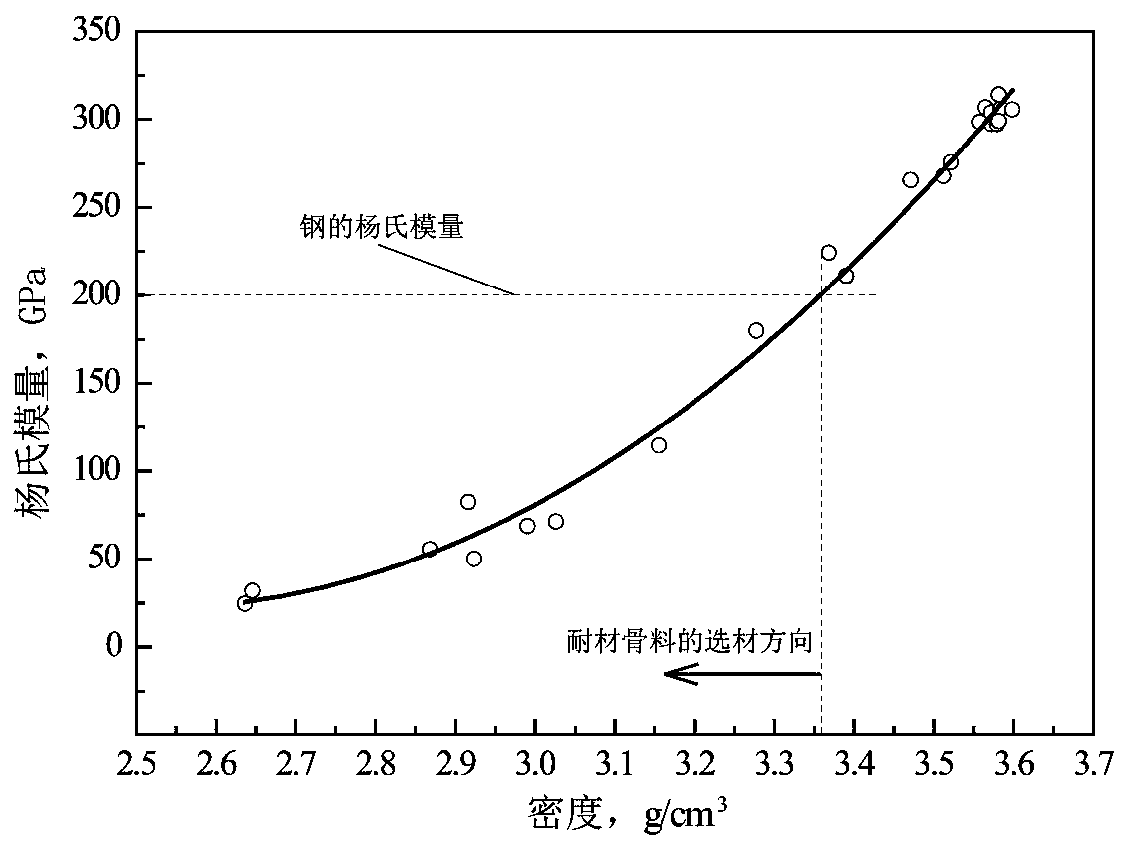

Low-Yang-modulus submersed nozzle lining material

A Young's modulus, immersion technology, used in casting melt containers, metal processing equipment, casting equipment, etc., can solve problems such as melting loss, peeling wire, drawing and breaking wire, etc., to reduce costs and reduce melting loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

