Steam brush

A steam brush and steam technology, applied in the field of steam brush, can solve the problems of low water vapor drying rate, etc., and achieve the effects of increasing the drying rate, reducing excess moisture, and solving high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is further described in detail through specific implementation methods:

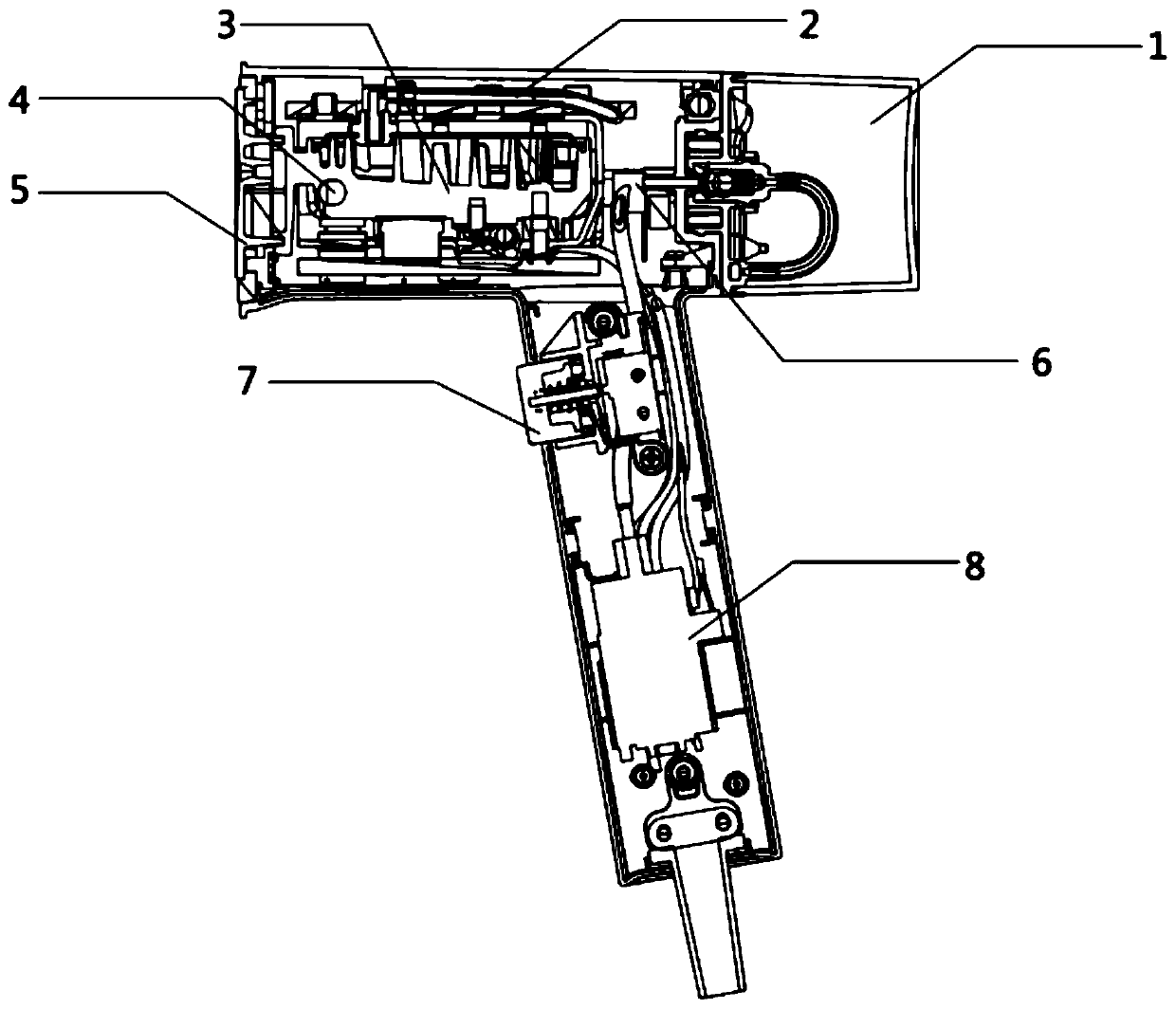

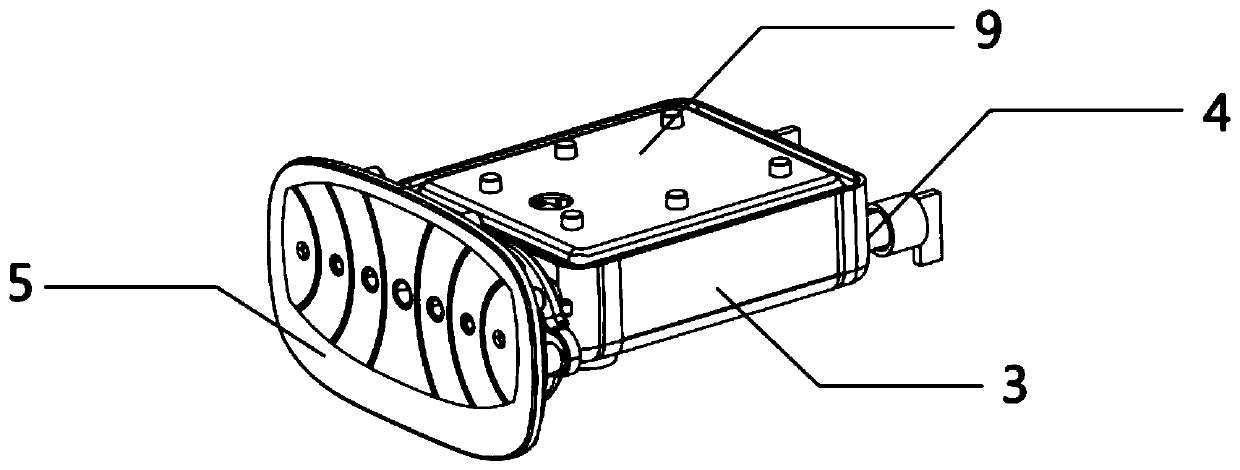

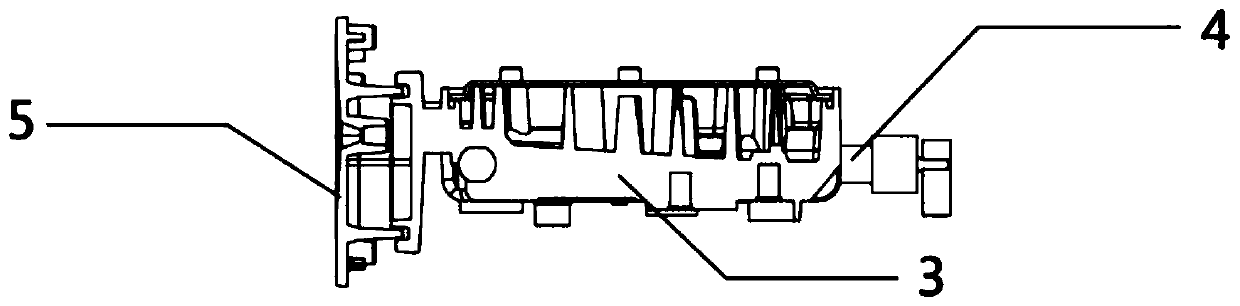

[0038] The reference signs in the drawings of the description include: water tank 1, water inlet pipe 2, heating element 3, electric heating pipe 4, panel 5, water outlet pipe 6, steam button 7, electromagnetic pump 8, gasification cover 9, partition 10, outlet Air port 11, extension part 12.

[0039] The embodiment is basically as attached figure 1 Shown: the steam brush in this embodiment includes a casing and components such as a water tank 1 installed in the casing, an electromagnetic pump 8, a heating element 3, and a vaporization cover 9. Wherein, the heating element 3 is directly connected with the panel 5, and the panel 5 is blocked at the left end of the casing to form a complete outer wall of the product together with the casing. An electric heating tube 4 is embedded in the heating body 3 , and the electric heating tube 4 runs through the heating body 3 from left to righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com