Filtering device capable of achieving automatic cleaning and clothing treating equipment

A technology for clothing processing equipment and filtering devices, which is applied to washing devices, household dryers, cleaning methods and utensils, etc., can solve problems such as condenser blockage, water tank pollution, limited condensed water, etc. Simple and efficient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

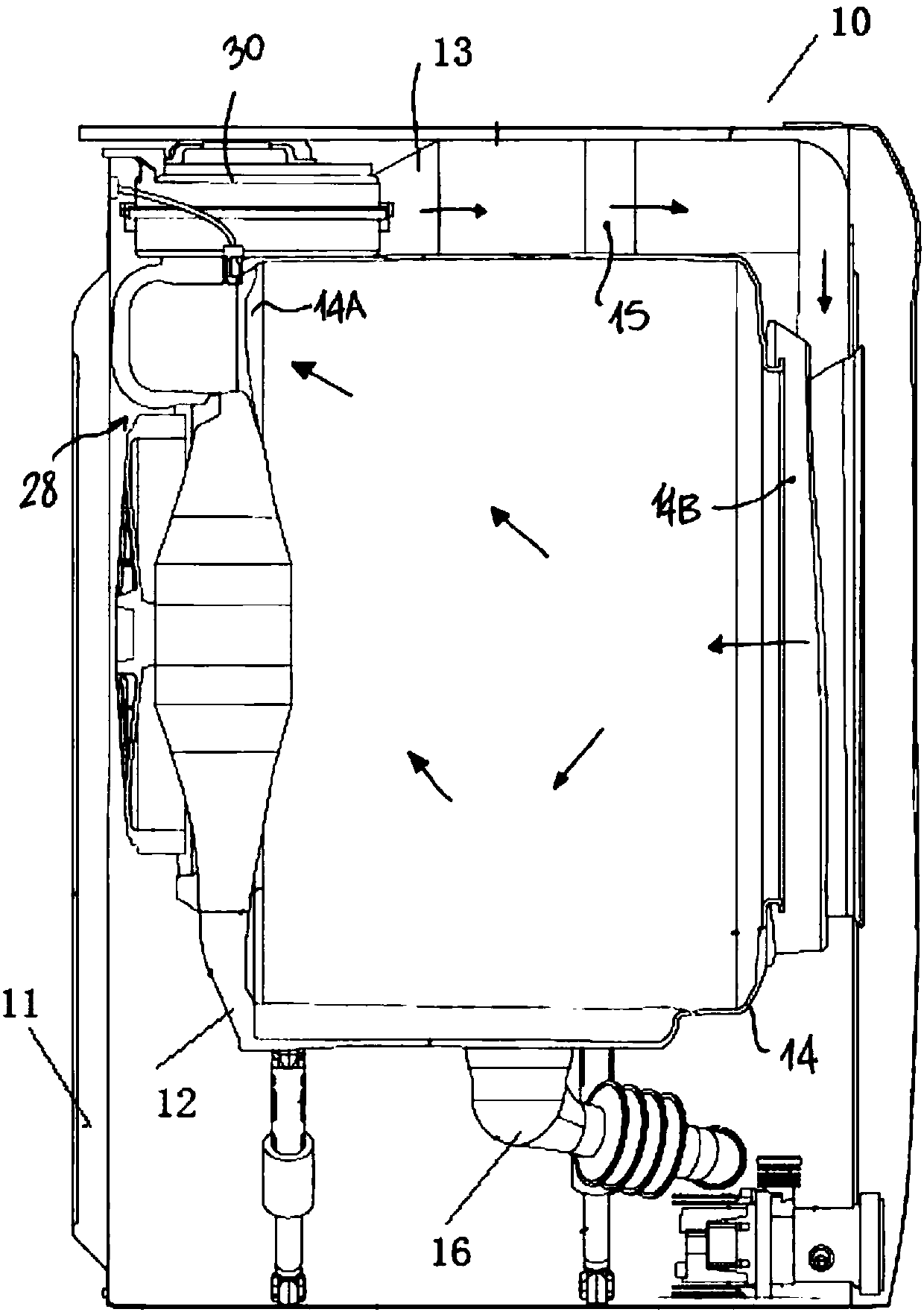

[0051] like Figure 1-7 As shown, the present embodiment provides a filter device 28 that can be cleaned automatically. The filter device 28 includes a tubular support structure 43, a filter structure and a cleaning structure. The inside of the tubular support structure 43 has a passage for gas circulation. 81. The filtering structure is inserted inwardly from the outer circumference of the tubular supporting structure 43 into the tubular supporting structure 43, so that the gas circulating in the channel 81 is filtered through the filtering structure, and the cleaning structure is arranged above the filtering structure, and is transported to the filtering structure The washing liquid flushes the filter structure.

