Multifunctional mixer for powder paint

A powder coating, multifunctional technology, used in mixers, mixers with rotating containers, chemical instruments and methods, etc., can solve the problems of powder coating layering, reduced productivity, uneven heating, etc., to improve efficiency , Reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Here, it should be noted that the functions, methods, etc. involved in the present invention are only conventional adaptive applications of the prior art. Therefore, the improvement of the present invention to the prior art lies in the connection relationship between the hardware, rather than the functions and methods themselves. Improve. The description of the functions and methods in the present invention is to better illustrate the present invention so as to better understand the present invention.

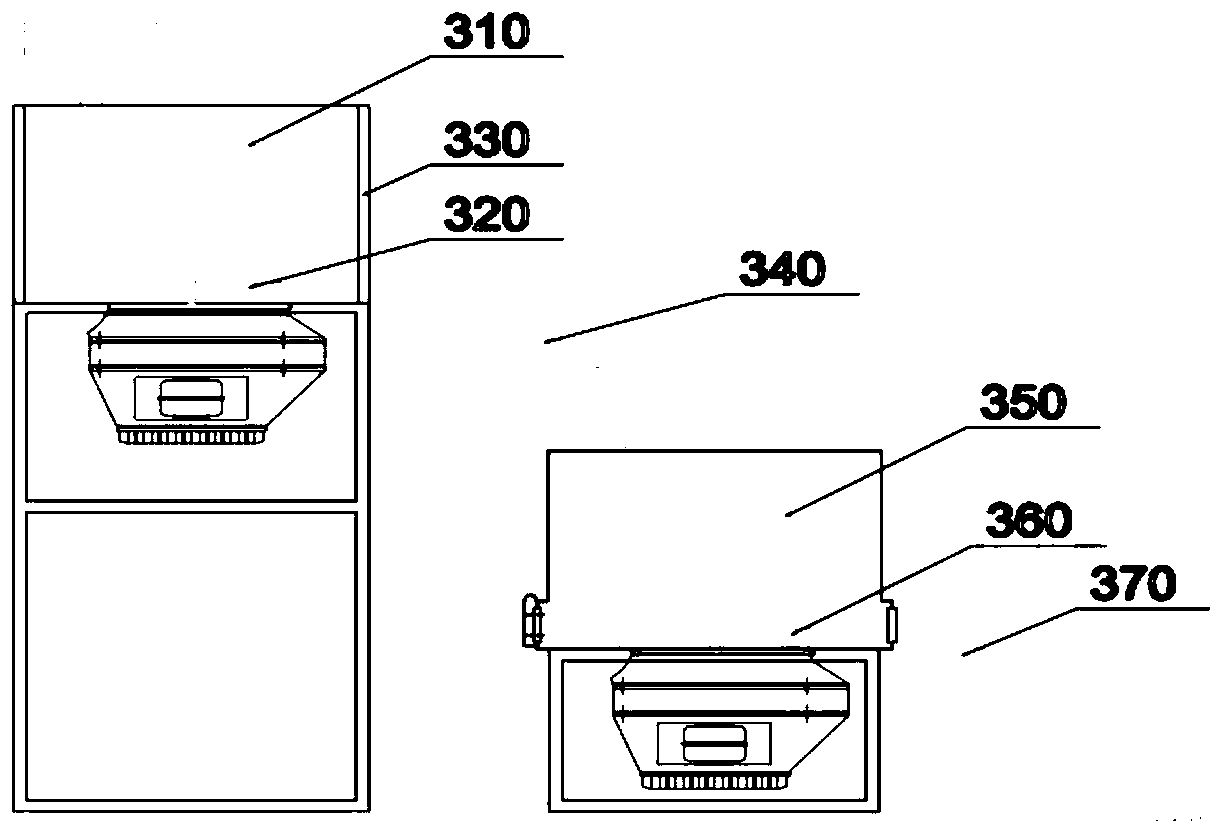

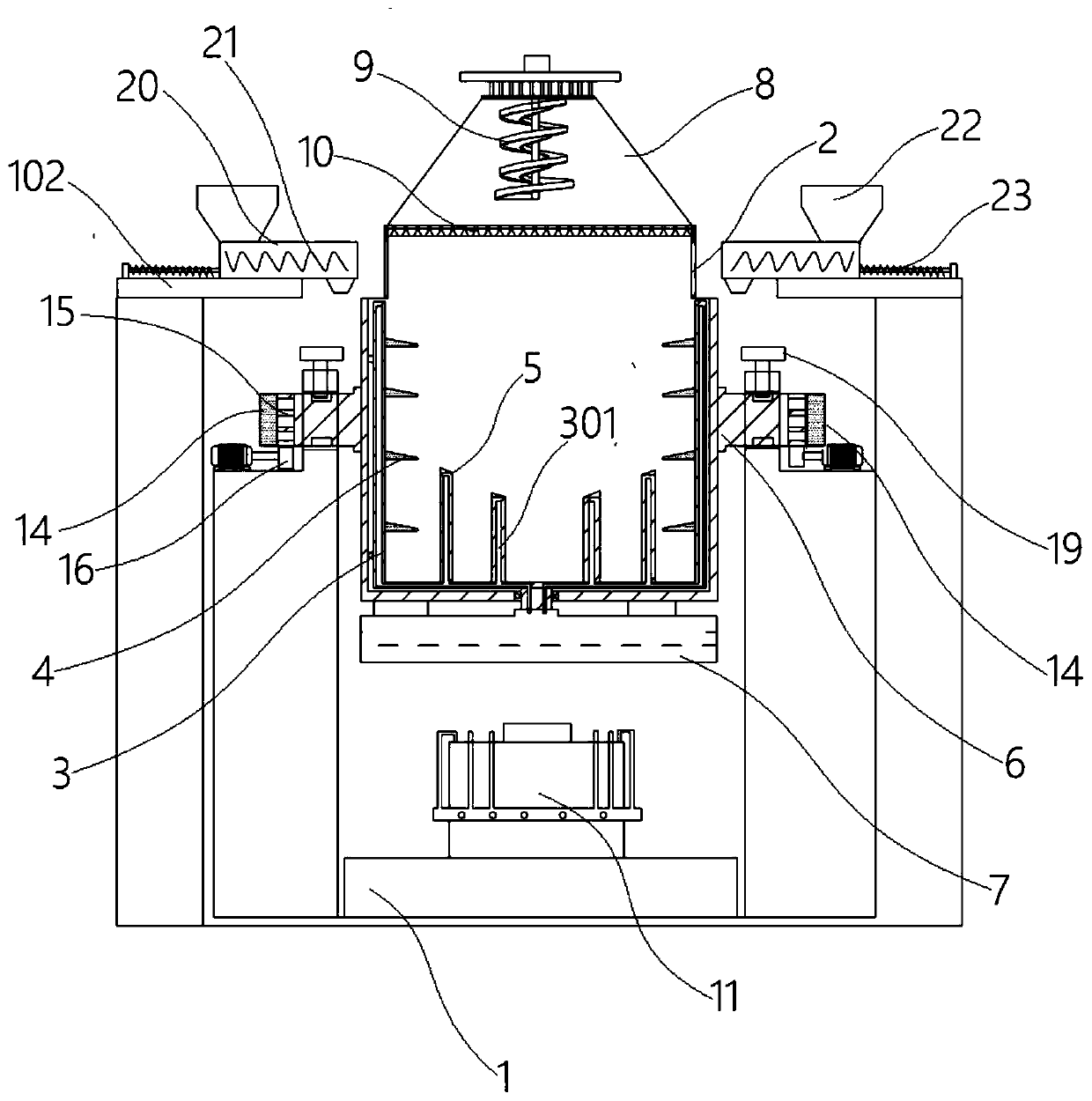

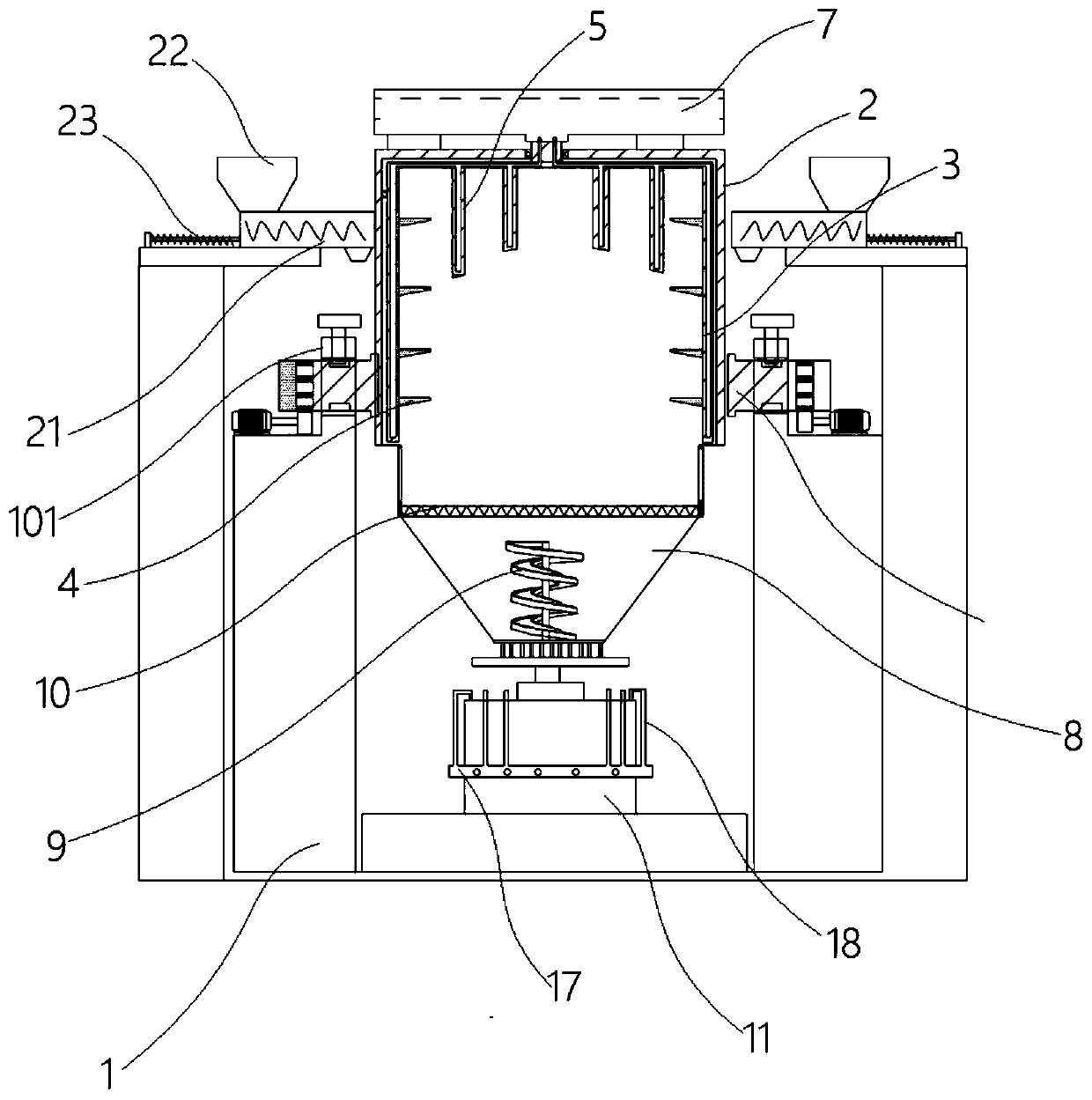

[0029] Please refer to Figure 2 to Figure 5 , figure 2 The stirring schematic diagram of the powder coating multifunctional mixer provided for an embodiment; image 3 A schematic diagram of the discharge of a multifunctional mixer for powder coatings provided by an embodiment; Figure 4 The schematic diagram of the pin wheel transmission of the multifunctional mixer for powder coating provided by an embodiment; Figure 5 It is a schematic diagram of the structure ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap