Multi-pore diameter rolling cage screen and method of preparing particle-containing ceramic product by using the same

A technology of ceramic products and rolling cage screen, which is applied in the field of building ceramic tiles, can solve the problems of many failures, many managements, and the operability needs to be further improved, and achieves the effect of reducing equipment investment and reducing floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

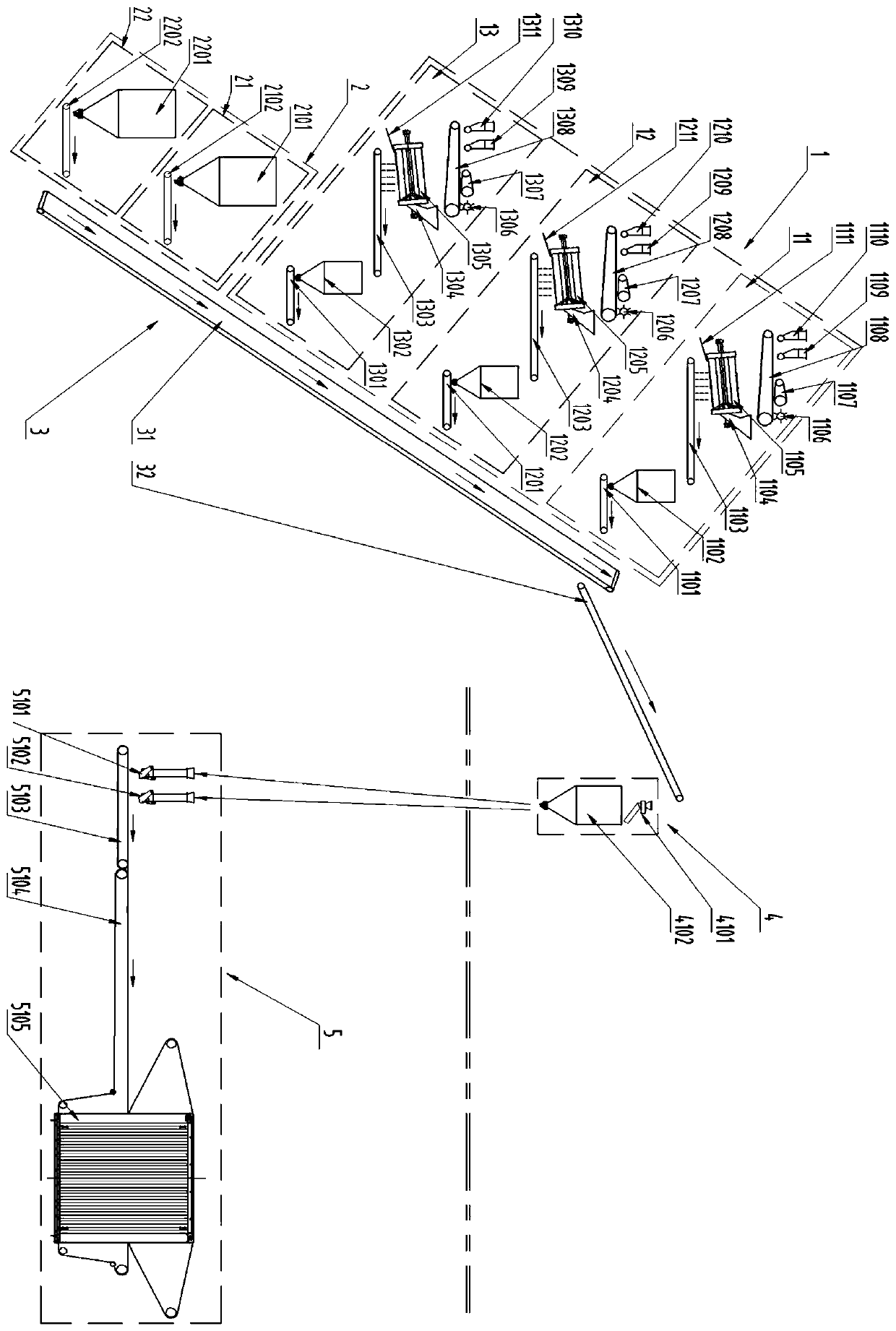

[0048] Such as figure 1 As shown, the present invention discloses a production equipment for preparing ceramic products containing granular elements through a multi-diameter rolling cage sieve. The equipment includes a granulation, storage, and delivery module 1, a green body powder storage and delivery module 2, a delivery carrier module 3, Mixed material storage, conveying module 4 and distribution and pressing equipment module 5;

