Low-temperature cured epoxy resin paint and preparation method thereof

A technology for curing epoxy resin and epoxy resin, which is applied in the field of low-temperature curing epoxy resin coating, low-temperature curing epoxy resin coating and its preparation, and can solve problems such as difficult drying of paint film, unsatisfactory drying effect, and shortening of drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

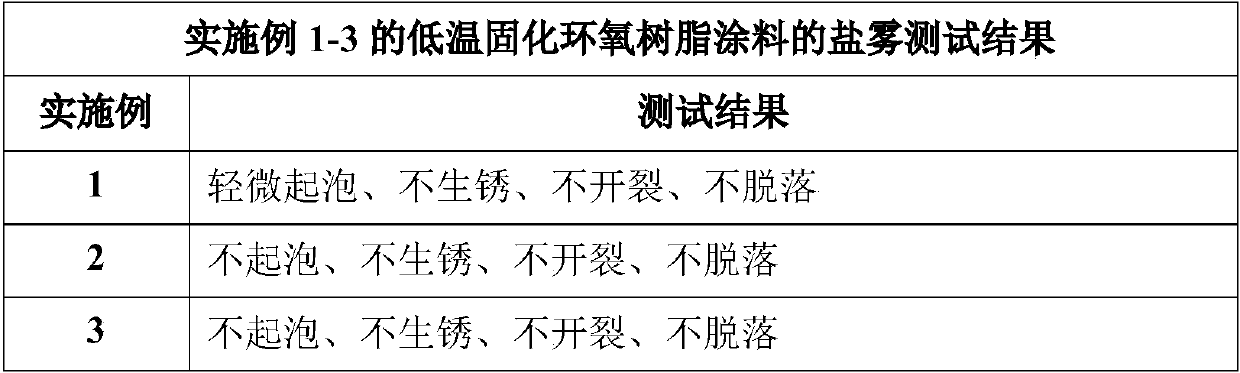

Examples

Embodiment 1

[0026] A low-temperature curing epoxy resin coating mainly consists of the following raw materials in parts by weight:

[0027] 80 parts of epoxy resin, 5 parts of di-n-butylamine, 30 parts of butyl acetate and 30 parts of hydroxyl-NCO curing agent.

[0028] A preparation method for low-temperature curing epoxy resin coating, comprising the following steps:

[0029] (1) Butyl acetate heating: raise the temperature of butyl acetate to 80°C;

[0030] (2) Epoxy resin dissolves: Epoxy resin is added in the butyl acetate that heats up through step (1), and carry out stirring and dissolving to obtain epoxy resin solution;

[0031] (3) Adding di-n-butylamine and curing agent: adding di-n-butylamine and hydroxyl-NCO curing agent dropwise to the epoxy resin solution of step (2) at 80°C;

[0032] (4) heat preservation: after completing the dropwise addition of step (3), heat preservation for 2 hours to obtain a finished product.

Embodiment 2

[0034] A low-temperature curing epoxy resin coating mainly consists of the following raw materials in parts by weight:

[0035] 100 parts of epoxy resin, 20 parts of di-n-butylamine, 50 parts of butyl acetate and 50 parts of hydroxyl-NCO curing agent.

[0036] A preparation method for low-temperature curing epoxy resin coating, comprising the following steps:

[0037] (1) Butyl acetate heating: raise the temperature of butyl acetate to 80°C;

[0038] (2) Epoxy resin dissolves: Epoxy resin is added in the butyl acetate that heats up through step (1), and carry out stirring and dissolving to obtain epoxy resin solution;

[0039] (3) Adding di-n-butylamine and curing agent: adding di-n-butylamine and hydroxyl-NCO curing agent dropwise to the epoxy resin solution of step (2) at 80°C;

[0040] (4) heat preservation: after completing the dropwise addition of step (3), heat preservation for 2 hours to obtain a finished product.

Embodiment 3

[0042] A low-temperature curing epoxy resin coating mainly consists of the following raw materials in parts by weight:

[0043] 120 parts of epoxy resin, 30 parts of di-n-butylamine, 70 parts of butyl acetate and 70 parts of hydroxyl-NCO curing agent.

[0044] A preparation method for low-temperature curing epoxy resin coating, comprising the following steps:

[0045] (1) Butyl acetate heating: raise the temperature of butyl acetate to 80°C;

[0046] (2) Epoxy resin dissolves: Epoxy resin is added in the butyl acetate that heats up through step (1), and carry out stirring and dissolving to obtain epoxy resin solution;

[0047] (3) Adding di-n-butylamine and curing agent: adding di-n-butylamine and hydroxyl-NCO curing agent dropwise to the epoxy resin solution of step (2) at 80°C;

[0048] (4) heat preservation: after completing the dropwise addition of step (3), heat preservation for 2 hours to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com