Preparation method of euphausia superba active oligopeptide, euphausia superba active oligopeptide prepared by method and application

An Antarctic krill and active technology, applied in the preparation of Antarctic krill active oligopeptides, in the field of Antarctic krill active oligopeptides, can solve the problems of complex operation and high cost, and achieve simplified operation procedures, short time consumption and low sodium content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

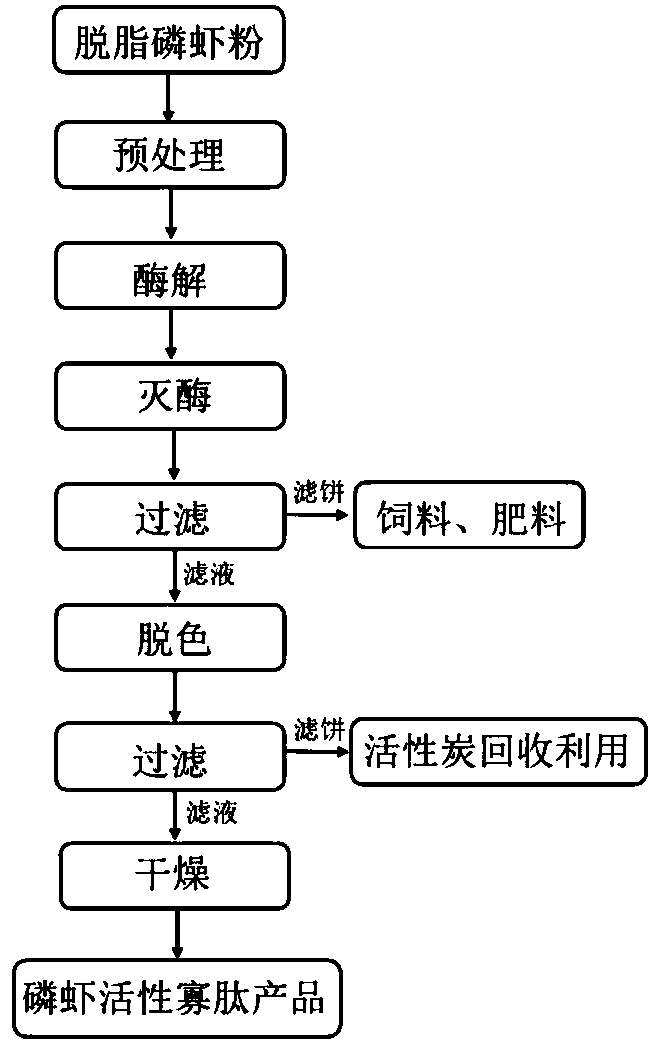

[0038] (1) Raw material pretreatment: Soak and wash defatted krill powder and tap water according to the ratio of 1:15, and wash for 3 times in total. After natural sedimentation, the washing solution is removed by pouring method;

[0039](2) Enzymolysis: mix pretreated defatted krill powder (by dry weight) with distilled water at a ratio of 1:10, and add 2% alkaline protease (enzyme activity 2) from Henan Yangshao Biochemical Engineering Co., Ltd. to the mixed solution. ×10 5 u / g), hydrolysis at 60℃ for 4.5h;

[0040] (3) Enzyme inactivation: after enzymatic hydrolysis for a period of time, the temperature is raised to 90°C to inactivate the enzyme for 15 minutes;

[0041] (4) Filtration: after the enzymolysis solution is cooled, carry out vacuum filtration to obtain solid residue and filtrate. The filtrate is an Antarctic krill protein peptide solution obtained by enzymolysis from defatted krill powder, and the color is dark brown;

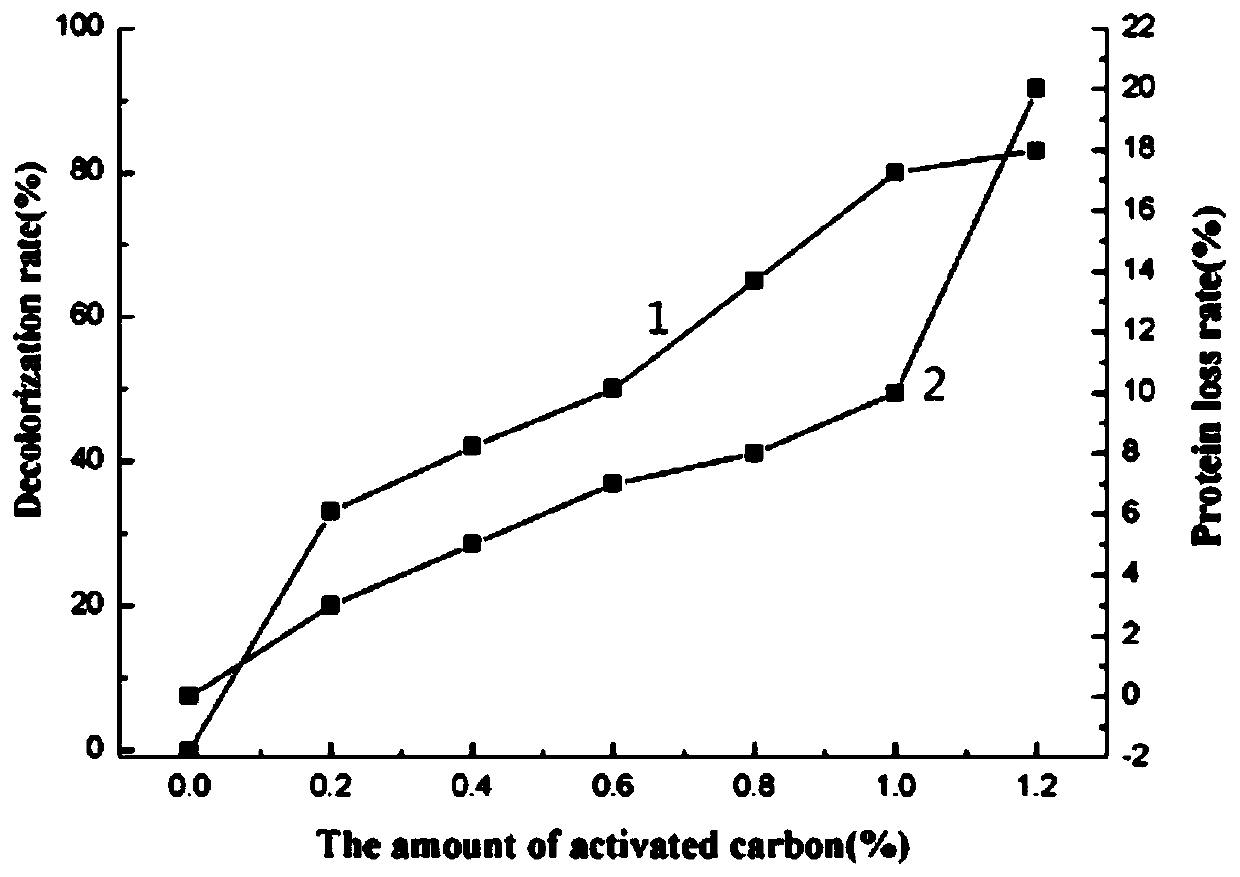

[0042] (5) Decolorization: add 1% activ...

Embodiment 2

[0046] (1) Raw material pretreatment: Soak and wash defatted krill powder and tap water according to the ratio of 1:15, and wash for 3 times in total. After natural sedimentation, the washing solution is removed by pouring method;

[0047] (2) Enzymolysis: pretreated defatted krill powder (by dry weight) is mixed with distilled water at a ratio of 1:10, and 2% alkaline protease (enzyme activity) of Nanning Pangbo Biological Engineering Co., Ltd. is added to the mixed solution. 2×105u / g), hydrolyzed at 60℃ for 4.5h;

[0048] (3) Enzyme inactivation: after enzymatic hydrolysis for a period of time, the temperature is raised to 90°C to inactivate the enzyme for 15 minutes;

[0049] (4) Filtration: Vacuum suction filtration is carried out after cooling the solution after the enzyme is deactivated to obtain a solid residue and a filtrate. The filtrate is an Antarctic krill protein peptide solution obtained by enzymolysis from defatted krill powder, and the color is dark brown ;

...

Embodiment 3

[0054] (1) Raw material pretreatment: Soak and wash defatted krill powder and tap water according to the ratio of 1:15, and wash for 3 times in total. After natural sedimentation, the washing solution is removed by pouring method;

[0055] (2) Enzymolysis: mix pretreated defatted krill powder (by dry weight) with distilled water at a ratio of 1:10, add 2% alkaline protease (enzyme) from Hebei Gebeida Biotechnology Co., Ltd. to the mixed solution Live 2×10 5 u / g), hydrolysis at 60℃ for 4.5h;

[0056] (3) Enzyme inactivation: after enzymatic hydrolysis for a period of time, the temperature is raised to 90°C to inactivate the enzyme for 15 minutes;

[0057] (4) Filtration: Vacuum suction filtration is carried out after cooling the solution after the enzyme is deactivated to obtain a solid residue and a filtrate. The filtrate is an Antarctic krill protein peptide solution obtained by enzymolysis from defatted krill powder, and the color is dark brown ;

[0058] (5) Decolorizati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap