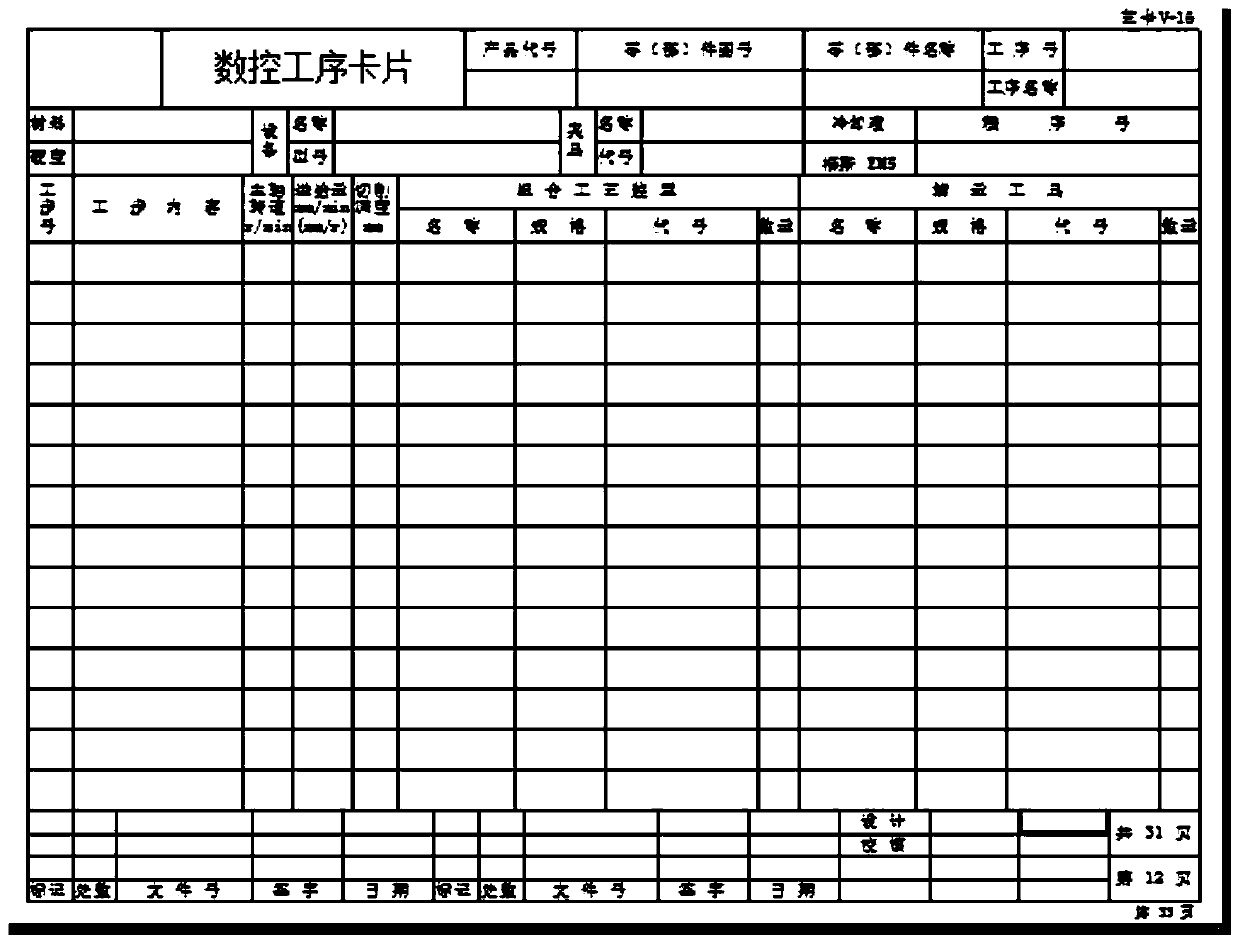

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Technology is the main basis for product production. Scientific and reasonable technology is the decisive factor for the production of high-quality products, the reflection of objective laws, and the basis for operators to perform correct processing operations in production. In particular, the objects processed by CNC equipment are basically high-precision parts, and one-time clamping of parts can complete the processing of multiple parts such as drilling, milling, boring, and threading, which is impossible for ordinary equipment. For this reason, the accuracy verification of CNC equipment, parts clamping method and alignment, machine tool zero point setting and inspection rate of processed dimensions are particularly important to be reflected in the process. The standard design of the NC process specification is mainly composed of the cover of the NC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com