Intelligent verification monitoring device for density relay, and gas supplementation and verification methods of device

A density relay and monitoring device technology, applied in the direction of circuit breaker testing, etc., can solve the problems of difficult disassembly and assembly, time urgency, and strong professional requirements, so as to eliminate manual operation false alarms, improve calibration work efficiency, Eliminate the effect of personal danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

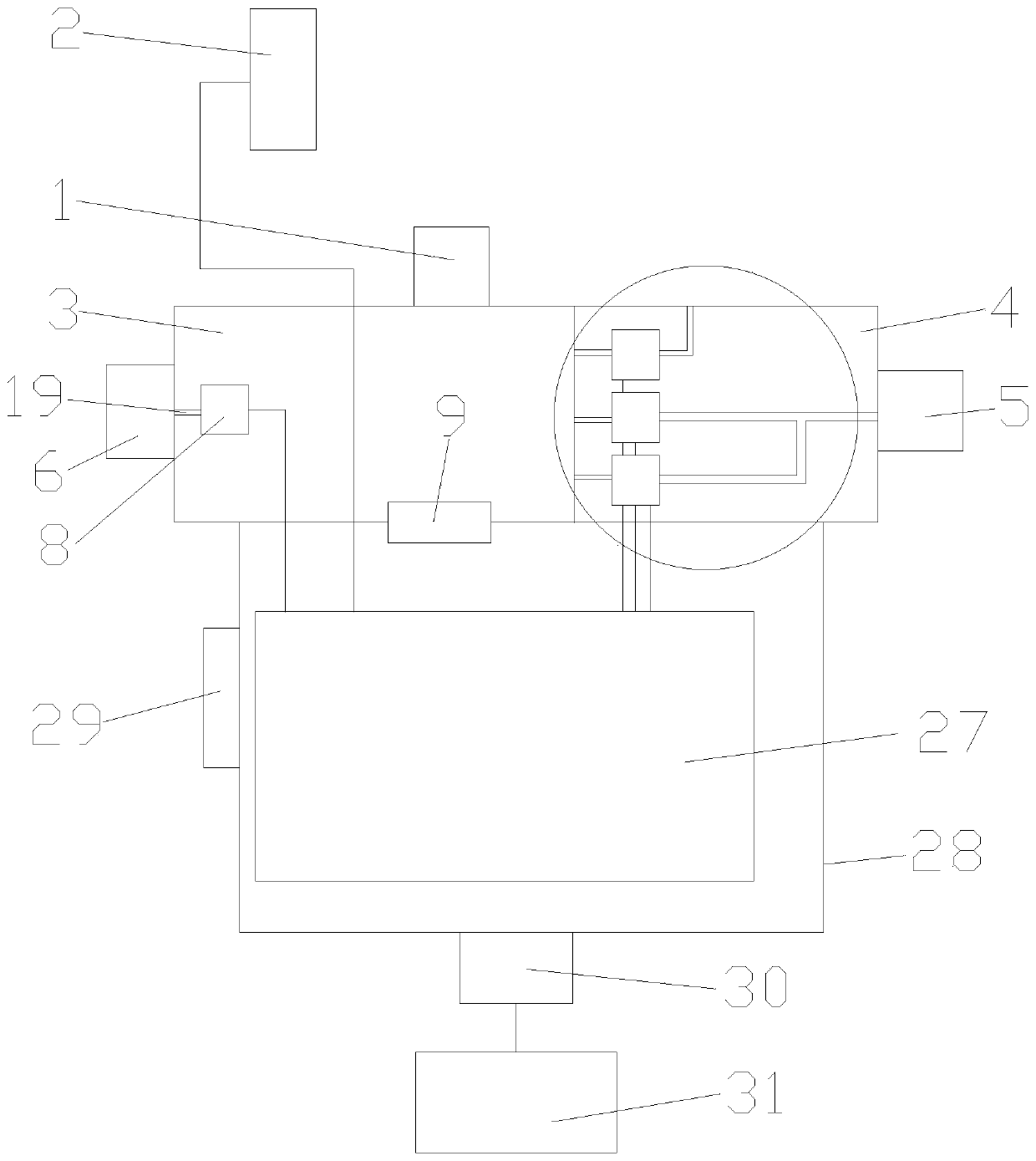

