Modular assembly frame

A modular and frame technology, applied in building types, buildings, building components, etc., can solve the problems of low bearing capacity, general seismic performance, poor integrity of each module, etc., to achieve good integrity and firm connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

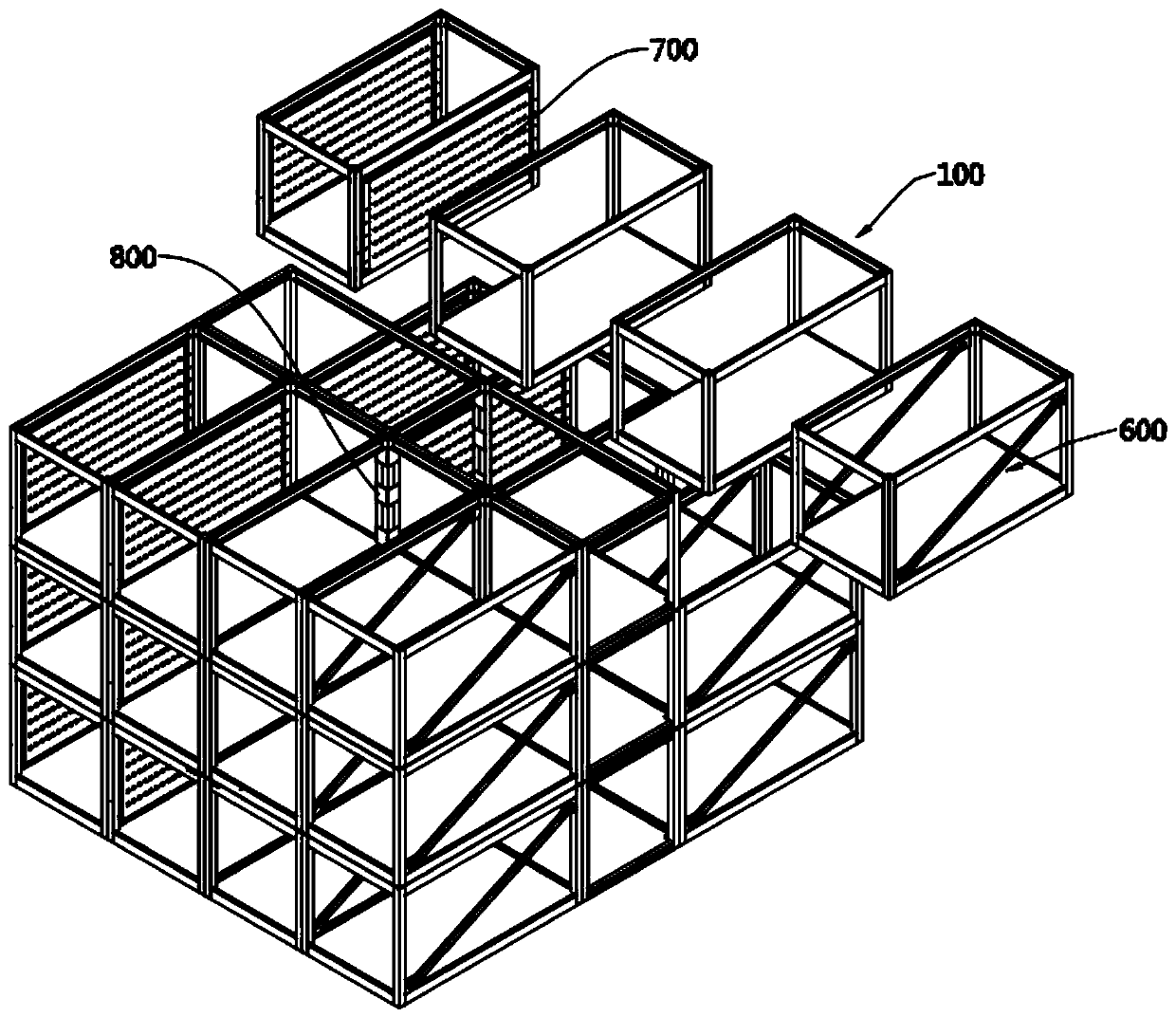

[0055] This embodiment provides a modular assembly frame, as attached figure 1 As shown in , the modular assembly frame includes a plurality of modular units 100 assembled together, and the plurality of modular units 100 are fixed by connectors, the first connector 222, the second connector 212 and other connectors in this embodiment It can be a screw rod or a bolt, or other connecting devices that match through holes.

