Preparation method of PdAuAg hollow nanosheet electrocatalyst

An electrocatalyst and nanosheet technology, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of complex preparation process, and achieve the effects of low preparation cost, high yield, and uniform sheet thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

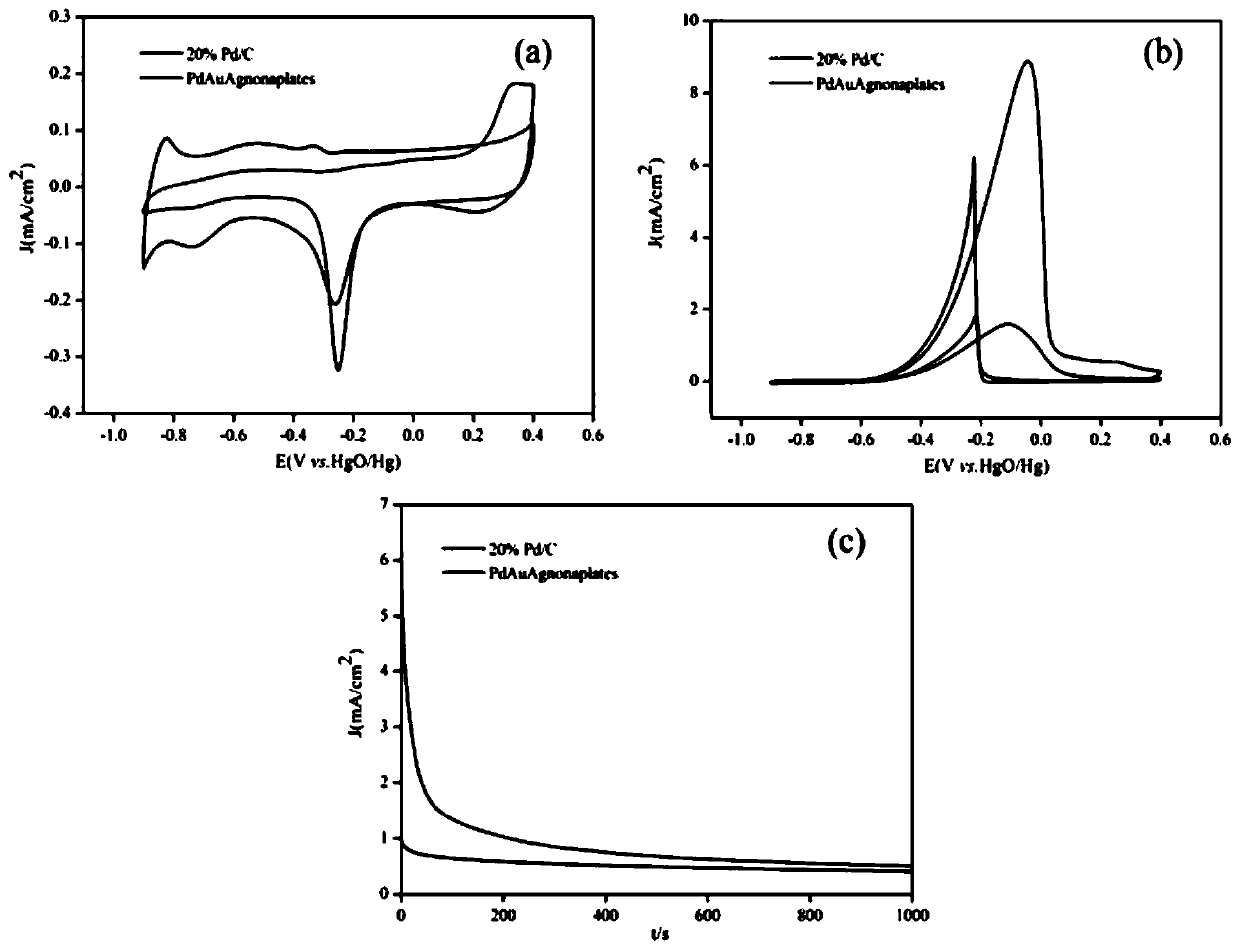

Examples

Embodiment 1

[0028] A preparation method of PdAuAg hollow nanosheet electrocatalyst, comprising the steps of:

[0029] (1) Prepare AgNO with a concentration of 63mM 3 (as a silver source) DMF (N, N-dimethylformamide) solution and a concentration of 0.63M PVP (polyvinylpyrrolidone, as a covering agent) DMF solution;

