3D glass grinding machine

A grinding machine and glass technology, which is applied in the direction of grinding machine tool parts, grinding workpiece supports, surface polishing machine tools, etc., can solve the problems of increasing the processing cost investment of enterprises, low equipment processing efficiency, and poor applicability of equipment processing. Improve processing applicability and practicability, flexible polishing and grinding operations, and ensure stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

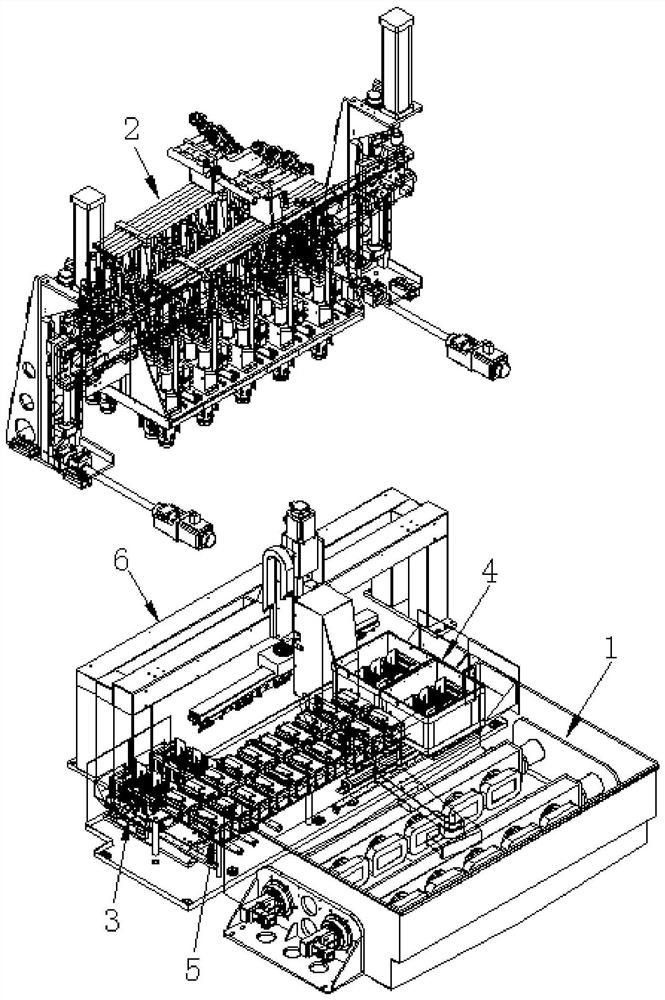

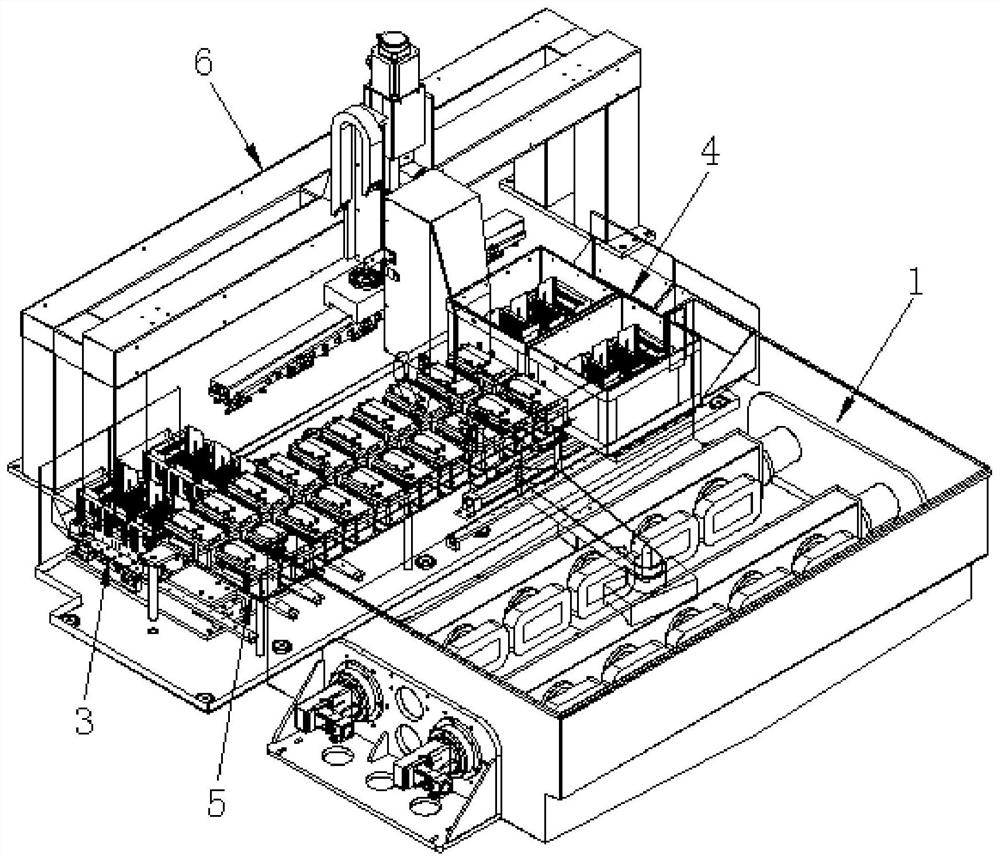

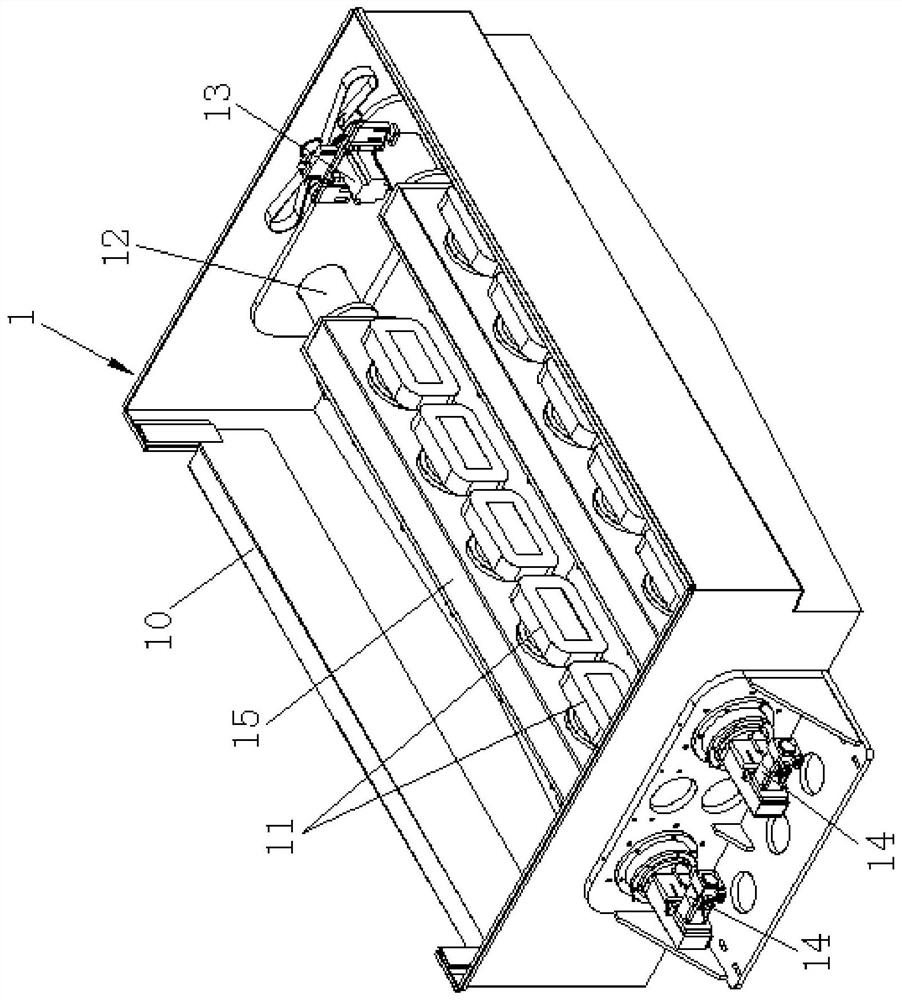

[0045] Please refer to the attached Figure 1~5 As shown, the 3D glass grinding machine of the present invention includes a polishing device and a pick-and-place device, the polishing device includes a processing tank 1 and a polishing system 2, and the tank body 10 of the processing tank 1 is provided with Several carriers 11 for receiving products to be polished (3D glass), and several carriers 11 can rotate relative to the tank body 10, the polishing system 2 has several polishing heads 20, and several polishing heads 20 can be adjusted and rotated relative to the tank body 10, so that several of the polishing heads 20 can cooperate with several of the carriers 11, and cooperate to polish the products to be polished placed on the several of the carriers 11 Grinding; the pick-and-place device has a receiving box A3 for placing the product to be polished, a receiving box B4 for placing the polished product, a calibration device 5 for correcting and positioning the product, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com