Induction cooker testing facility

A technology for testing equipment and induction cookers, applied in lighting and heating equipment, household stoves/stoves, electric heating fuels, etc., can solve the problems of large test errors, large manual influences, large time errors, etc., to improve accuracy and avoid manual labor. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

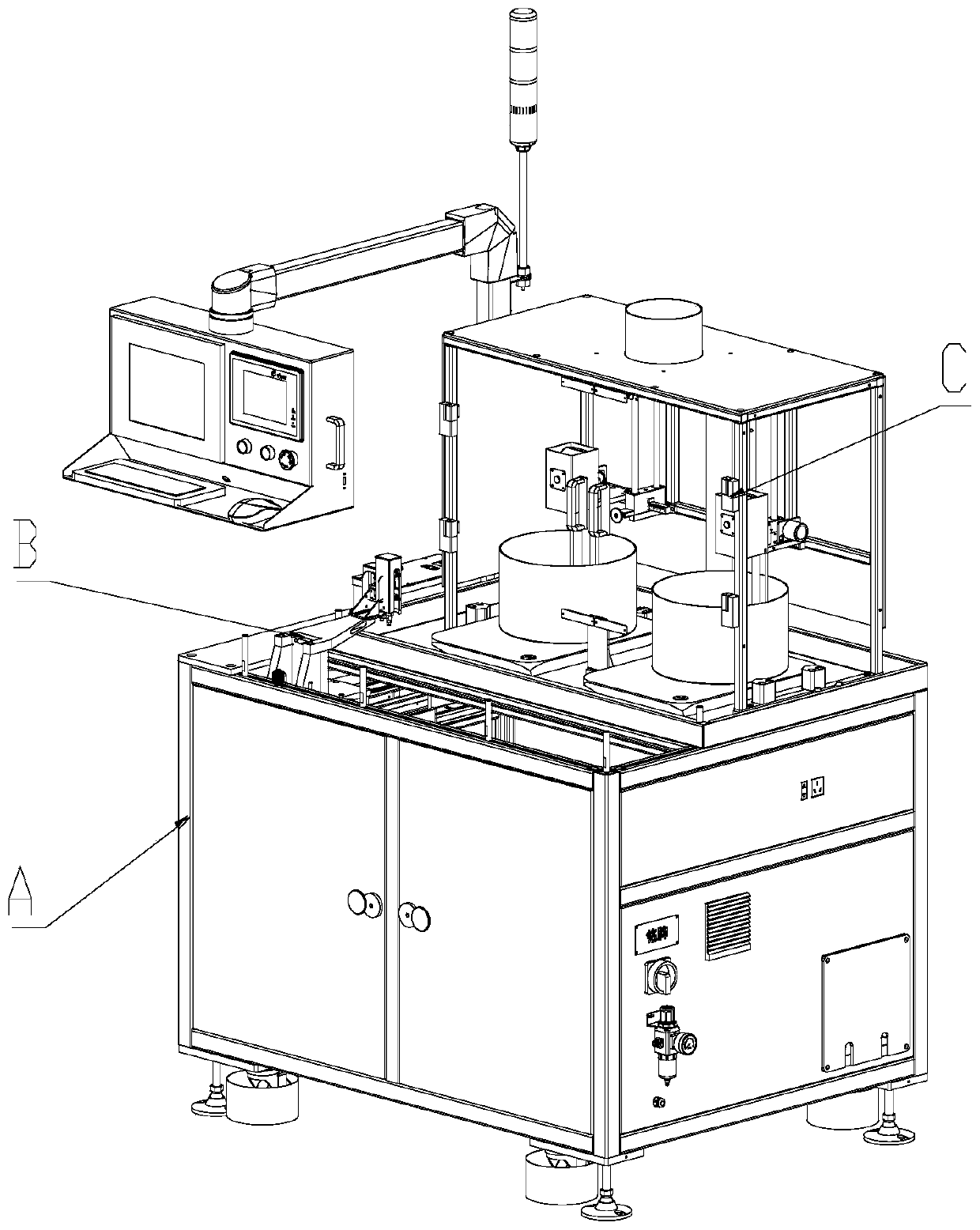

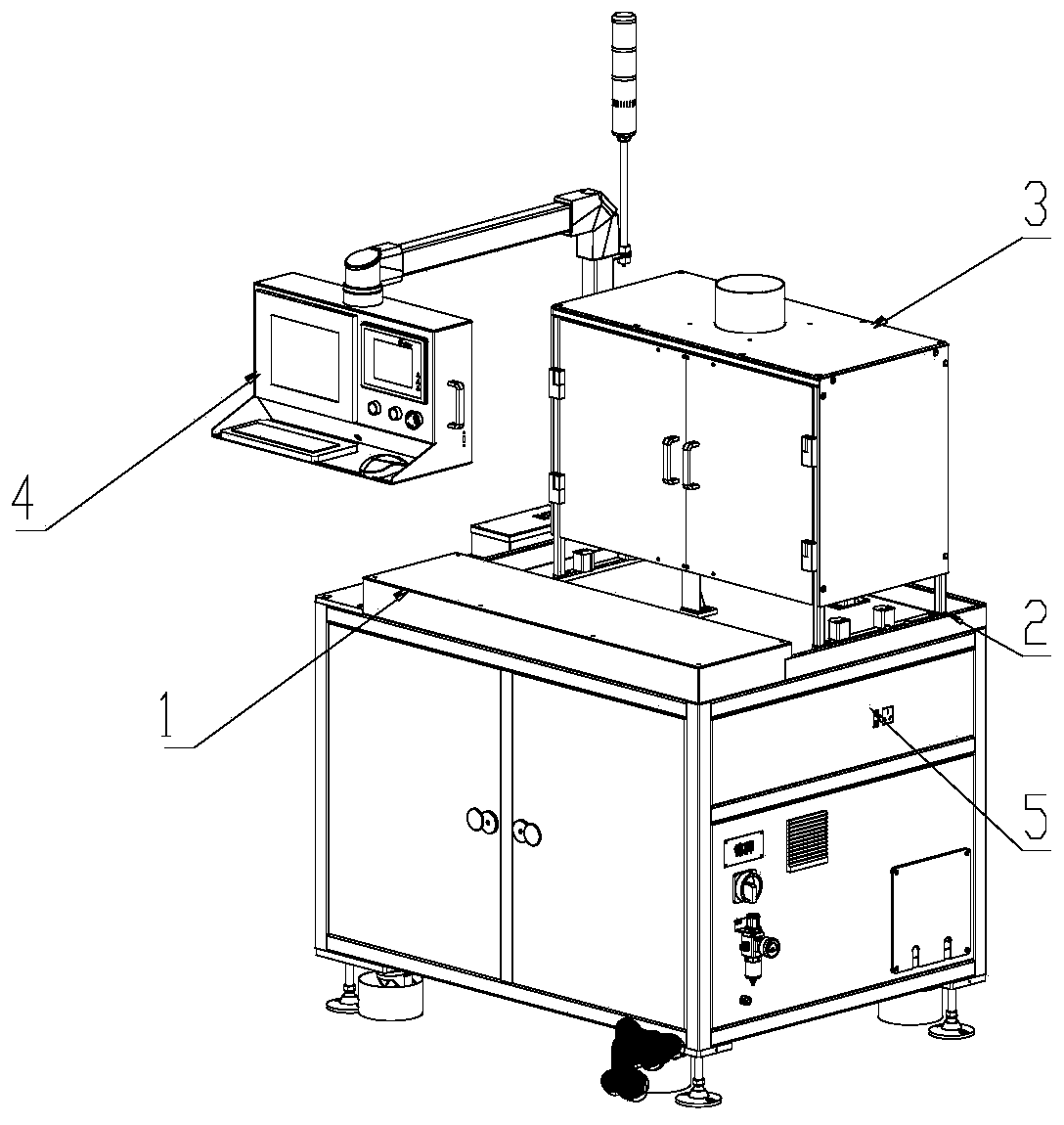

[0024] The electromagnetic oven test equipment used in the present invention includes: a frame A with functions of waterproofing, drainage, and steam drainage, a touch module B for controlling the induction oven, and a monitoring module C for monitoring the state of the induction oven.

[0025] The frame A includes a waterproof casing 1, a drain tank 2, a water vapor shield 3, an operation panel 4, and a socket 5.

[0026] The touch module B includes a stylus 6 , an X movement axis 7 and a Y movement axis 8 . With programming function, test steps can be written.

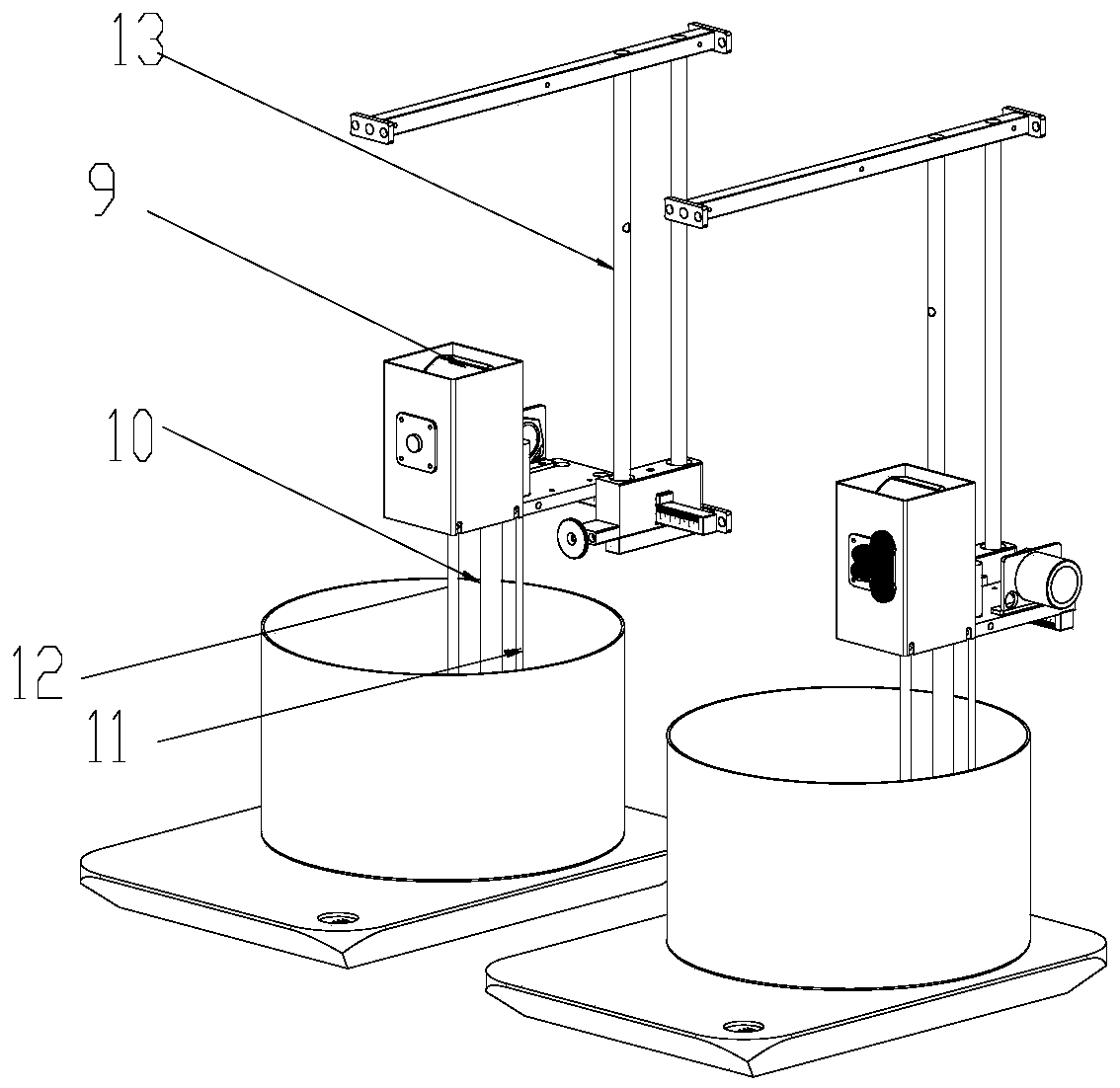

[0027] The monitoring module C includes a water level control component 9 , an automatic water injection component 10 , a temperature monitoring component 11 , a power monitoring component 12 , and a height adjustment component 13 . With real-time monitoring function, it can query the working status of the induction cooker in real time. Power monitoring assembly 12 is located within rack A. As shown in FIG. The he...

Embodiment 2

[0030] Such as Figure 1-4 The induction cooker test equipment shown includes a rack A, on which an induction cooker is placed, and a monitoring module C is covered outside the induction cooker, and a touch module B is arranged on the front side of the induction cooker. Equipped with a movable pot body.

[0031] The touch module B includes an external shell 1 , and the touch module B also includes a stylus 6 that can move along the X-axis and the Y-axis.

[0032] The touch module B includes an X moving shaft 7, and an X-axis slider driven by a driving device is arranged on the X moving shaft 7 .

[0033] A Y moving shaft 8 is installed on the X-axis slider, and the Y moving shaft 8 is provided with a Y-axis slider driven by a driving device to move along the Y-axis direction, and the stylus 6 is fixed on the Y-axis slider through a linkage mechanism. superior.

[0034] A socket 5 is provided on the side of the frame A, and the device also includes an operation panel 4 exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com