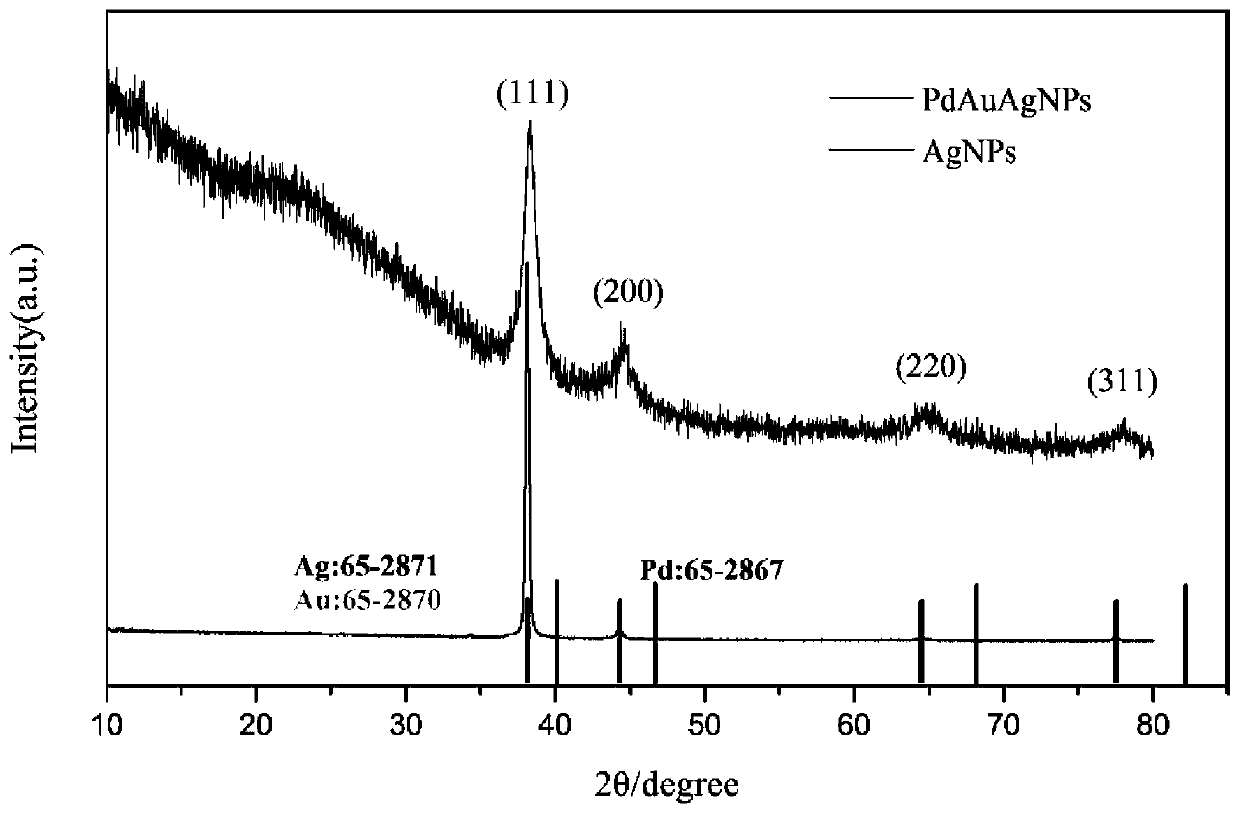

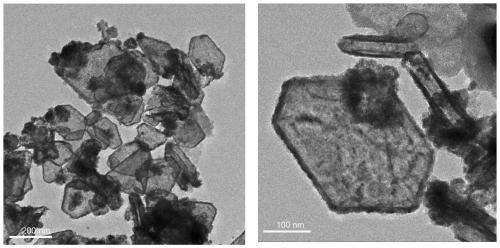

[0030] (2) In a 40mL reactor, add 10mL AgNO 3 Slowly add 5mL of DMF solution of PVP to the DMF solution of PVP, continue to stir for 25min to obtain a yellow-brown solution, then move the above reaction kettle into an oven, react at 160°C for 4h, cool to room temperature, and obtain a brown-gray solution, namely silver nanosheet solution (Such as figure 1 shown);

[0031] (3) Transfer half of the above brown-gray solution to a 250mL round bottom flask, dilute with 50mL deionized water, and stir at 10°C for 30min;

[0032] (4) Slowly add 100mL of HAuCl with a concentration of 0.34mM to the material obtained in step (3) at a temperature of 10°C 4 solution, the dropwise addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com