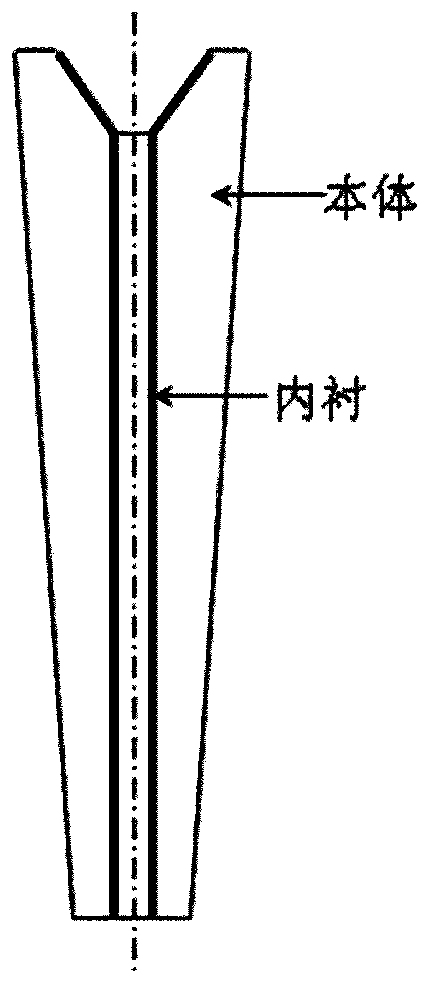

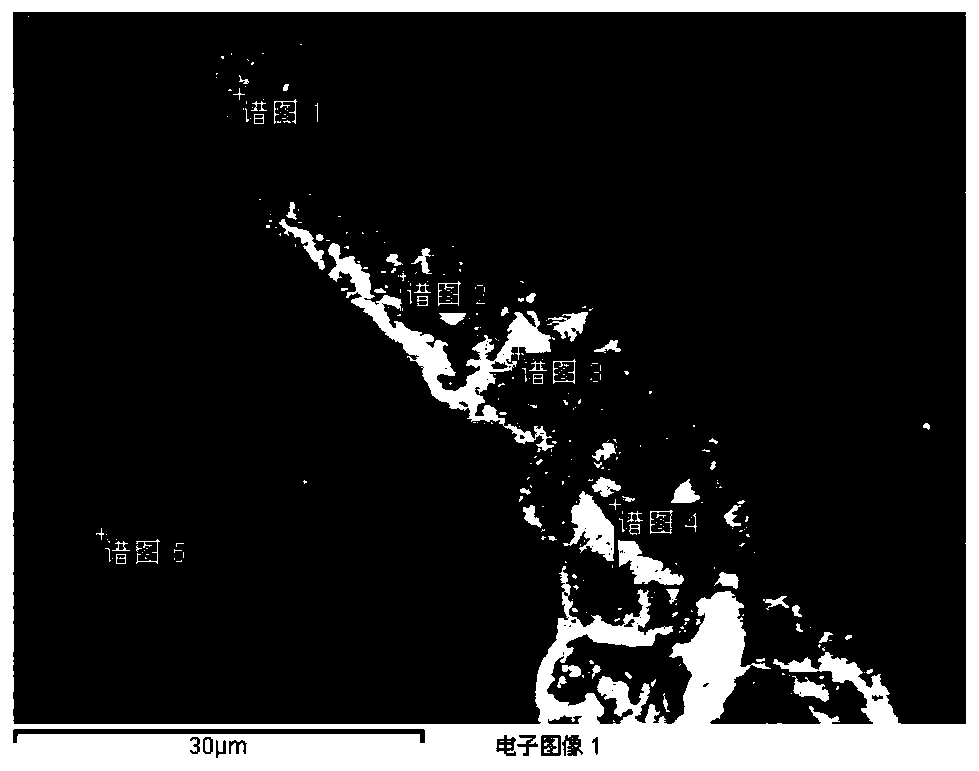

[0021] A submerged nozzle lining material with low Young's modulus, which is made by mixing raw materials in the following percentages by weight: 93% magnesium oxide, plus 7% phenolic resin as a binder. The particle size of magnesium oxide is 0.1mm-1.0mm, and the density of magnesium oxide particles is 3.13g / cm 3 , Lining thickness 5mm.

Embodiment 2

[0023] A submerged nozzle lining material with low Young's modulus, which is made by mixing raw materials according to the following weight percentage, 90% of magnesium oxide, plus 10% of phenolic resin as a binding agent. The particle size of magnesium oxide is 0.1mm-1.0mm, and the density of magnesium oxide particles is 3.0g / cm 3 , lining thickness 3mm.

Embodiment 3

[0025] A submerged nozzle lining material with low Young's modulus, which is made by mixing raw materials according to the following weight percentage, 95% of magnesium oxide, plus 5% of phenolic resin as a binder. The particle size of magnesium oxide is 0.1mm-1.0mm, and the density of magnesium oxide particles is 3.24g / cm 3 , Lining thickness 6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com