[0049] Among them, the granulation, storage, and delivery module 1 includes the granulation device, the transfer bin and the parts of the metering belt scale (11, 12, 13 in the figure); the green body powder storage and delivery module 2 includes the green body powder transfer bin and The metering belt scale (21, 22 in the figure) below it; the transfer carrier module 3 includes a first transfer carrier 31 for receiving and loading a variety of particle mixtures and a second transfer carrier for transferring the mixture to the top platform of the...

Embodiment 2

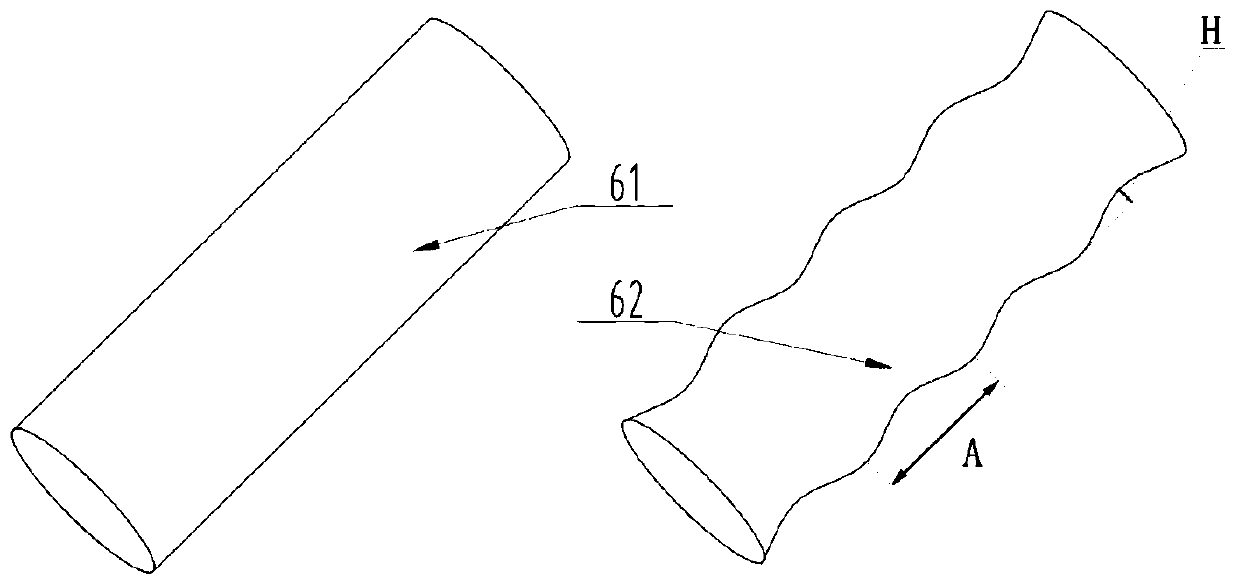

[0067] In the above-mentioned embodiment, the cylindrical cage-shaped rolling cage sieve 61 is replaced with a corrugated column cage-shaped rolling cage sieve 62. The corrugated column cage-shaped main body includes a corrugated cage wall, and the longitudinal section of the corrugated cage wall is regular or irregular corrugations. The height difference H between the crest and the trough is 10cm to 50cm, and the axial spacing A between adjacent crests is greater than 20cm. The multi-aperture rolling cage sieve of the present invention and ceramic products containing granular elements can also be produced.

Embodiment 3

[0069] After step six and before step seven in the above embodiment, enter the glaze line, spray digital color patterns of ceramic ink and protective glaze on the surface of the green body, or directly spray protective glaze / or various ceramics without printing color digital patterns The dry granular material is used to prepare the multi-diameter rolling cage sieve of the present invention and ceramic products containing granular elements prepared therefrom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap