Spring feeding device, spring loading equipment and method thereof used for optical fiber connector assembling

A fiber optic connector and equipment technology, applied in the field of spring feeding device, can solve the problem that the spring is easy to get stuck at the connection between the transparent tube and the optical fiber core, affecting the performance and service life of the optical fiber connector, and the processing accuracy of the transparent tube and the optical fiber core is not enough and other problems, to achieve the effect of reasonable and ingenious structural design, shortening working hours and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

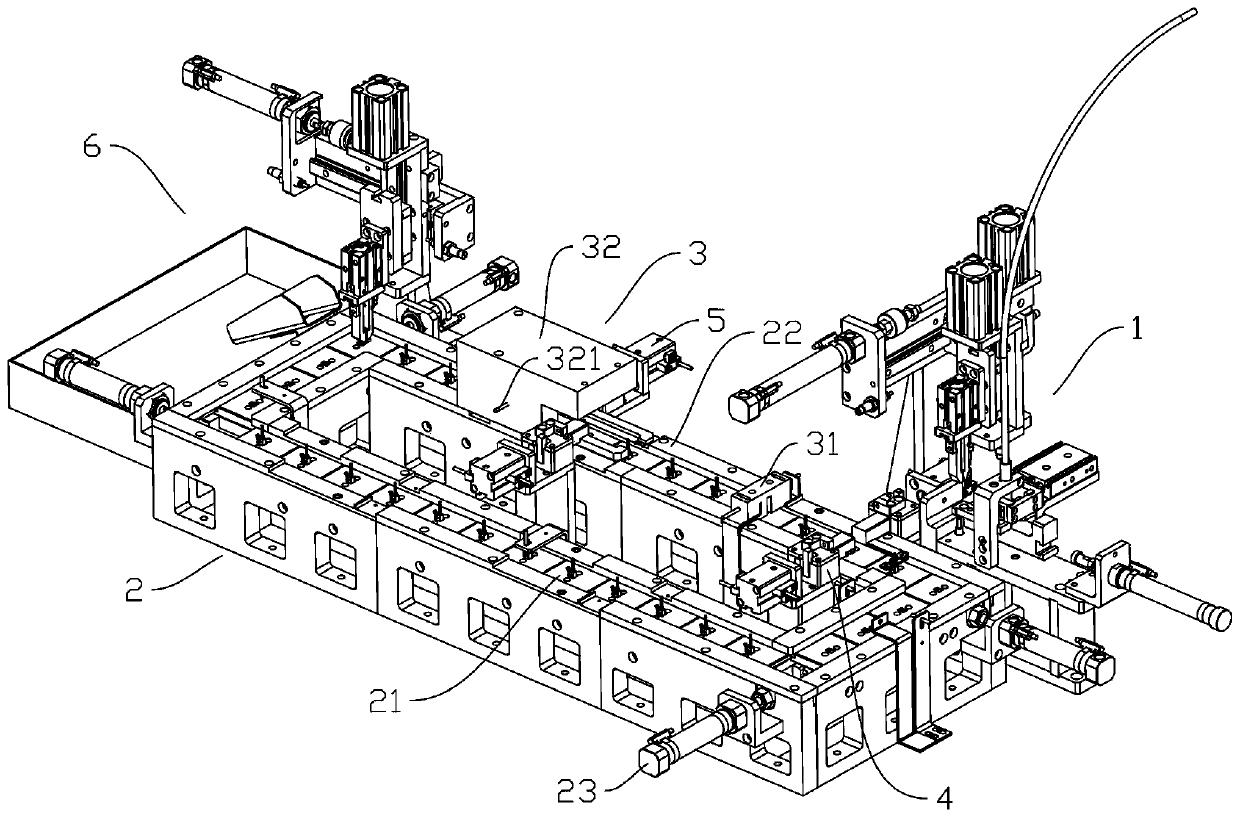

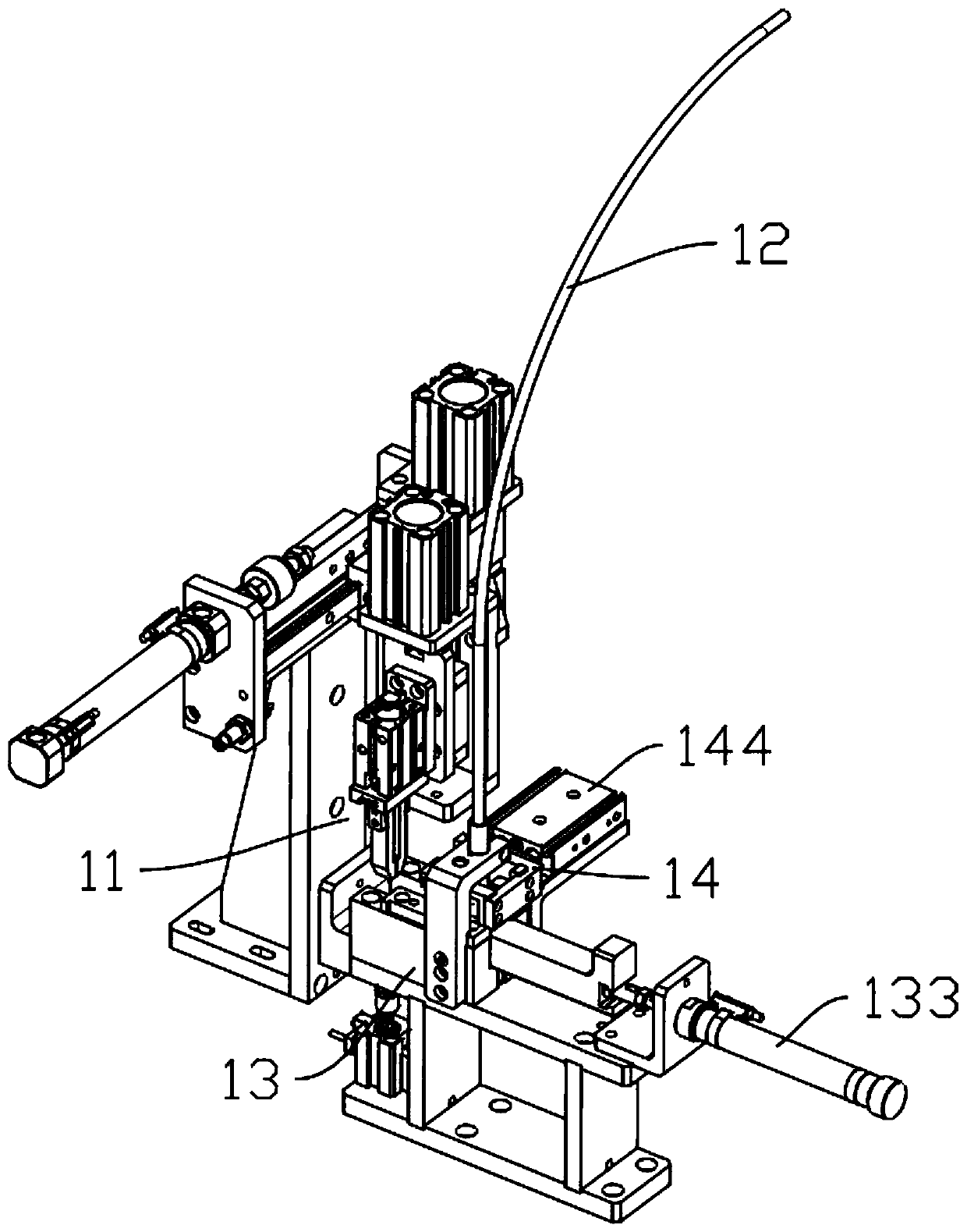

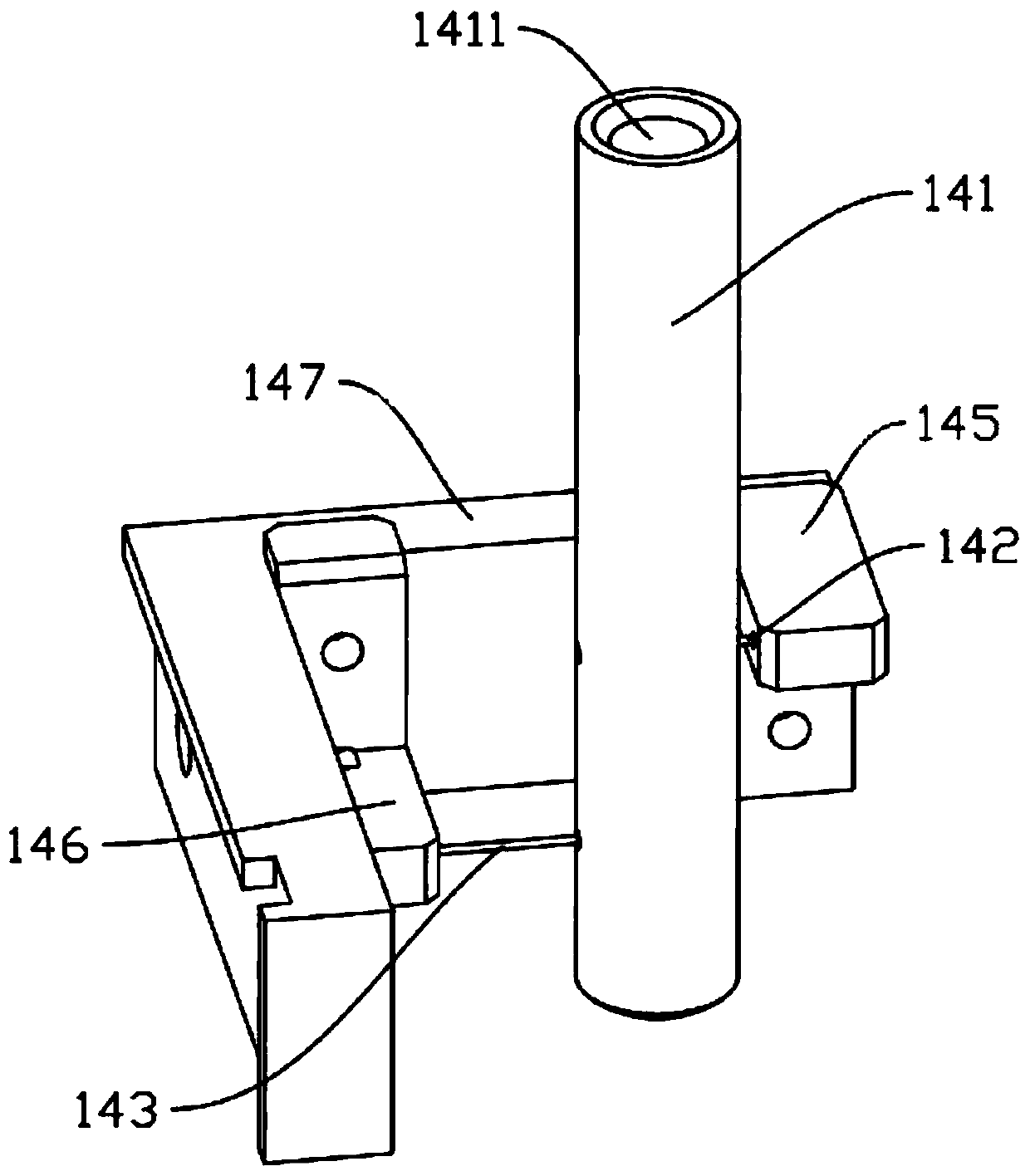

[0031] Examples, see Figure 1 to Figure 5, a spring feeding device 1 for optical fiber connector assembly provided in this embodiment includes a first handling manipulator 11, a spring feeding tube 12, a spring displacement mechanism 13 and an output device arranged on the spring feeding tube 12. The distributing mechanism 14 at the end, the first handling manipulator 11 is arranged on one side of the spring feeding pipe 12, the distributing mechanism 14 includes a distributing cylinder 141 and an upper distributing needle 142 and a lower distributing needle 143 arranged horizontally A material distribution through hole 1411 is provided through the upper and lower end surfaces of the material distribution cylinder 141, and the upper material distribution needle 142 and the lower material distribution needle 143 are inserted into the material distribution cylinder 141 corresponding to the material distribution through hole 1411, A distributing needle driving mechanism for driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com