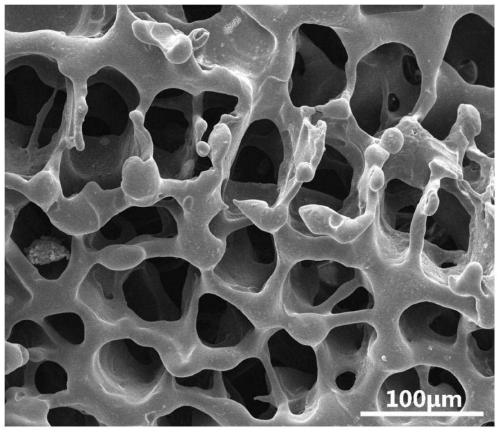

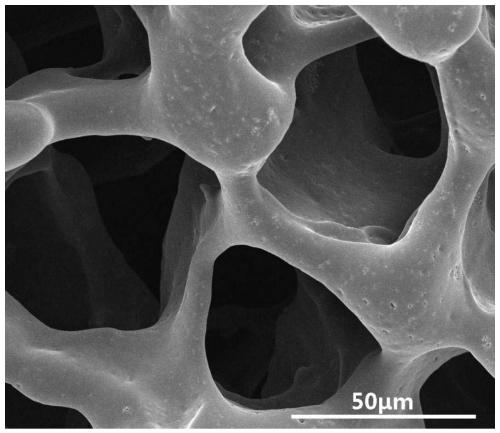

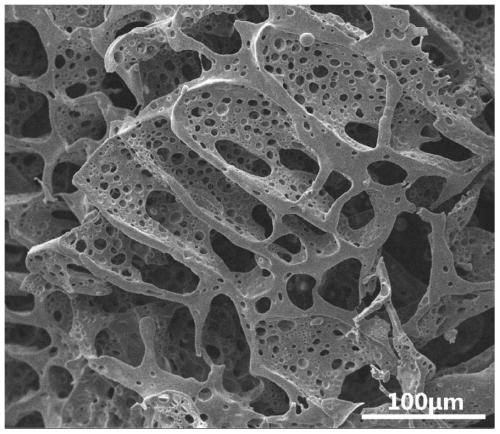

Hierarchical-pore-containing bioactive glass/polylactic acid-glycolic acid copolymer composite scaffold and preparation method thereof

A technology of bioactive glass and glycolic acid, which is applied in the field of preparation of biomedical materials, achieves the effects of stable quality, good osteoinductive ability, and favorable infiltration of body fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A bioactive glass / polylactic-co-glycolic acid (PLGA) composite scaffold containing a hierarchical pore structure, the preparation method of which is as follows:

[0036] (1) Preparation steps of bioactive glass powder:

[0037] First add 40 g of dodecylamine (DDA) to a mixed solution of 250 mL of deionized water and 800 mL of absolute ethanol, and then place it in a constant temperature water bath at 40°C for magnetic stirring until the dodecylamine is completely dissolved; Add 217.34 mL tetraethyl orthosilicate to the pump at a speed of 0.5 mL / min. During this process, due to the gradual formation of the Si network, the solution becomes turbid and becomes milky white; then add 22.02 mL triethyl phosphate at a speed of 0.5 mL / min with a syringe pump Then, dissolve 137.47 g of calcium nitrate tetrahydrate in 200 mL of deionized water, slowly add to the reaction solution, continue to stir for 3 h, and age at room temperature for 24 h; finally, centrifuge the glass sol to ...

Embodiment 2

[0041]A bioactive glass / polylactic-co-glycolic acid (PLGA) composite scaffold containing a hierarchical pore structure, the preparation method of which is as follows:

[0042] (1) Preparation steps of bioactive glass powder:

[0043] First add 4 g of dodecylamine (DDA) into a mixed solution of 25 mL of deionized water and 80 mL of absolute ethanol, and then place it in a constant temperature water bath at 40°C for magnetic stirring until the dodecylamine is completely dissolved; Add 21.73 mL tetraethyl orthosilicate to the pump at a speed of 0.5 mL / min. During this process, due to the gradual formation of the Si network, the solution becomes turbid and becomes milky white; then add 2.2 mL triethyl phosphate at a speed of 0.5 mL / min with a syringe pump. ester; then dissolve 13.75 g calcium nitrate tetrahydrate in 200 mL deionized water, slowly add into the reaction solution, continue to stir for 3 h, and age at room temperature for 24 h; finally, centrifuge the glass sol to obt...

Embodiment 3

[0047] A bioactive glass / polylactic-co-glycolic acid (PLGA) composite scaffold containing a hierarchical pore structure, the preparation method of which is as follows:

[0048] (1) Preparation steps of bioactive glass powder:

[0049] First add 8 g of dodecylamine (DDA) to a mixed solution of 50 mL of deionized water and 160 mL of absolute ethanol, and then place it in a constant temperature water bath at 40°C for magnetic stirring until the dodecylamine is completely dissolved; Add 43.46 mL tetraethyl orthosilicate to the pump at a speed of 0.5 mL / min. During this process, due to the gradual formation of the Si network, the solution becomes turbid and becomes milky white; then add 4.4 mL triethyl phosphate at a speed of 0.5 mL / min with a syringe pump. ester; then dissolve 27.48 g of calcium nitrate tetrahydrate in 200 mL of deionized water, slowly add to the reaction solution, continue to stir for 3 h, and age at room temperature for 24 h; finally, centrifuge the glass sol to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap