Method for increasing oil reservoir adaptability of self suspending proppant

A technology of reservoir adaptability and proppant, applied in the field of oil reservoir and gas reservoir fracturing, can solve the problems of increasing the specification and quantity of self-suspending proppant products and the cost of production, storage and management, so as to improve reservoir adaptability, technology and so on. Significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for improving the adaptability of a self-suspending proppant reservoir, the method comprising the following steps:

[0020] Step 1. Prepare a self-suspending proppant with the largest amount of thickener adhesion, the proppant is quartz sand, ceramsite or a mixture of the two, and the thickener is partially hydrolyzed polyacrylamide or functional polymer or guar gum (one or more mixtures of carboxymethyl guar gum, hydroxypropyl guar gum, carboxymethyl hydroxypropyl guar gum), the binder is sucrose, polyol resin or resin material;

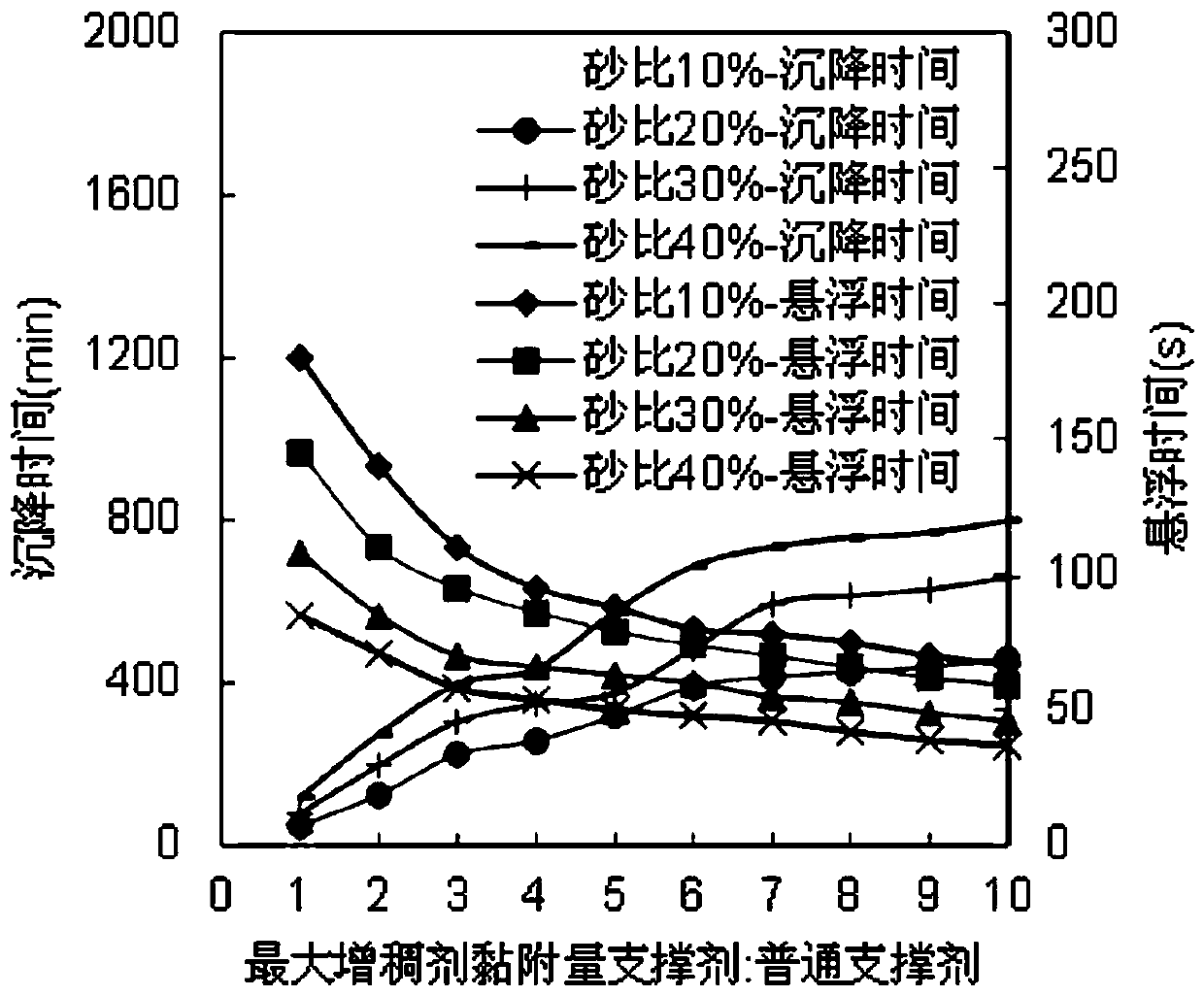

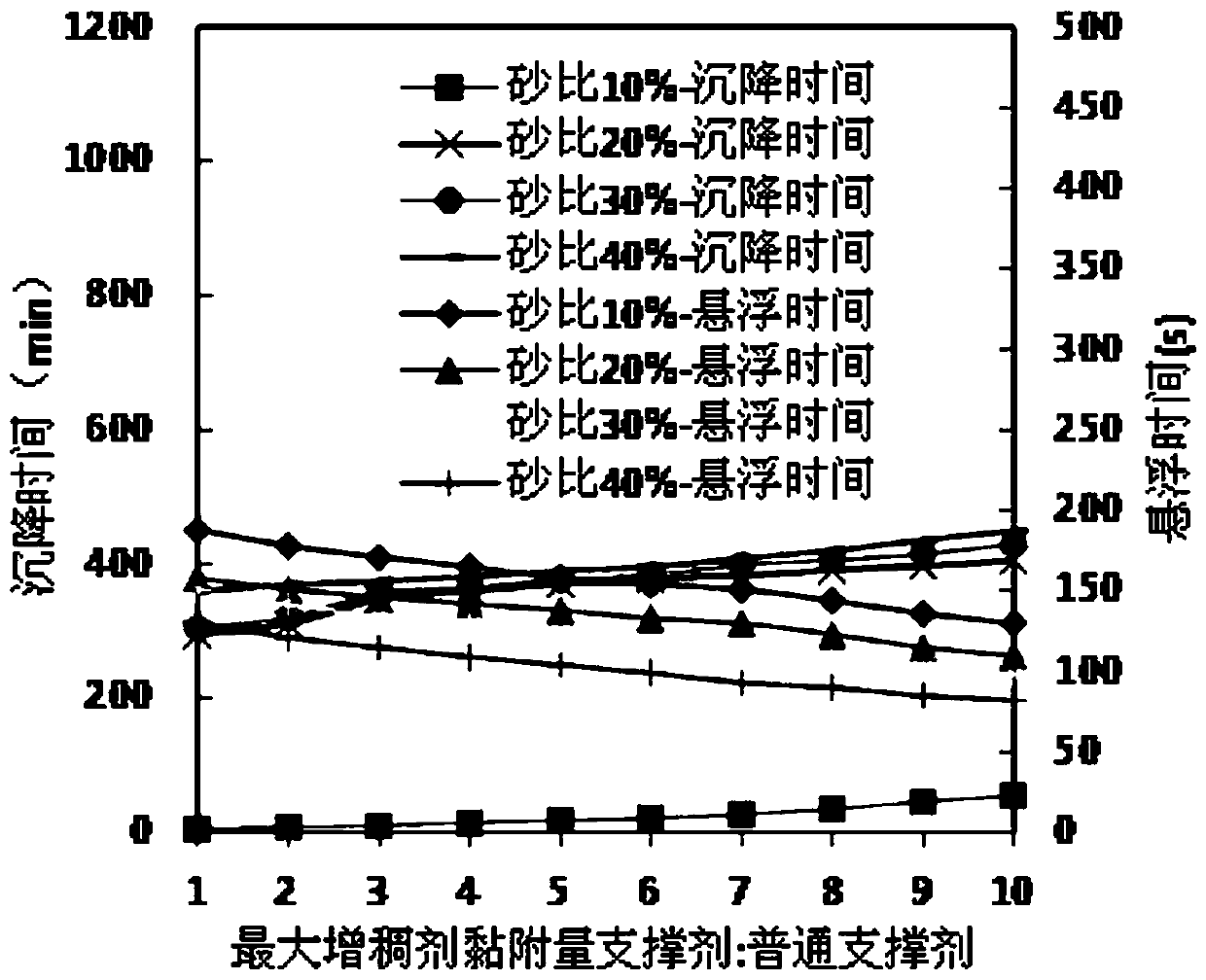

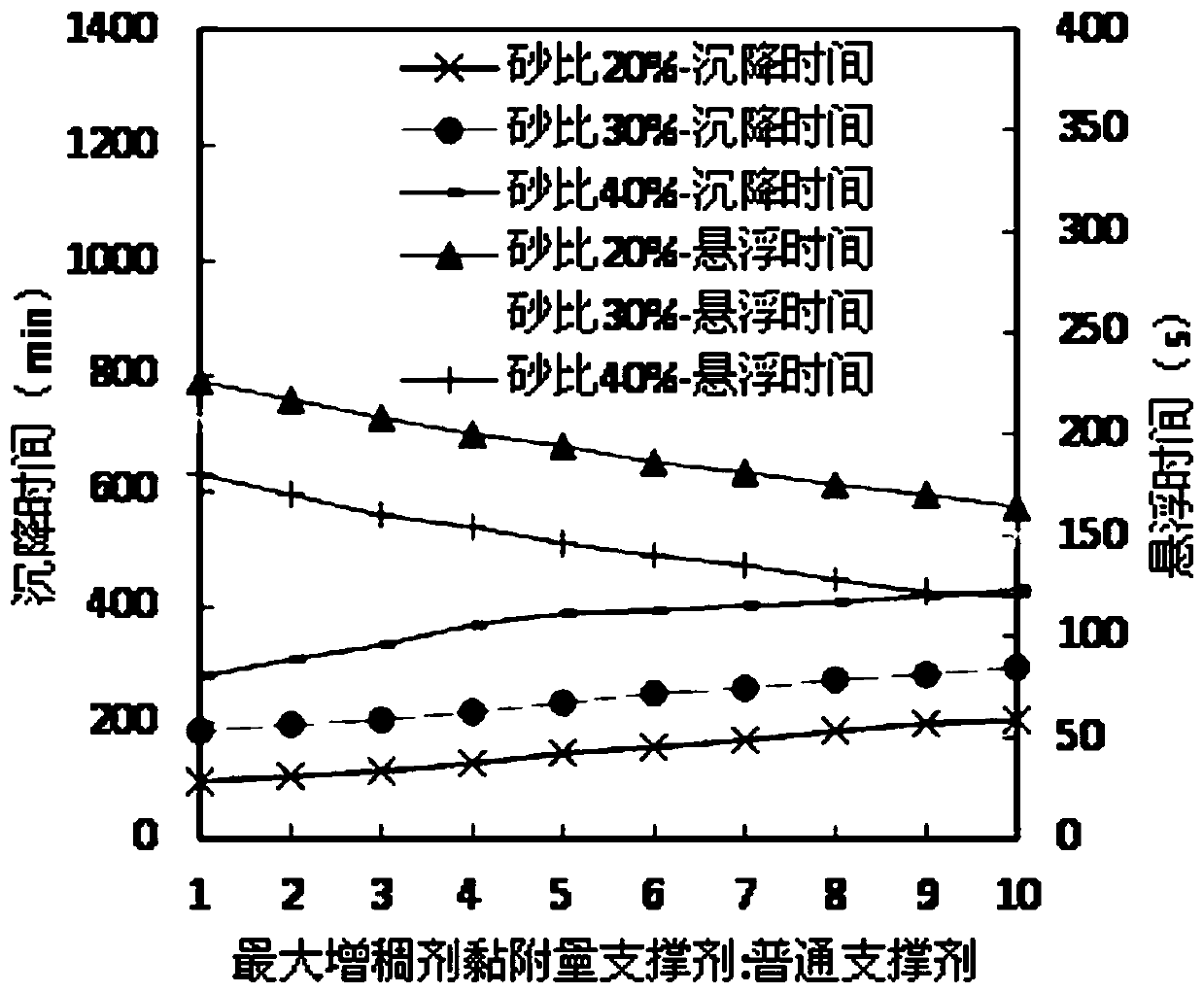

[0021] Step 2. The self-suspending proppant with the largest amount of thickener adhesion and the common proppant (the proppant used to make the self-suspending proppant) are adjusted according to the ratio of 10:1, 9:1, 8:1, 7:1, 6:1, Different mixing ratios of 5:1, 4:1, 3:1, 2:1 and 1:1 are mixed to obtain mixed proppant; under the conditions of target reservoir temperature, solvent water and "liquid:sand" ratio Measure the comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com