A new type of cotton blender

A cotton blending machine, a new type of technology, is applied in the direction of fiber mixing, textile and paper making, opening and cleaning with suction device, etc. It can solve the problems of poor mixing effect, escape, low degree of automation, etc., and improve the uniformity of mixing , good mixing uniformity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

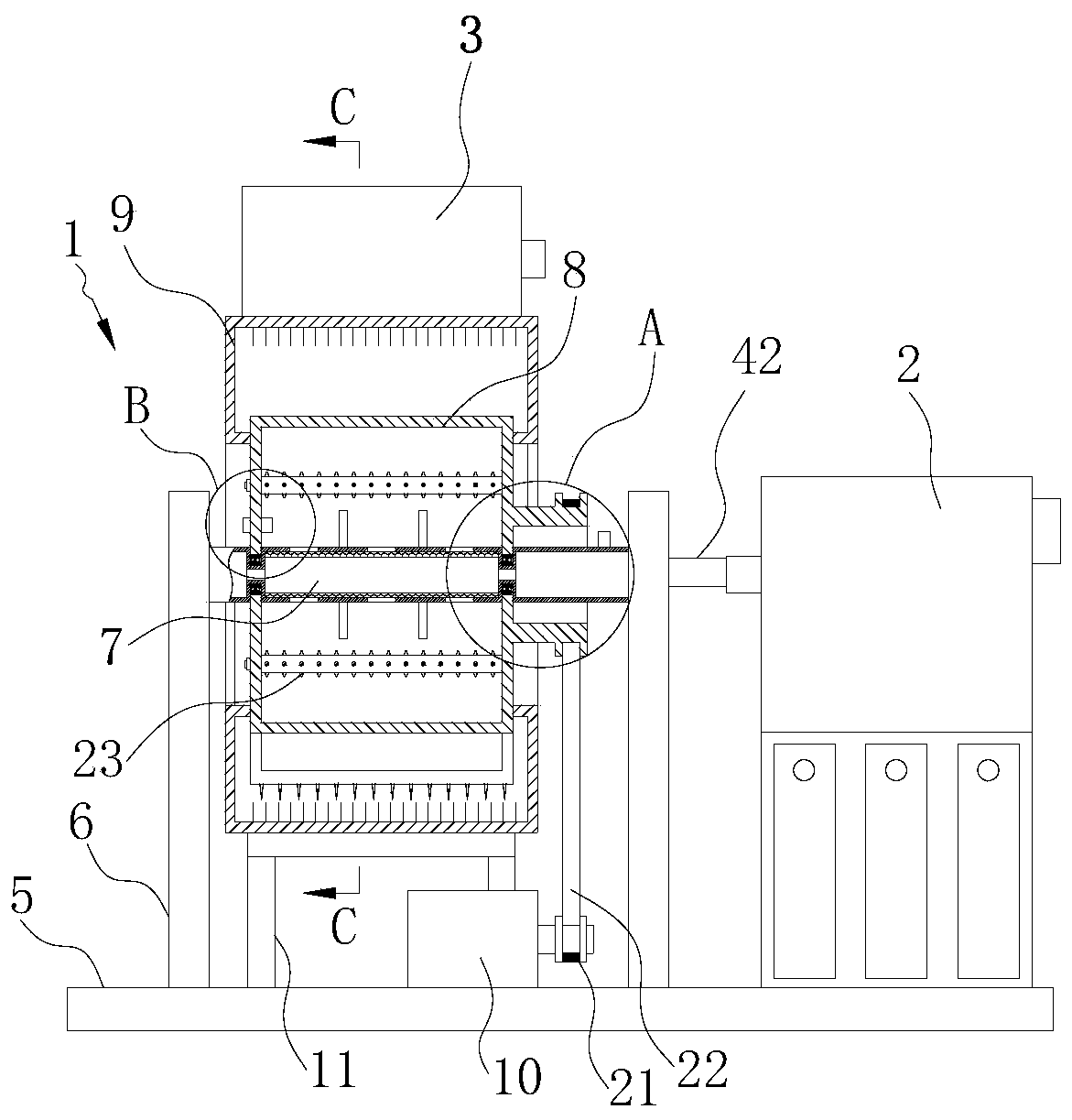

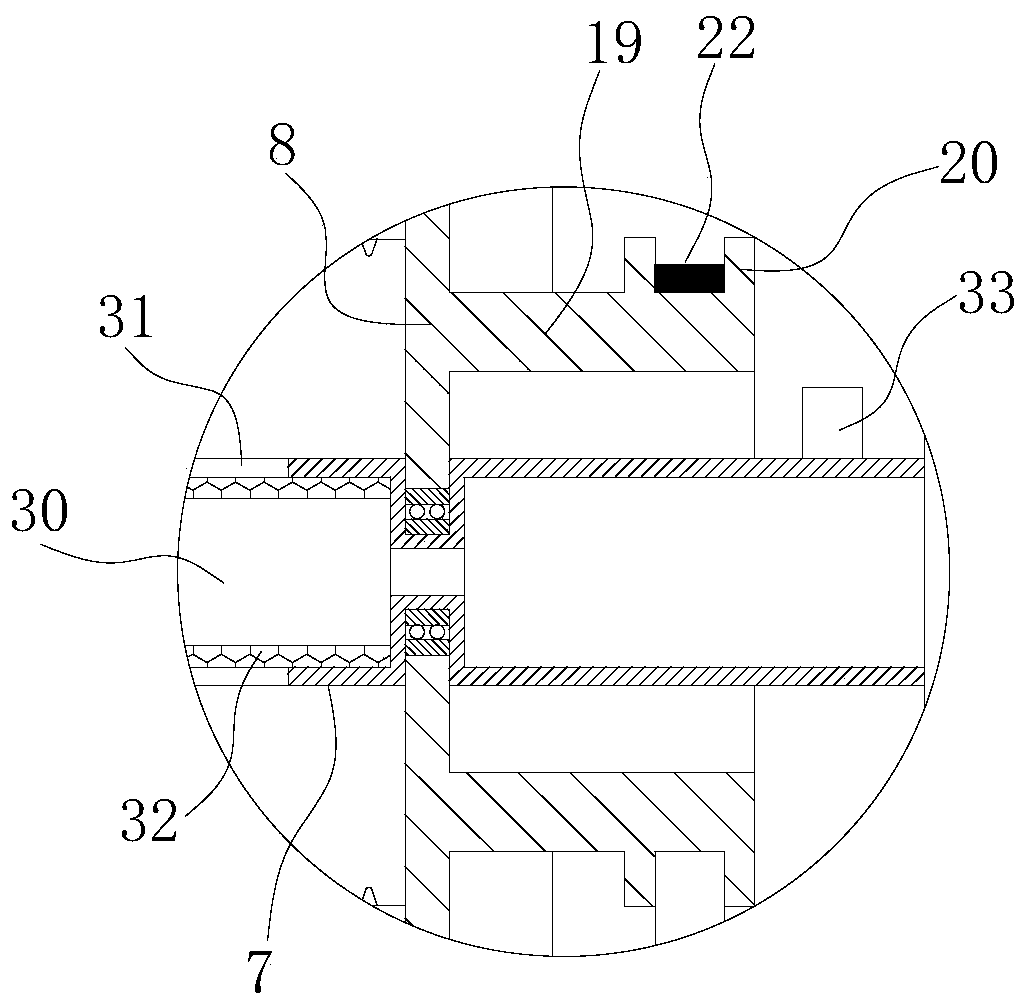

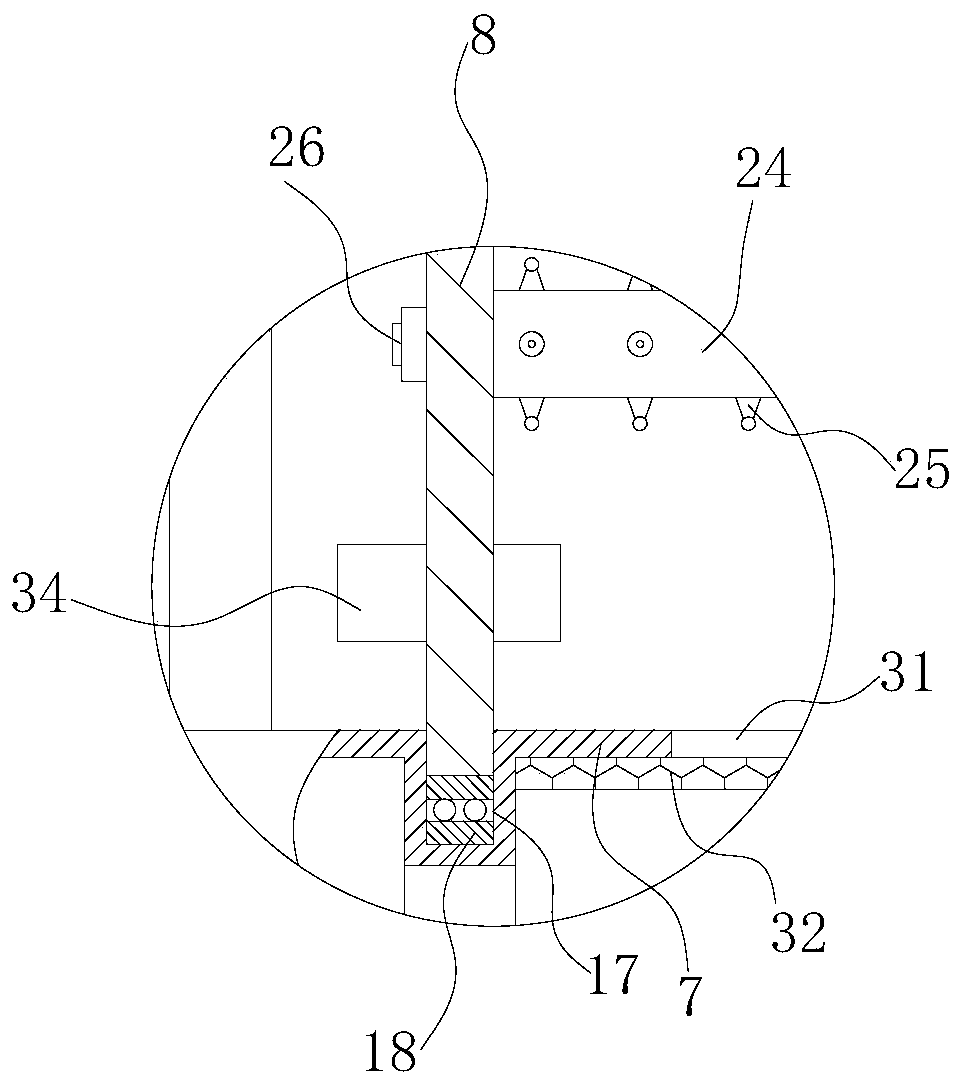

[0023] like Figure 1-7 A new type of cotton blending machine shown includes a frame, a cotton blending machine main body 1 arranged on the frame, and a dust removal device 2 for cleaning the flying flowers generated by the cotton mixing machine main body 1 . A feed hopper 3 is arranged on the top of the main body 1 of the cotton blender, and the feed hopper 3 communicates with the feed port 4 of the main body 1 of the cotton blender. The frame includes a chassis 5 and two vertical side frames 6 arranged on the chassis 5 . That is to say, the present invention generally comprises cotton mixer main body 1, dust removal device 2 and feed hopper 3 and is formed, and cotton mixer main body 1 is used for mixing various fiber raw materials, and dust removal device 2 is used for mixing process produced Impurities such as dust and broken fibers are removed, and the feeding hopper 3 is used to improve the automation of feeding the cotton blender 1. The improvement of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com