[0052] The filter device 28 of this embodiment is assembled on the clothes treatment device 10 for drying the clothes at least once. The filter device 28 can be fixedly connected with the air circulation channel 13 of the clothes treatment device 10 as a separate p...

Embodiment 2

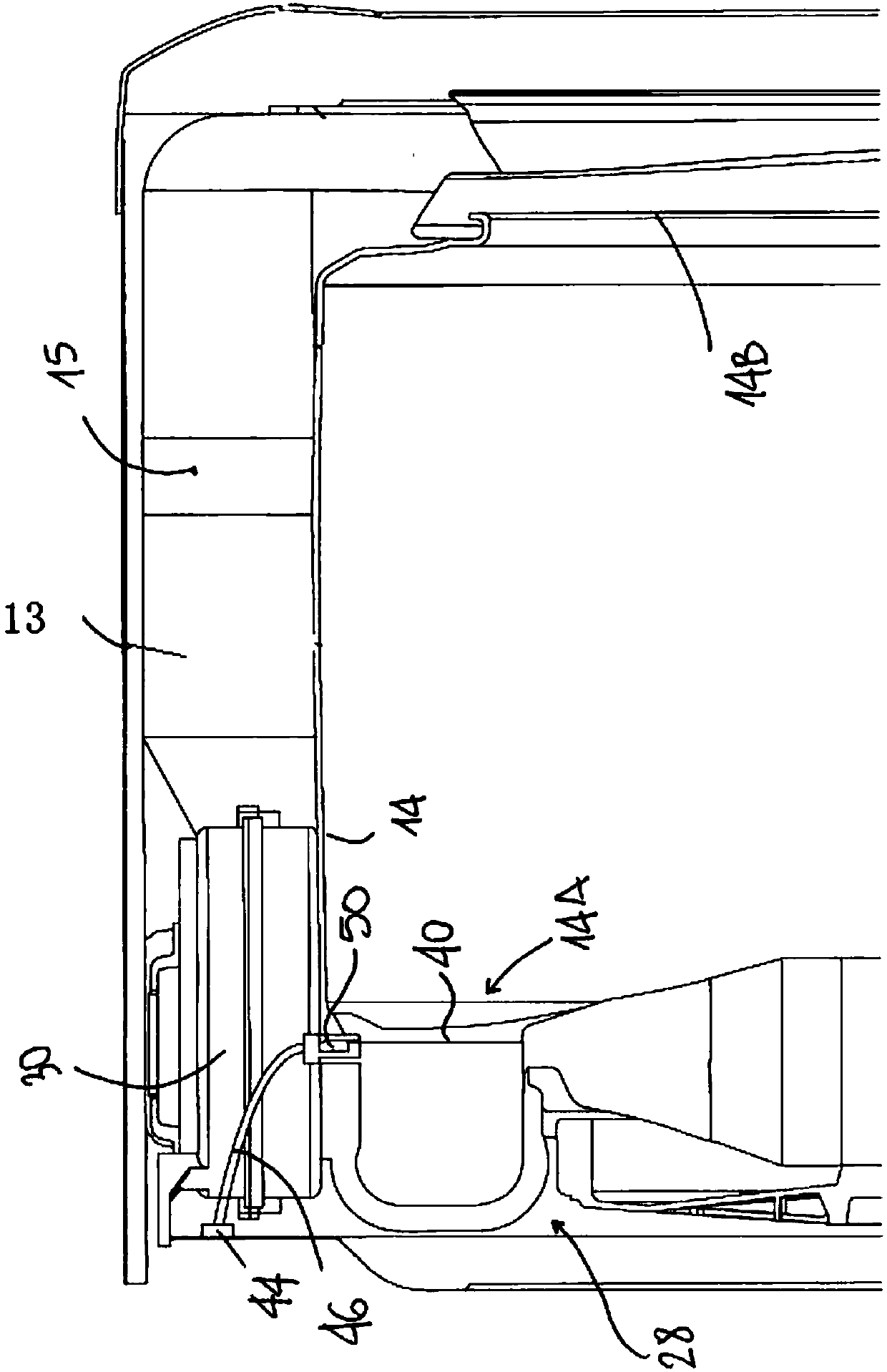

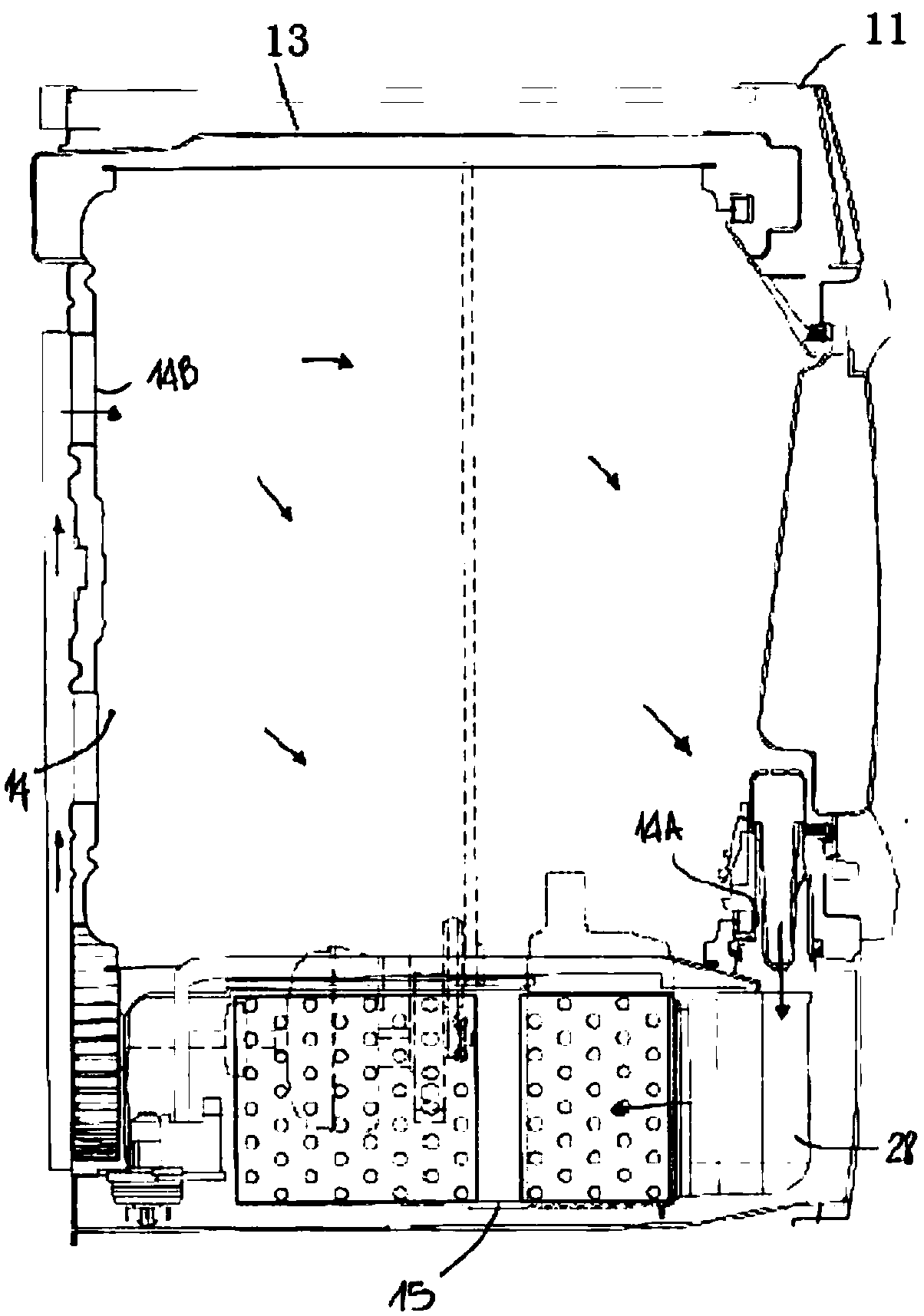

[0070] like Figure 4-7 As shown, this embodiment is a further limitation of Embodiment 1. The filter device 28 of this embodiment at least includes a first filter structure 40 and a second filter structure 60, both of which are respectively inserted into respective tubular support structures 43, and both The tubular support structure 43 is connected, the first filter structure 40 and the second filter structure 60 are arranged in parallel or at a certain angle, and the gas flows through the first filter structure 40 and the second filter structure 60 for filtration.

[0071] In order to enhance the filtering effect and prevent lint and lint from adhering to the condenser 30 with the airflow, at least two filtering structures are provided in this solution. The tubular support structures 43 of the first filter structure 40 and the second filter structure 60 can be directly fixed to each other, and the channels communicate with each other, or can be indirectly connected and fixe...

Embodiment 3

[0079] like Figure 4 As shown, the present embodiment is a further limitation of the second embodiment, the assembly support structure 80 is a horizontal linear pipeline, and the tubular support structures 43 of the first filter structure 40 and the second filter structure 60 are respectively arranged on the assembly support The two ends of the structure 80 are integrally formed or fixedly connected, and the filtering planes of the first filtering structure 40 and the second filtering structure 60 are arranged in parallel, and both are perpendicular to the central axis of the linear pipe.

[0080] During assembly, the first filter structure 40 is inserted into the first slot 83, the first cleaning structure 50 is fastened to the upper part of the first support frame 41, and then the body of the first cleaning structure 50, the first support frame 41 and the first insert The groove 83 is fixed by bolts. The second filter structure 60 is inserted into the second slot 84, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com