Glue for high-permeability waterproof fabric, high-permeability waterproof fabric and making method thereof

A moisture-permeable, waterproof, fabric technology, applied in textiles and papermaking, etc., can solve problems such as destroying the moisture-permeability of fabrics, and achieve the effect of simple and easy production method, convenient operation and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

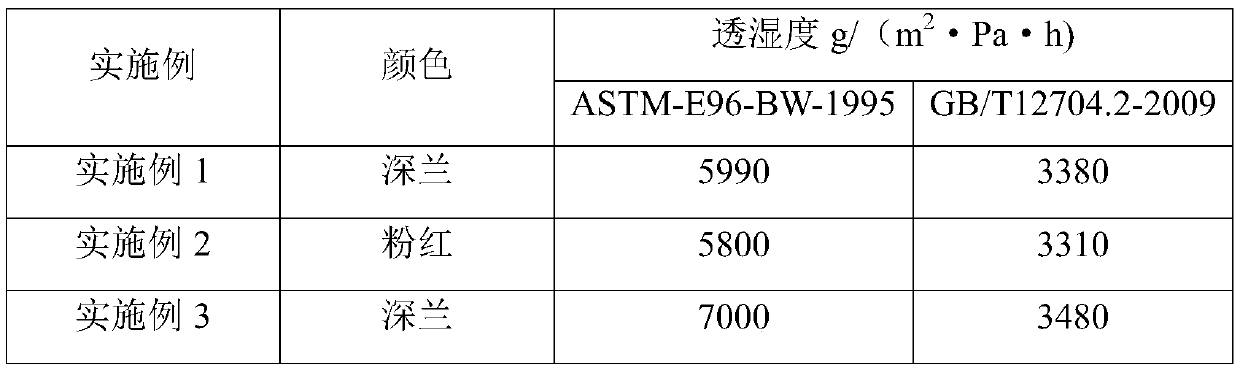

Examples

Embodiment 1

[0037] Adhesive for high moisture-permeable waterproof fabrics, including primer and surface glue, said primer includes the following components in parts by weight: 100 parts of PU resin 2355, 4 parts of bridging agent S069, 2 parts of accelerator S061, acetic acid 15 parts of methyl ester, 1.5 parts of bridging agent 557;

[0038] The surface glue includes the following components in parts by weight: 100 parts of PU resin 2133, 10 parts of acrylic resin, 1 part of slip agent JYL-201, 8 parts of matting agent, and 22 parts of methyl acetate.

[0039] The preparation method of the glue for the high moisture-permeable waterproof fabric comprises the following steps:

[0040] Preparation of primer: According to the above ratio, mix and stir the PU resin and methyl acetate evenly, and add bridging agent I, accelerator and bridging agent II sequentially while stirring. After adding, continue to stir for 15 minutes, and test the viscosity to reach 23,000 CPS, pass through a 100-mes...

Embodiment 2

[0047] Adhesive for high moisture-permeable waterproof fabrics, including primer and surface glue, the primer includes the following components in parts by weight: 90 parts of PU resin, 2 parts of bridging agent S069, 1 part of accelerator S061, acetic acid 12 parts of methyl ester, 1 part of bridging agent 557;

[0048] The surface glue includes the following components in parts by weight: 90 parts of PU resin 2133, 8 parts of acrylic resin, 0.5 parts of slip agent JYL-201, 5 parts of matting agent, and 20 parts of methyl acetate.

[0049] The preparation method of the glue for the high moisture-permeable waterproof fabric comprises the following steps:

[0050] Preparation of primer: According to the above ratio, mix and stir the PU resin and methyl acetate evenly, and add bridging agent I, accelerator and bridging agent II sequentially while stirring. After adding, continue to stir for 10 minutes, and test the viscosity to reach 22,000 CPS, pass through a 100-mesh sieve to...

Embodiment 3

[0057] Adhesive for high moisture-permeable waterproof fabrics, including primer and surface glue, the primer includes the following components in parts by weight: 110 parts of PU resin 2355, 5 parts of bridging agent S069, 3 parts of accelerator S061, acetic acid 17 parts of methyl ester, 2 parts of bridging agent 557;

[0058] The surface glue includes the following components in parts by weight: 110 parts of PU resin 2133, 12 parts of acrylic resin, 1.5 parts of slippery agent JYL-201, 10 parts of matting agent, and 25 parts of methyl acetate.

[0059] The preparation method of the glue for the high moisture-permeable waterproof fabric comprises the following steps:

[0060] Preparation of primer: According to the above ratio, mix and stir the PU resin and methyl acetate evenly, and add bridging agent I, accelerator and bridging agent II sequentially while stirring. After adding, continue to stir for 15 minutes, and test the viscosity to reach 24,000 CPS, pass through a 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com