An automatic measuring system for tap water detection

An automatic measurement and tap water technology, which is applied in the application of electromagnetic flowmeters to detect fluid flow, temperature measurement of moving fluids, measurement devices, etc., can solve the problems of control box interference installation, etc., to ensure the drying effect, avoid moisture damage, and facilitate fixing The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

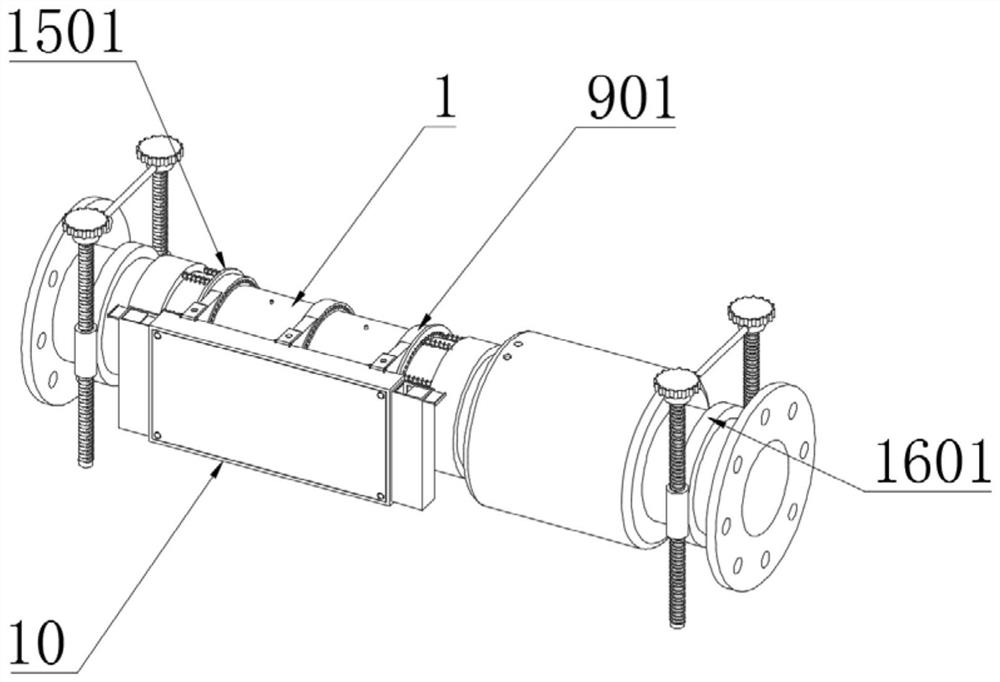

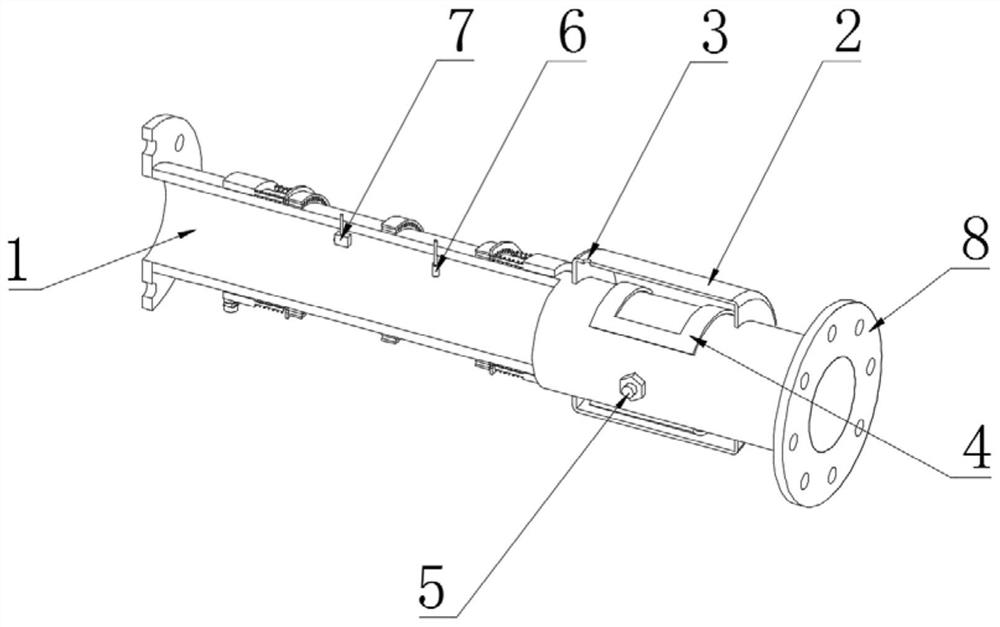

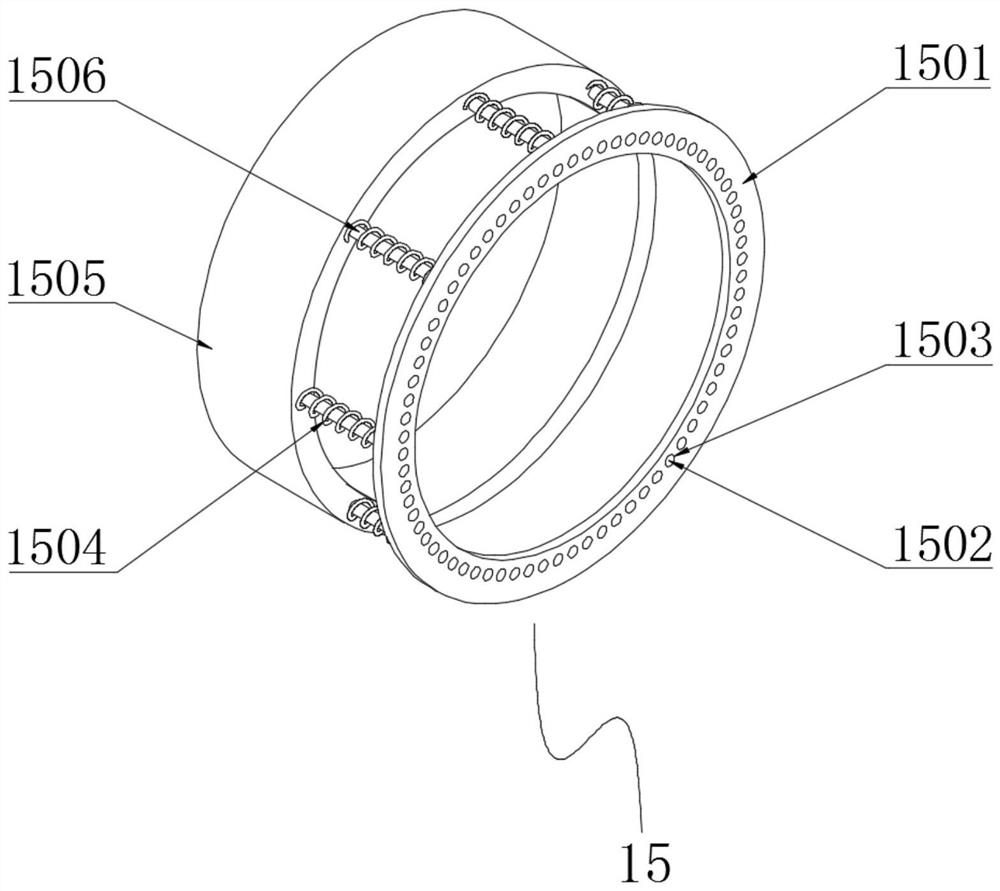

[0049] Embodiment 1: as Figure 1-8 As shown, the present invention provides a technical solution, an automatic measurement system for tap water detection, including a connecting pipeline 1, a protective cover 2 is welded on the outer surface of the connecting pipeline 1, and a wire hole 3 is opened on the top of the protective cover 2 , both ends of the connecting pipeline 1 are equipped with connecting flanges 8, and the outer surface of the connecting pipeline 1 is equidistantly connected with an adjusting assembly 9, and the adjusting assembly 9 includes an adjusting ring 901, a first positioning hole 902, a connecting block 903 and a mounting screw. hole 904;

[0050] The outer surface of the connecting pipeline 1 is equidistantly rotated and connected with an adjusting ring 901. The annular end surface of the adjusting ring 901 is equidistantly surrounded by a first positioning hole 902. The outer surface of the adjusting ring 901 is welded with a connecting block 903. T...

Embodiment 2

[0061] Embodiment 2: as Figure 1-10 As shown, the present invention provides a technical solution, an automatic measurement system for tap water detection, including a connecting pipeline 1, a protective cover 2 is welded on the outer surface of the connecting pipeline 1, and a wire hole 3 is opened on the top of the protective cover 2 , both ends of the connecting pipeline 1 are equipped with connecting flanges 8, and the outer surface of the connecting pipeline 1 is equidistantly connected with an adjusting assembly 9, and the adjusting assembly 9 includes an adjusting ring 901, a first positioning hole 902, a connecting block 903 and a mounting screw. hole 904;

[0062] The outer surface of the connecting pipeline 1 is equidistantly rotated and connected with an adjusting ring 901. The annular end surface of the adjusting ring 901 is equidistantly surrounded by a first positioning hole 902. The outer surface of the adjusting ring 901 is welded with a connecting block 903. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com