Insulation treatment process for superconducting magnet wire-outlet end of Y-shaped tail end structure

A superconducting magnet and insulation treatment technology, which is applied in the direction of superconducting magnet/coil, magnetic object, coil manufacturing, etc., can solve the problem of no existing experience in the outlet end of superconducting magnets, etc., achieve simple structure, easy operation, and ensure insulation strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

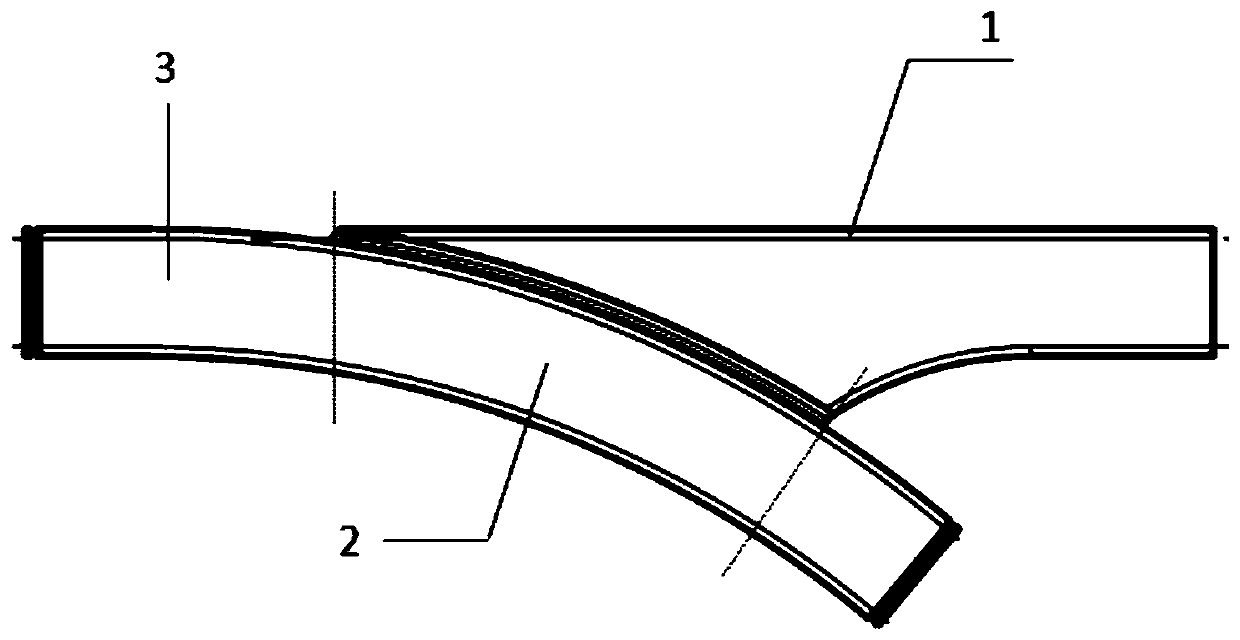

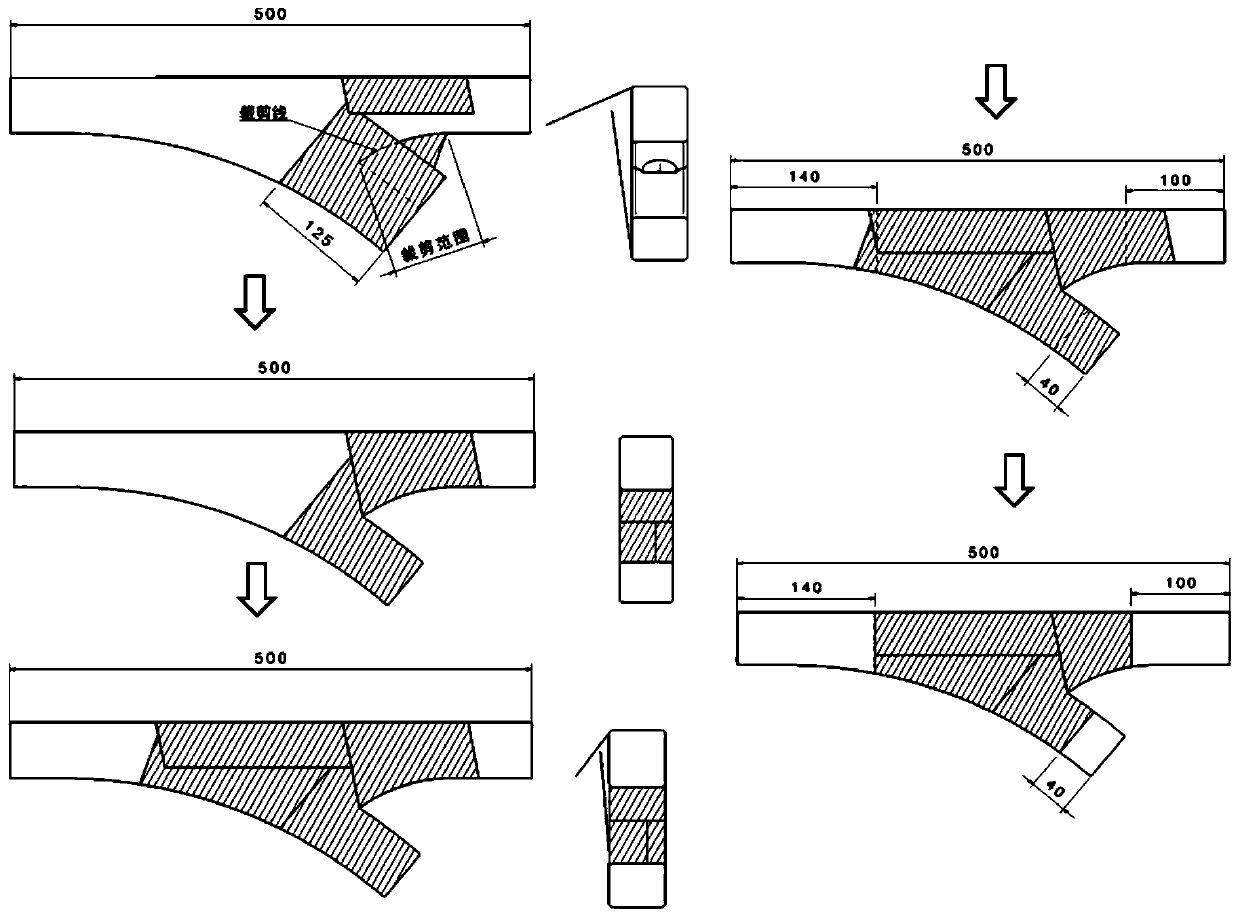

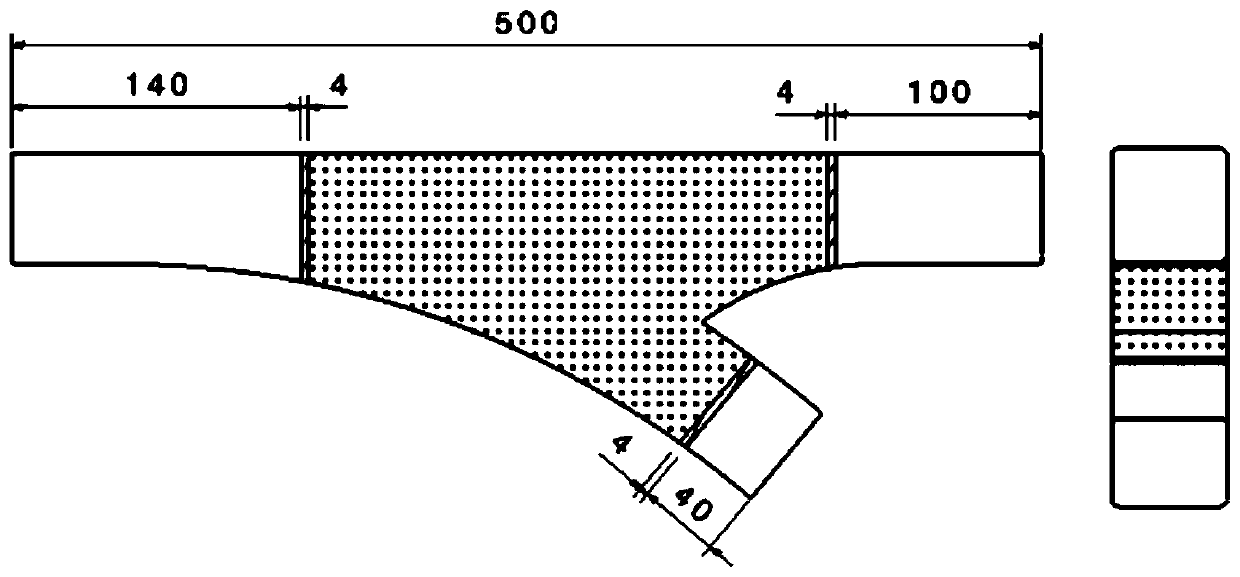

[0027] like Figure 1-Figure 6 As shown, an insulation treatment method for the outlet end of a superconducting magnet with a Y-shaped tail structure, the outlet end of the superconducting magnet includes a 1-superconductor and a 2-conductor end piece. One end of the side of the superconductor tail is connected to the side of the conductor tail piece by welding to form a Y-shaped structure. 2—The superconductor is used as a fork of the Y-shaped structure, and in the conductor end piece, the section from the connection of the 1—superconductor to the end of the conductor end piece is used as another fork of the Y-shaped structure. 3—The section from the superconductor connection to the other end of the conductor end piece is used as the root of the Y-shaped structure. It is characterized in that: comprising the following steps:

[0028] 1) First, wrap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com