Well drilling self-excited vibration and stick-slip vibration simulation experiment device

A technology for simulating experimental device and self-excited vibration, applied in drilling equipment, drilling measurement, earthwork drilling, etc., can solve the problems of inaccuracy, directness, inability to simulate stick-slip vibration, etc., to achieve high monitoring accuracy and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

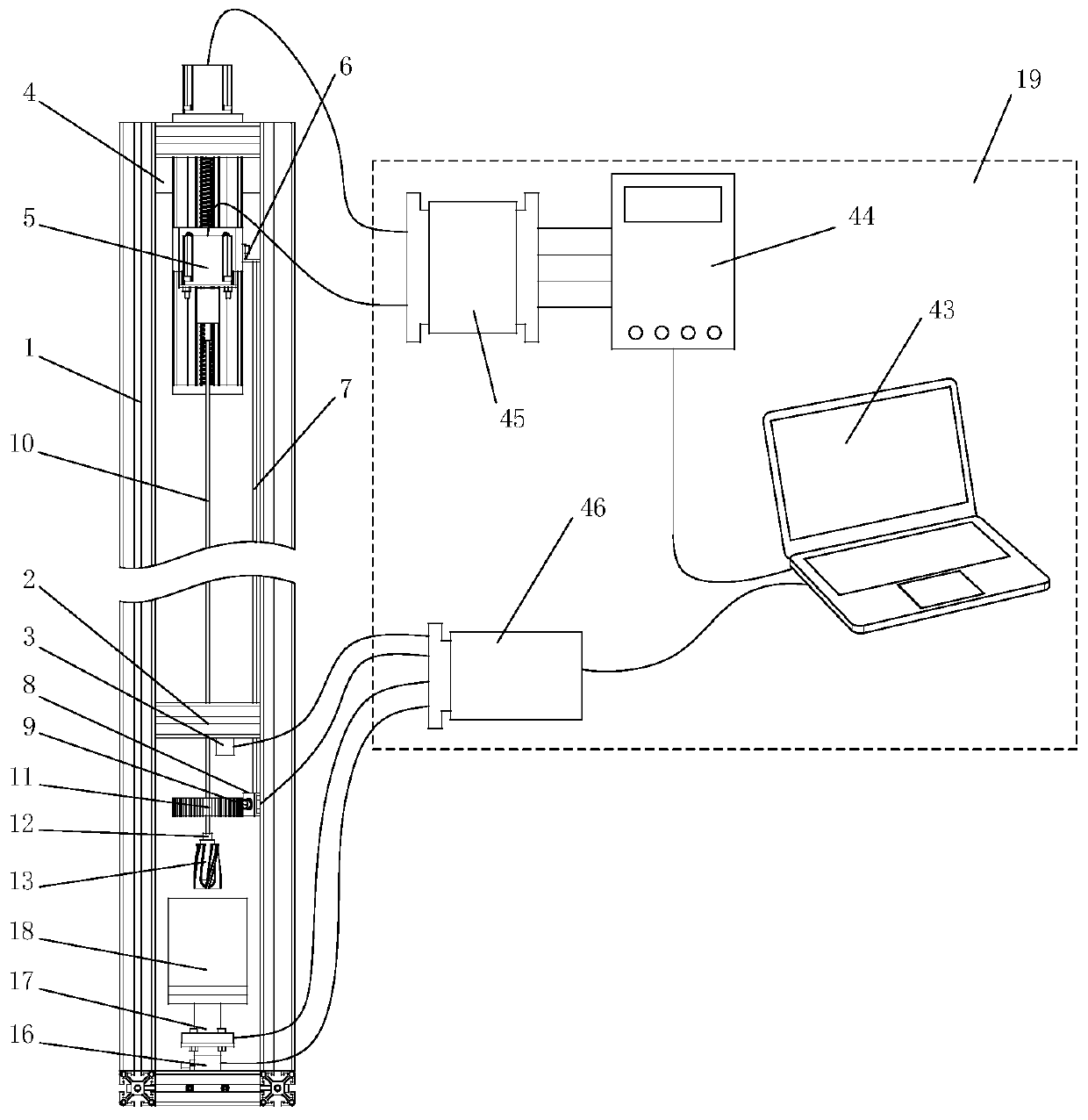

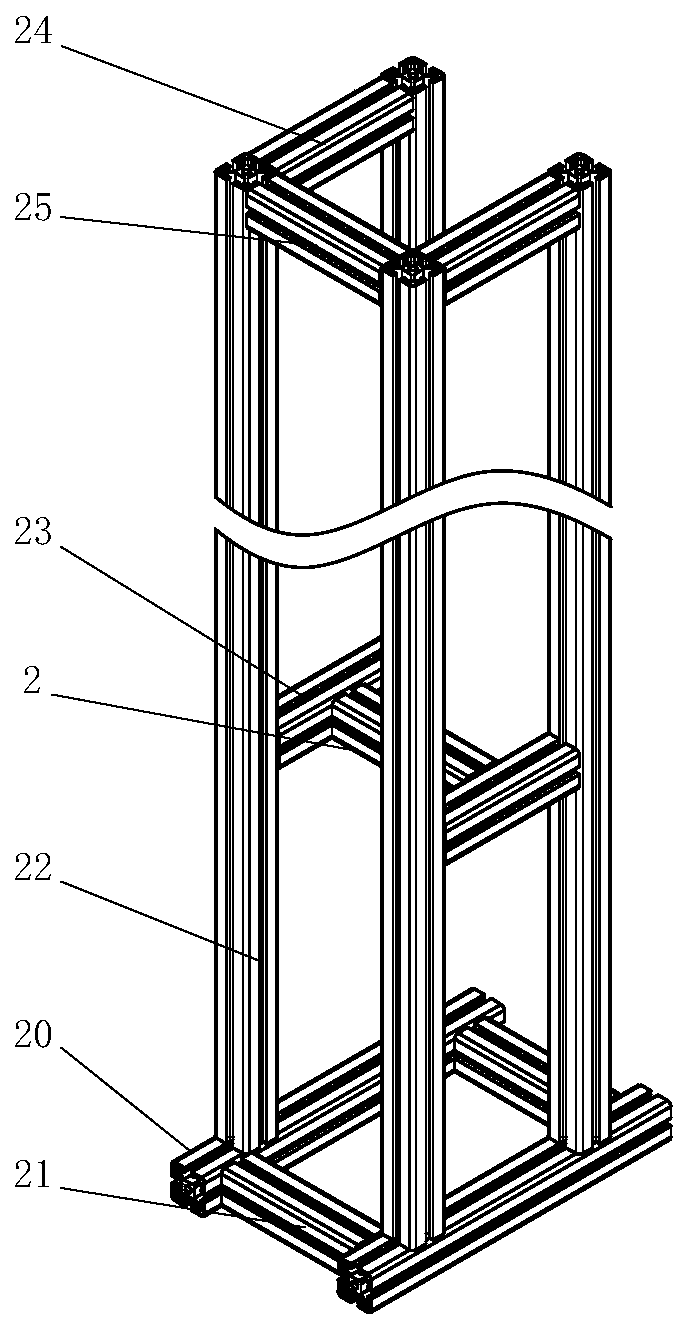

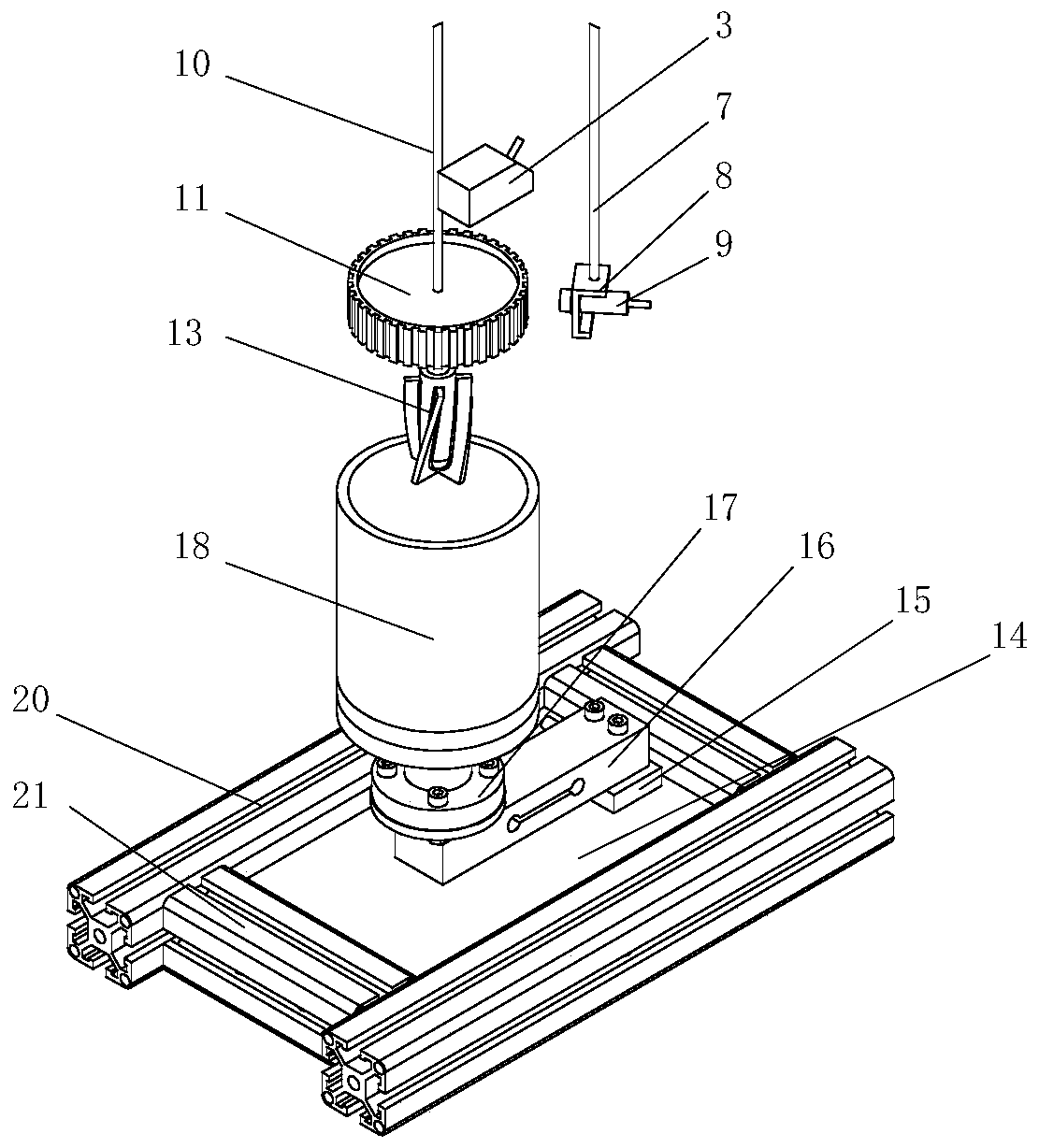

[0042] Such as Figure 1-7 As shown, a drilling self-excited vibration and stick-slip vibration simulation experiment device of the present invention includes: a frame assembly 1, a top drive assembly 5, a micro drill pipe 10, a micro drill bit 13, a simulated rock formation assembly 18, an optical code disc 11, Ultrasonic displacement sensor 3 , photoelectric sensor 9 , torque sensor 17 , pressure sensor 16 and data acquisition system 19 .

[0043] The top driving assembly 5 is installed on the top of the frame assembly 1 through the hanging plate 4 arranged on the upper rear side of the frame assembly 1 . The top drive assembly 5 is used to drive the micro drill rod 10 to move up and down and rotate. One end of the micro drill pipe 10 is connected to the top driving assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com