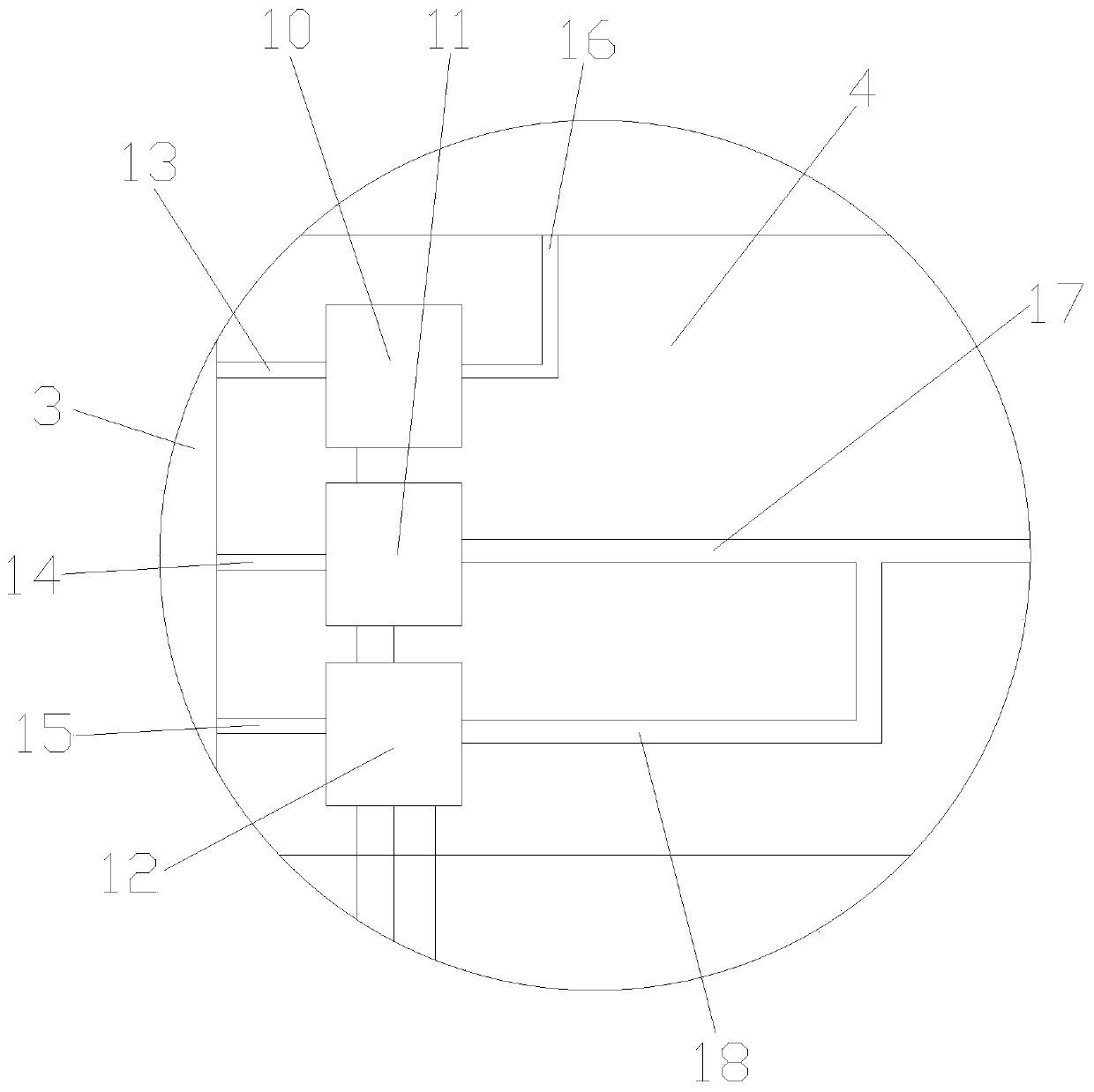

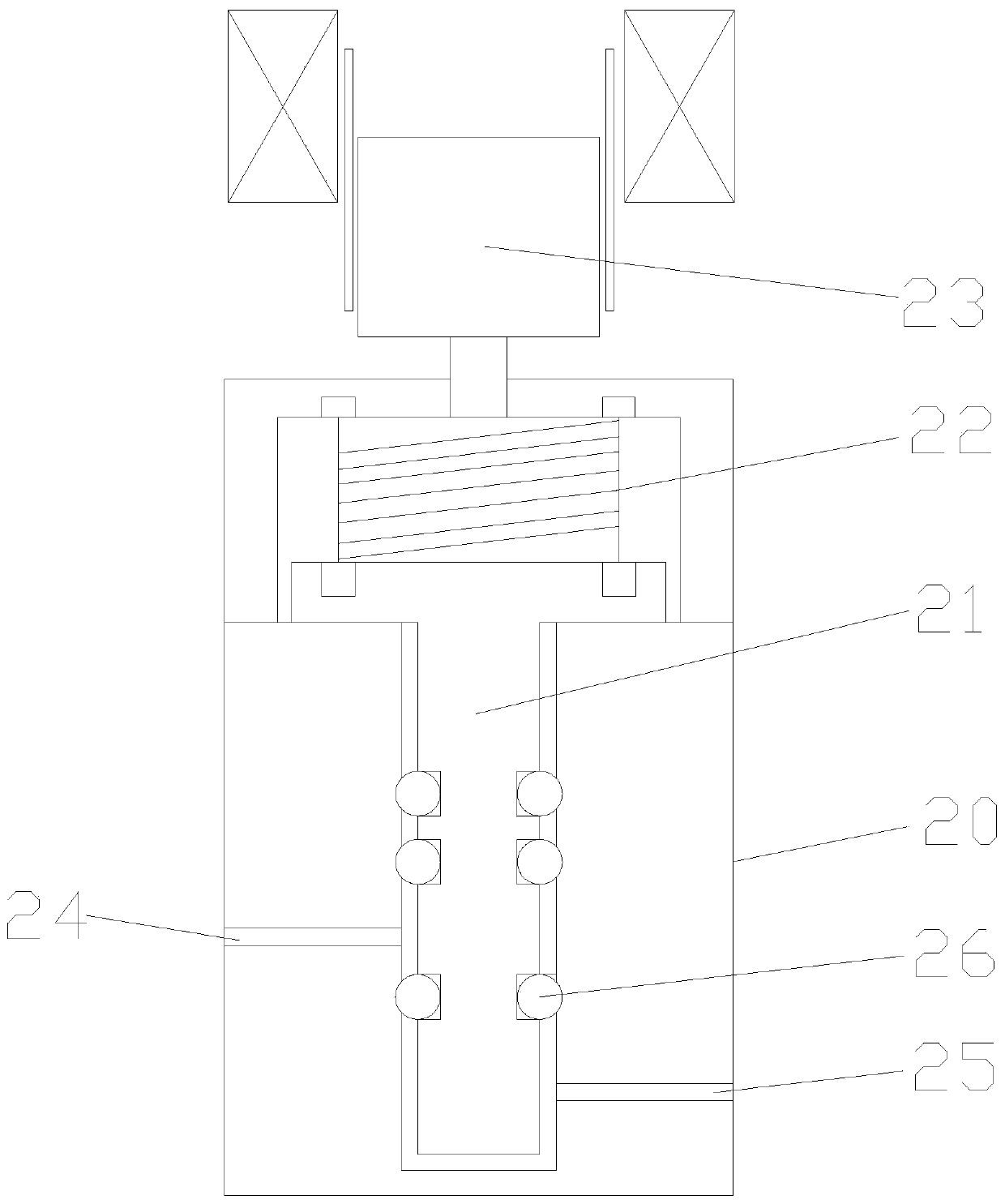

[0043] The present invention is described below in conjunction with accompanying drawing.

[0044] as attached Figure 1-5 The shown a kind of density relay intelligent verification and monitoring device of the present invention includes a mechanical module, a circuit module and a background module 31; the mechanical module is connected to the circuit module; the circuit module is connected to the background module 31 through a network; After the mechanical module and the background module 31 are connected through the circuit module, they can communicate normally.

[0045] In the above-mentioned density relay intelligent verification monitoring device, the mechanical module includes a density relay interface 1, a density relay electrical interface 2, a detection gas chamber 3, a working gas chamber 4, a switchgear butt joint 5 and an air supply joint 6; the density Both the relay interface 1 and the density relay electrical interface 2 are connected to the density relay 7; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com