An environmentally friendly water-based aluminum foil stamping fluid

A stamping fluid and water-based technology, applied in the field of lubricating oil, can solve the problems of high energy consumption, unfavorable environmental protection, and affecting the energy consumption of the whole machine, and achieve the effects of small impact, excellent comprehensive performance, and low residual rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

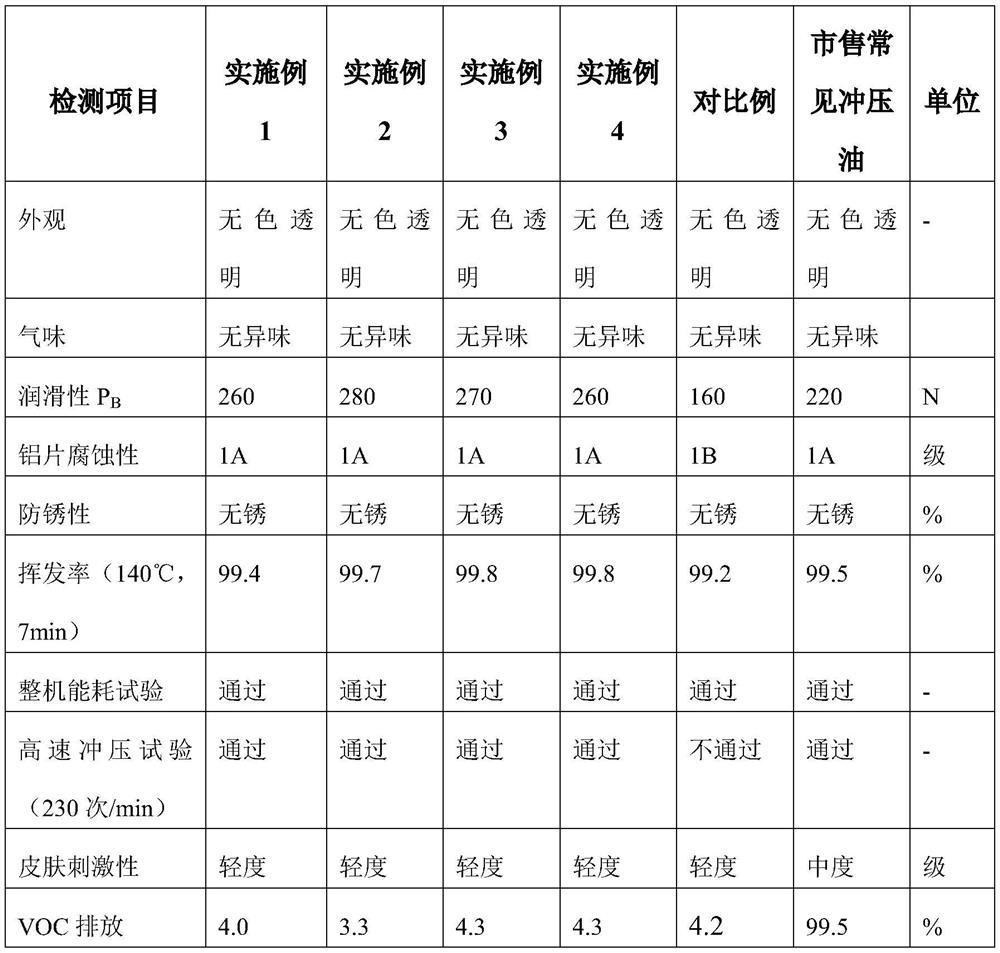

Examples

Embodiment 1

[0026] A kind of environment-friendly water base aluminum foil stamping liquid, comprises the raw material of following percentage by weight:

[0027] Lubrhophos LP700 is 0.05%, Rhodafac ASI80 is 0.001%, L190 is 0.05%, Nonidet SF-5 is 0.05%, diethylene glycol 4%, N-methyl monoethanolamine 0.4%, and distilled water is added to 100%.

Embodiment 2

[0029] A kind of environment-friendly water base aluminum foil stamping liquid, comprises the raw material of following percentage by weight:

[0030] VEG-ESTER TM GY300 is 0.05%, Korantin LUB is 0.001%, TAT730 is 0.06%, TomaKleen G-12 is 0.05%, glycerol 3%, N-methyldiethanolamine 0.3%, and supplemented with distilled water to 100%.

Embodiment 3

[0032] A kind of environment-friendly water-based aluminum foil stamping liquid, comprises the raw material of following weight percent:

[0033] Rhodafac ASI80 is 0.05%, CI2107 is 0.07%, Nonidet SF-5 is 0.05%, diethylene glycol 2%, propylene glycol 2%, diglycolamine 0.3%, and supplemented with distilled water to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com