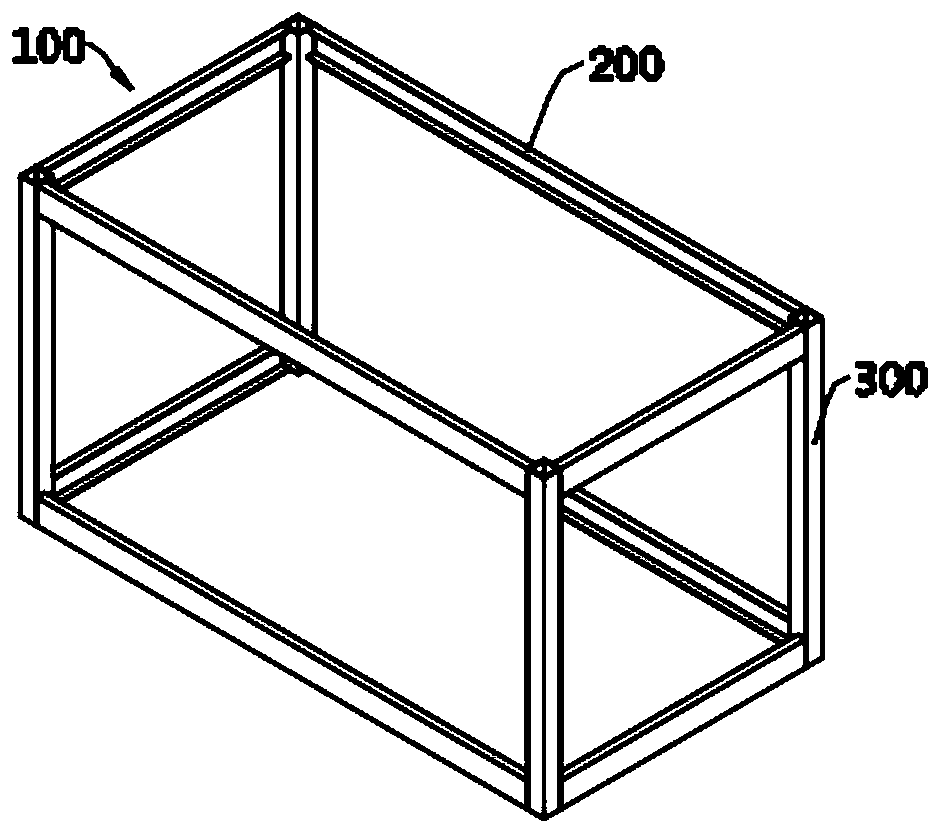

[0056] Please refer to the attached figure 2 , which shows an independent modular unit 100, which is a three-dimensional frame, including a first load-bearing member and a second load-bearing member, wherein the first load-bearing member mainly bears vertical loads, and the second load-bearing member mainly bears lateral loads load. The first load-bearing member includes a plurality of modular columns 300 , and the second load-bearing member includes a plurality of modular beams 200 .

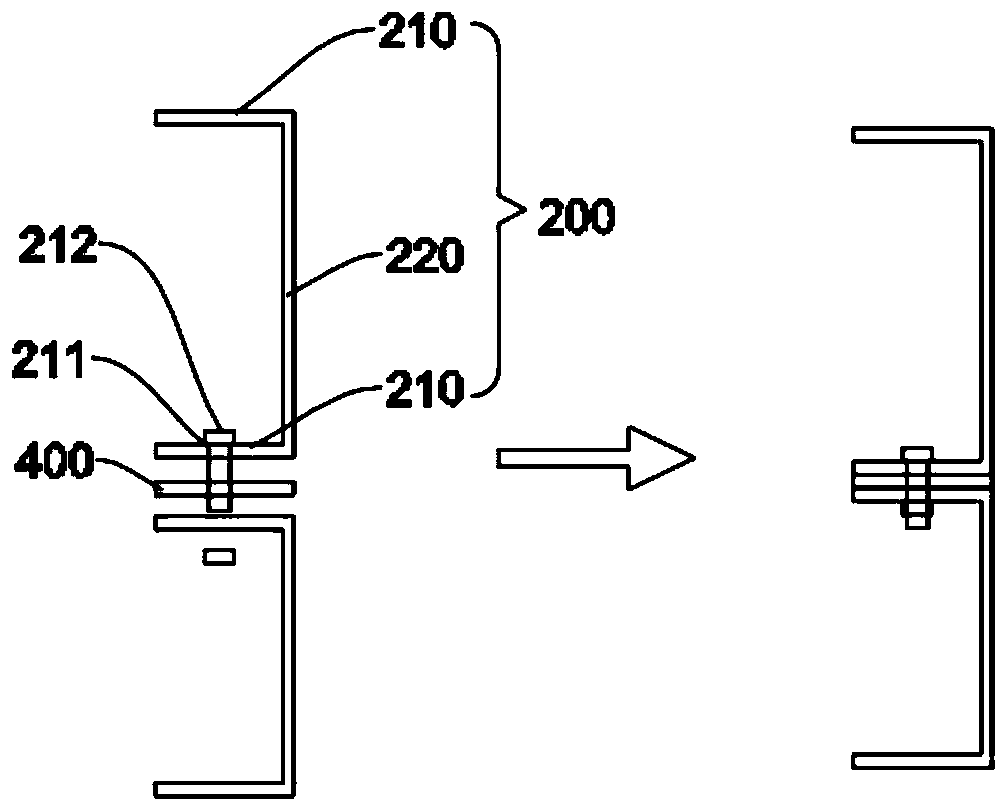

[0057] In this embodiment, as attached figure 2 The shown modular un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com