Hot air supply system of steam oven and installation method thereof

A technology of supply system and steam oven, which is applied in the field of mechanical processing, can solve the problems of slow heating speed and uneven heating, and achieve the effect of orderly operation, not easy to aging, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

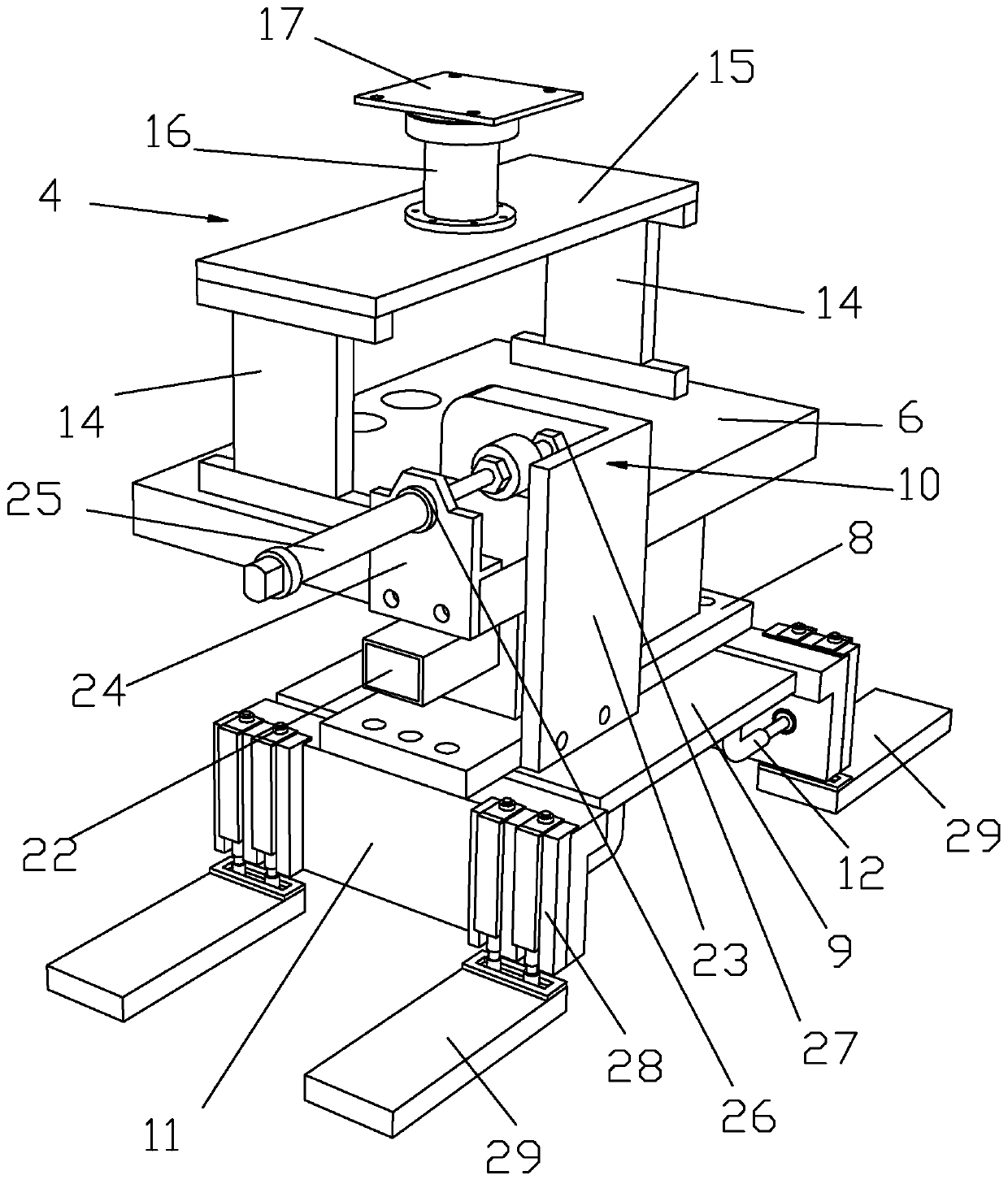

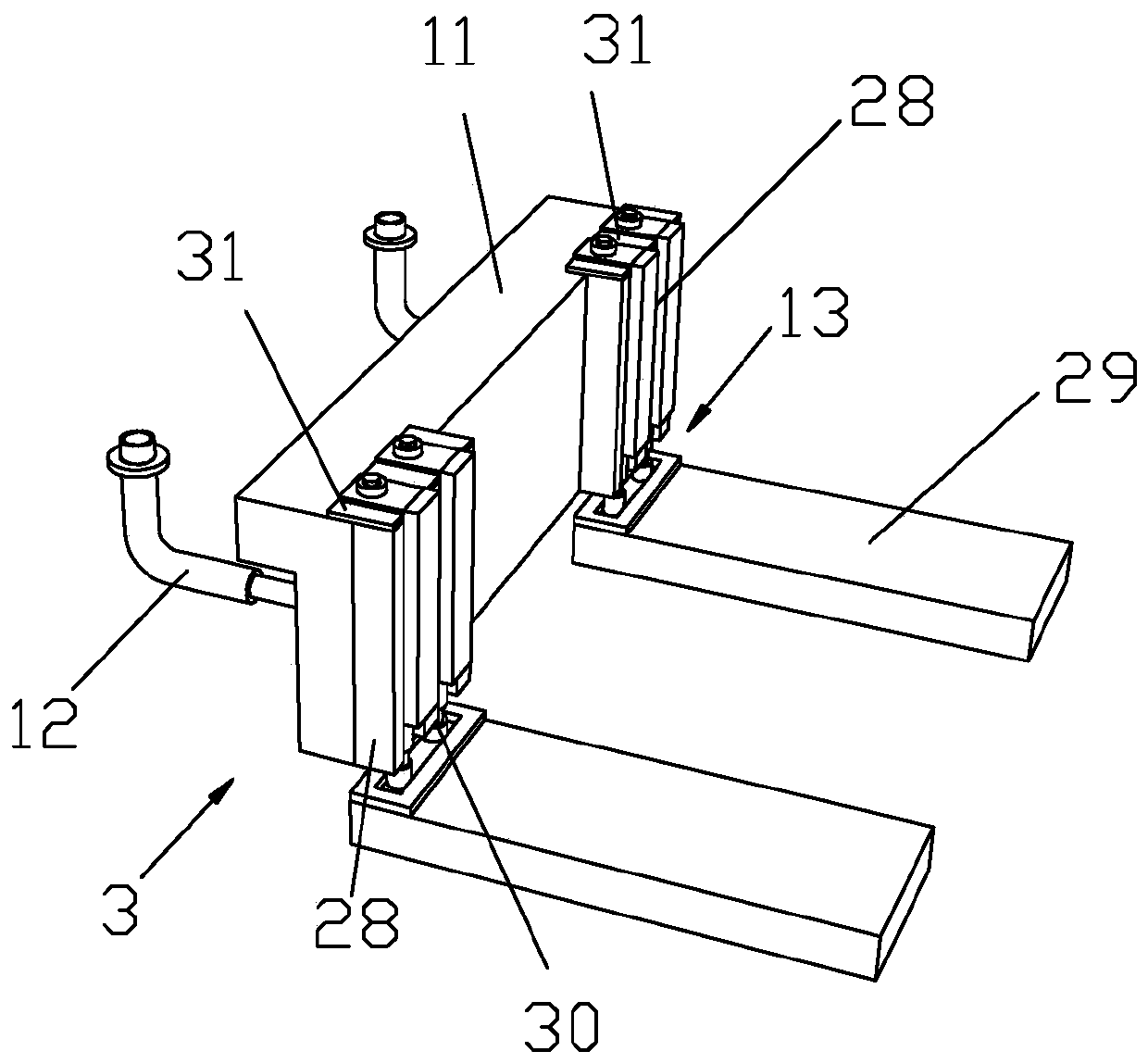

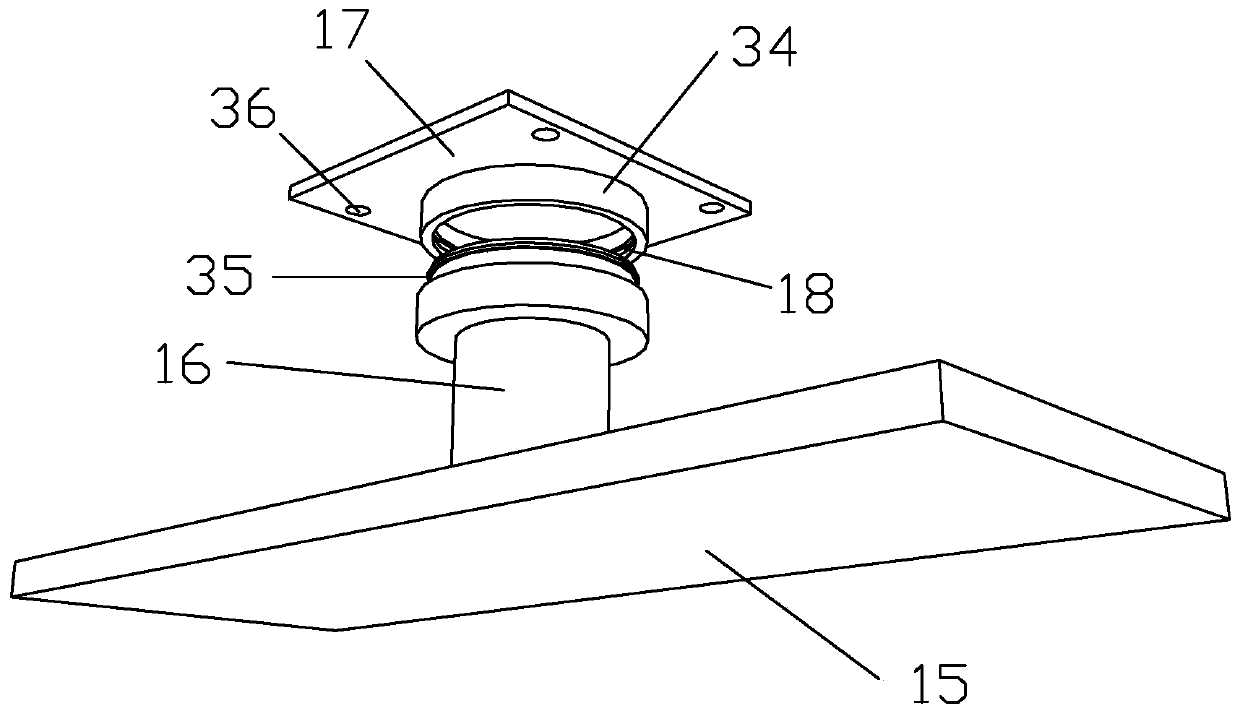

[0040] Such as Figure 1 to Figure 5As shown, it is a hot air supply system for a steaming oven of the present invention, which includes a box body 1, an air inlet system and an air outlet system 3, and also includes a suspension system 4 and a return air system 5. The box body 1 includes a top plate 6 and a heating chamber 7 , the mounting plate 8 and the air deflector 9, the top plate 6 is installed above the heating chamber 7, the top plate 6 is provided with an air inlet passage groove, the mounting plate 8 is installed below the heating chamber 7, and the air deflecting plate 9 is fixedly installed on the mounting plate 8, the inside of the heating chamber 7, the mounting plate 8 and the wind deflector 9 are connected, the air intake system includes a heater 2 and a fan assembly 10, the heater 2 is installed inside the heating chamber 7, and the inside of the heater 2 is provided with The high-temperature pipe 33, the end of the high-temperature pipe 33 extends into the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com