Wind turbine generator blade online monitoring system and work method thereof

A monitoring system and wind turbine technology, applied in the monitoring of wind turbines, wind turbines, engines, etc., can solve the problems of damaged blade structure, low blade strength, fatigue of blade adhesive materials, etc., to avoid fracture, ensure safe operation, Realize the effect of online monitoring and analysis function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0019] Example.

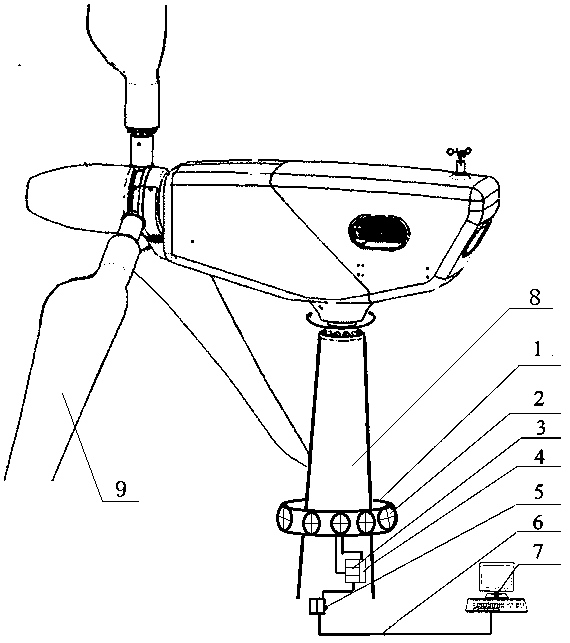

[0020] see figure 1 , an online monitoring system for wind turbine blades, comprising a laser sensor holder 1, a laser sensor 2, a data acquisition device 3, a sensor power supply output interface 4, a tower base optical fiber reserved interface 5, an optical fiber 6, and a data storage and analysis device 7; The laser sensor 2 is surrounded by the laser sensor holder 1 on the outer wall of the tower 8, and the height of the laser sensor 2 from the ground is higher than 0.5-2 meters from the height of the blade tip to the ground when the blade 9 is vertically downward; the data acquisition device 3 is connected to the laser sensor 2, and the data acquisition device 3 is connected to the tower base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com