Multifunctional elevator testing system with self-defined settings

A testing system and multi-functional technology, applied in lifts, transportation and packaging, etc., can solve the problems of single tester, low detection efficiency, high labor cost, etc., and achieve reasonable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

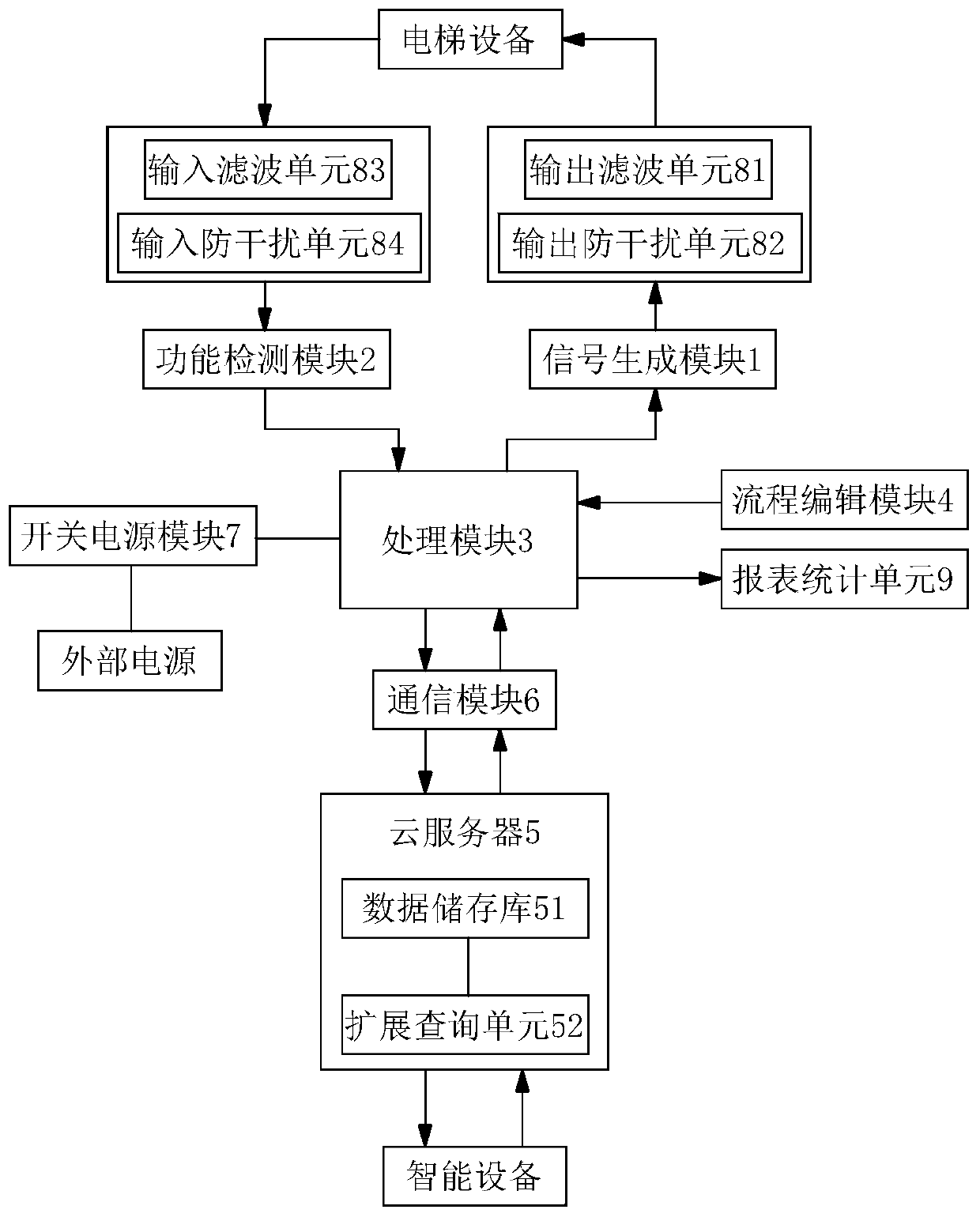

[0024] Such as figure 1 Shown, a kind of elevator testing system comprises:

[0025] Several signal generation modules 1 can respectively output different types of control signals to the elevator control cabinet to trigger the elevator control cabinet to drive the elevator body to run;

[0026] Several function detection modules 2 can respectively detect different operating performance parameters of the elevator body or the elevator control cabinet;

[0027] The processing module 3 is connected with several function detection modules 2 and several signal generation modules 1 respectively, and several function detection modules 2 and / or signal generation modules 1 corresponding to and controlling the function detection module 2 and / or are arranged in the processing module 3 or a functional sub-flow of the operation of the signal generating module 1;

[0028] The flow editing module 4 is connected to the processing module 3, and the function sub-flow can be selected and edited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com