A Design Method of Axial Flow Pump Impeller Based on Wheelbase

A design method, technology for axial flow pumps, applied in the direction of axial flow pumps, components of pumping devices for elastic fluids, design optimization/simulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

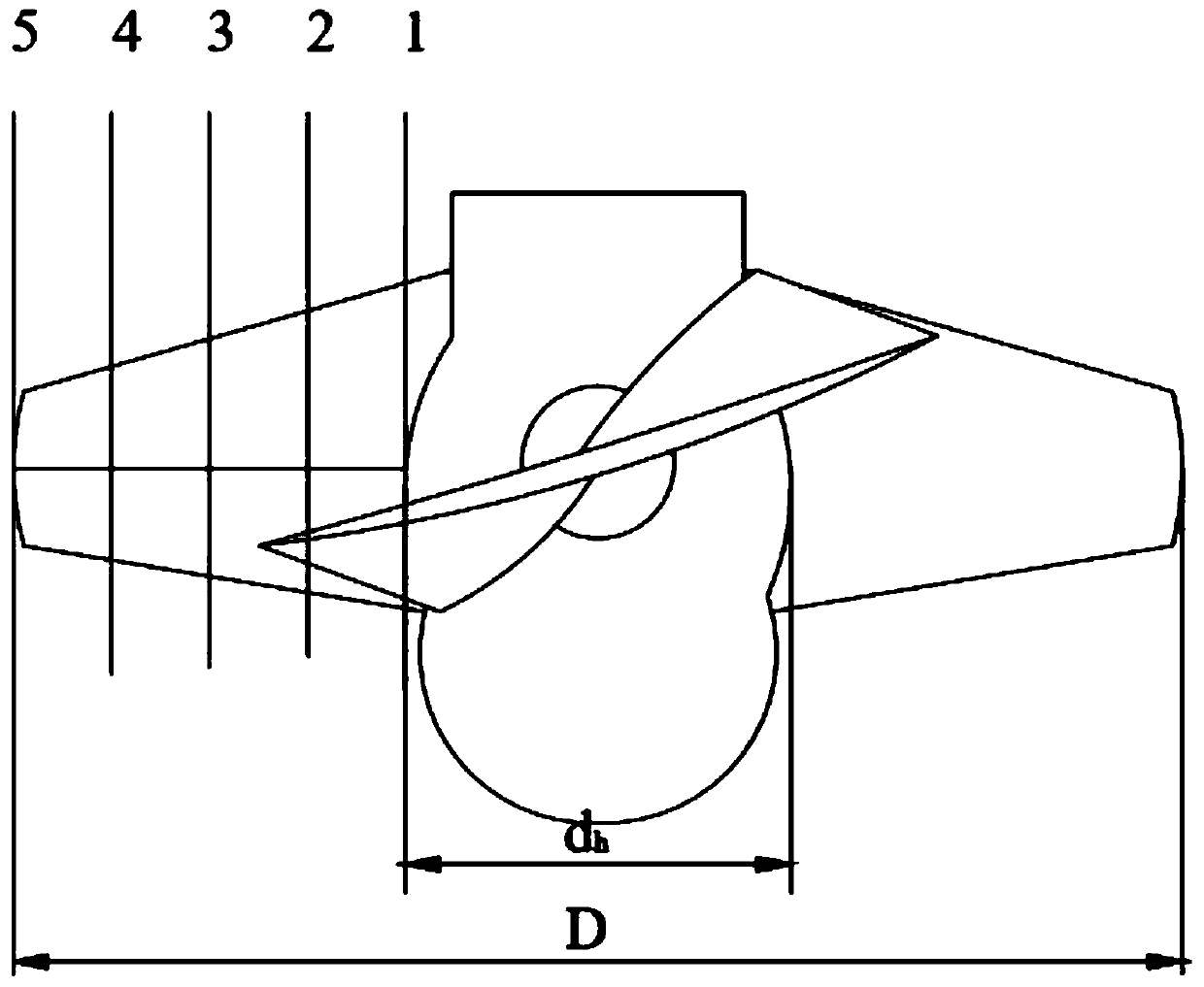

[0085] Axial flow pump design flow rate Q=0.35m 3 / s, head H=6.72m, speed n=1450r / min, design axial length L 1 = 26mm. The present invention is further described below:

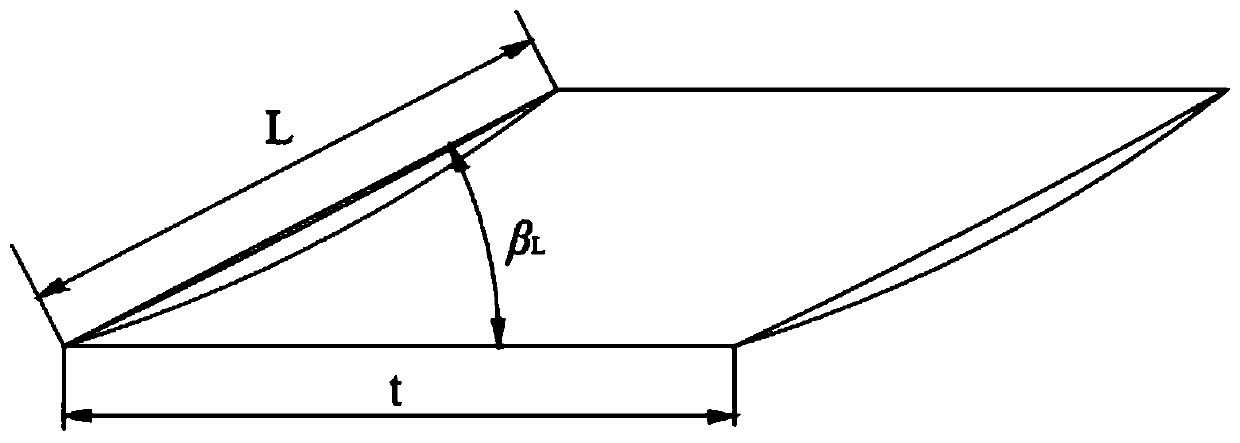

[0086] 1. Determine the airfoil chord length l and blade placement angle β by flow Q, head H, and speed n L , calculated as follows:

[0087] (1) Determine the number of impeller design sections and the number of blades

[0088]

[0089] According to the table below, take the number of impeller sections as 5

[0090] Specific speed n s

n s ≤450

450≤n s ≤800

800≤n s

Number of impeller sections 4 5 6

[0091] According to the following table, take z=4;

[0092] Specific speed n s

0~600 600~850 850~1500 blade number z 3 4 5

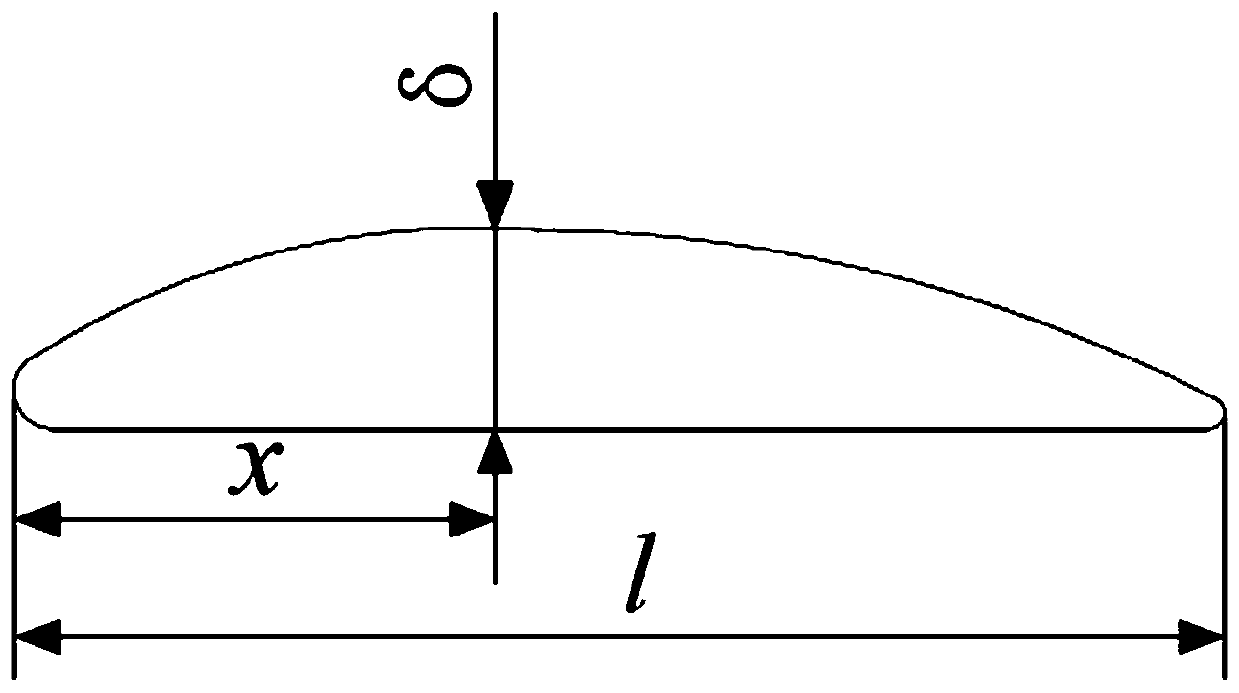

[0093] (2) Airfoil chord length l

[0094] The airfoil chord length l of section 5 5

[0095] According to the table below, take a=6;

[0096] blade number z 3 4 5 Correction factor a 3.4~5.8 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com