Tool set for changing downhole damaged casing and cementing

A casing and cementing technology, applied in casing, wellbore/well components, drill pipe, etc., can solve the problems of many construction steps, small size, complicated procedures, etc., and achieve the effect of ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

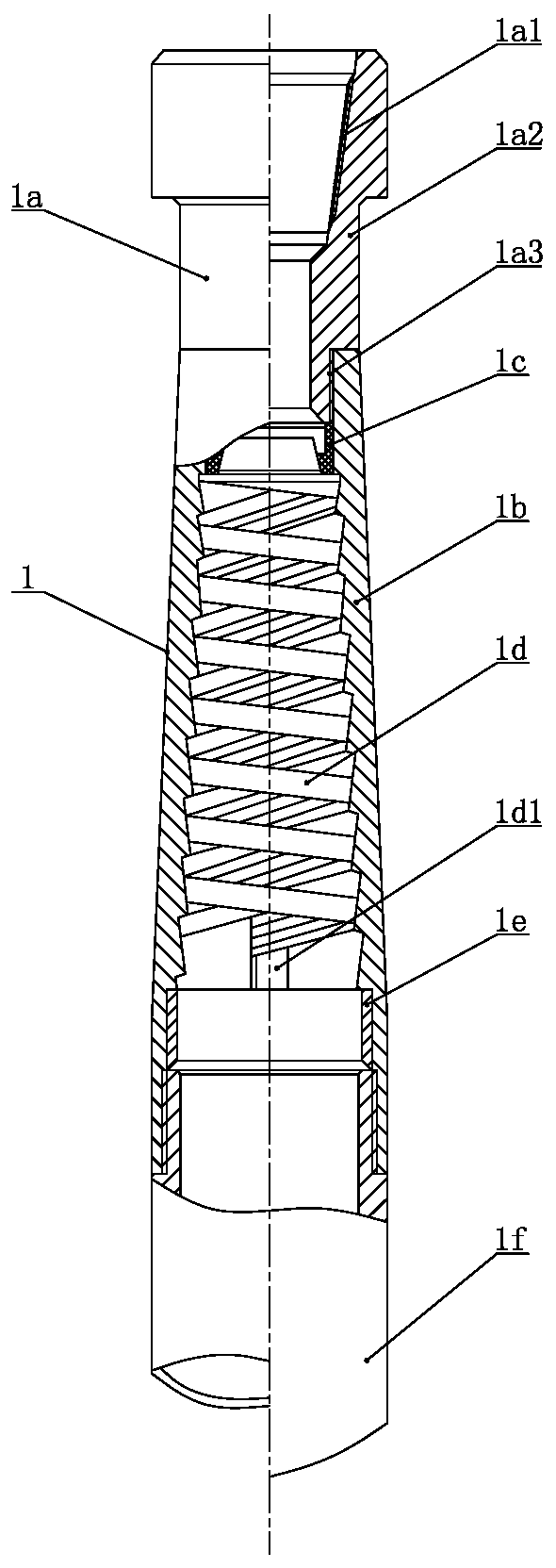

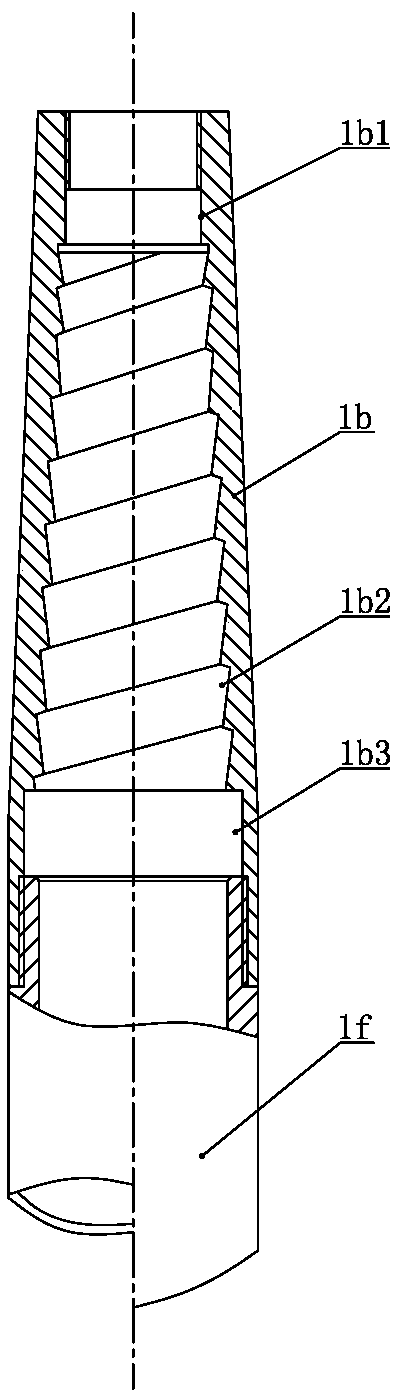

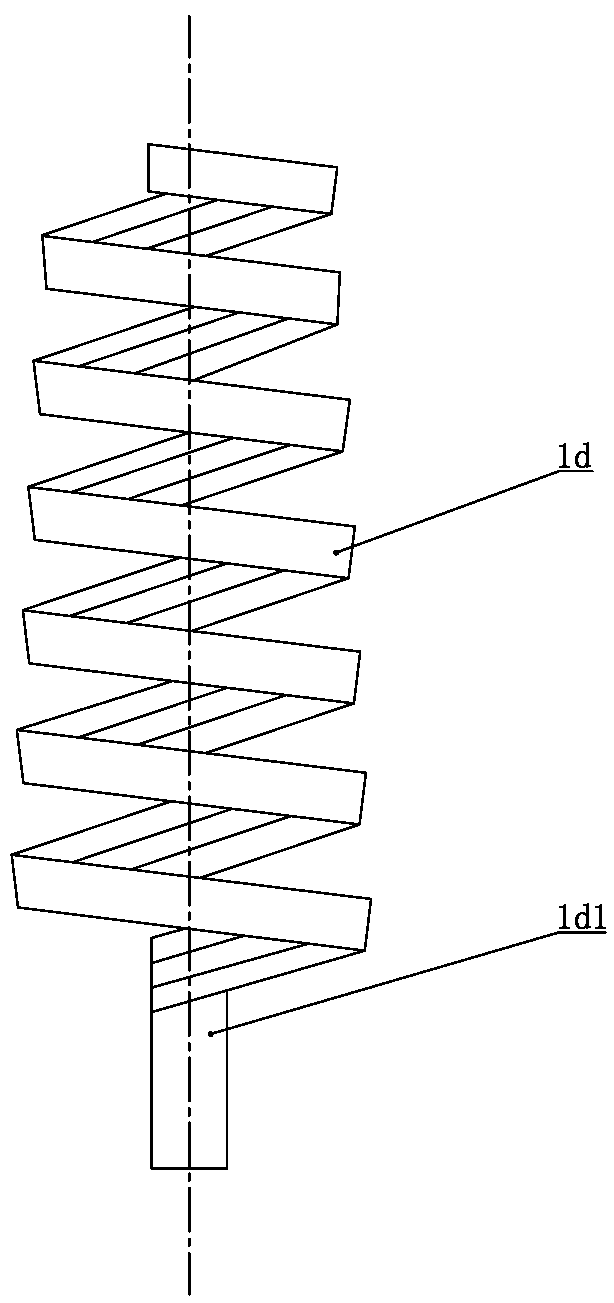

[0028] The downhole damaged casing replacement and cementing tool set of the present invention includes a hydraulic inner cutter, a downhole fishing tool 1 , a remaining casing milling tool 2 and an external butt joint cementing tool 3 . During the casing replacement operation, first use the packer 5 to block the inner cavity of the remaining casing 4 to prevent blowout, and then use the hydraulic internal cutter to cut off the casing that needs to be pulled out. Most casings can be drilled while drilling For the short casing that has been broken and fallen into the well, use the downhole fishing tool 1 to salvage and take it out; then use the remaining casing milling tool 2 to grind and mill the fish top chamfer on the remaining casing 4, The floating hoop 6 is connected to the upper end of the external butt joint cementing tool 3, and the new casing 7 is connected above the floating hoop 6, and then the new casing 7 is lowered with the drilling tool. The top of the fish is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com