Sheet workpiece punching technology

A workpiece and sheet technology, applied in the field of sheet workpiece blanking process, can solve the problems of large drop height and workpiece deformation, and achieve the effect of small drop height, preventing workpiece edge deformation and reducing drop height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

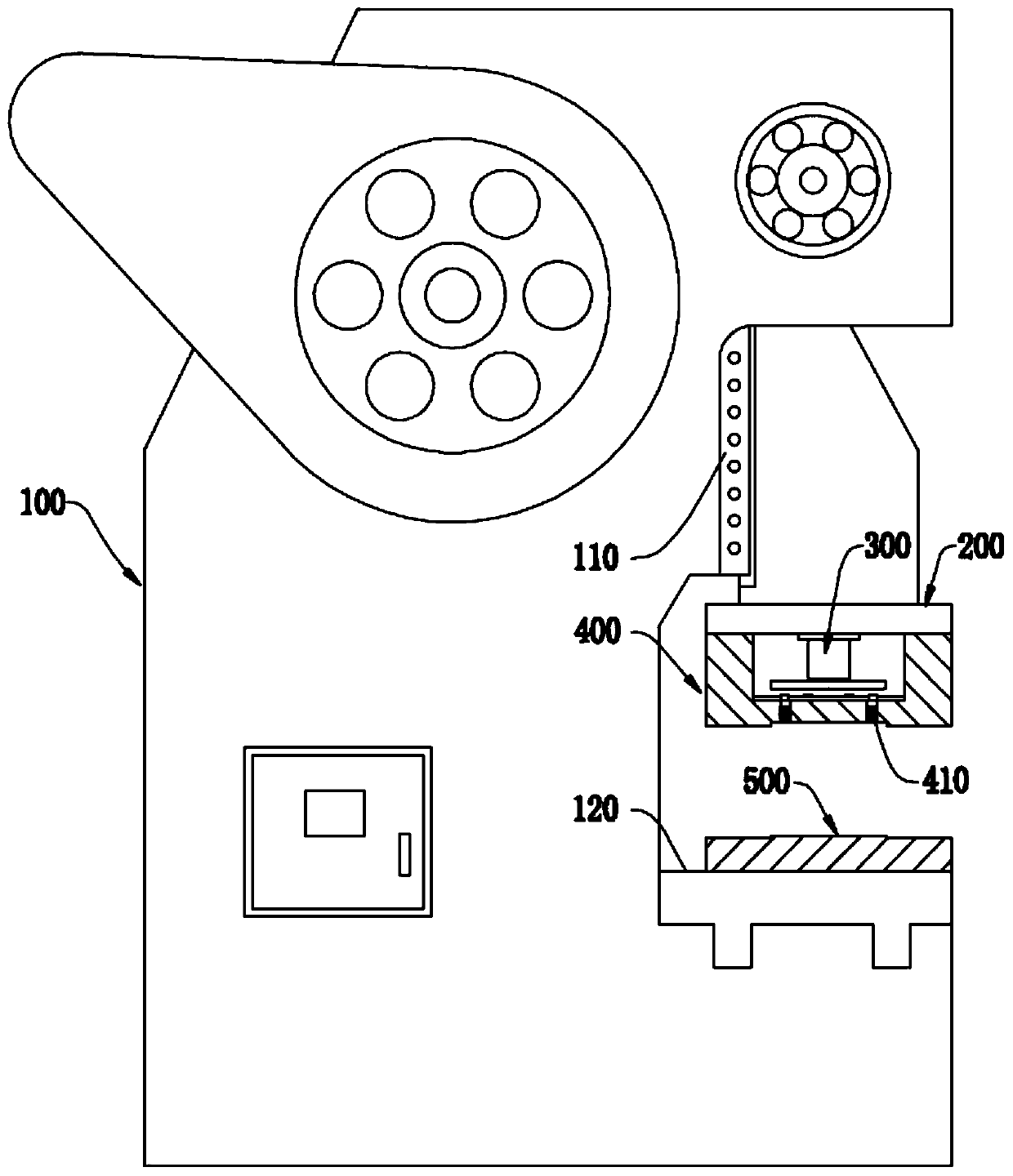

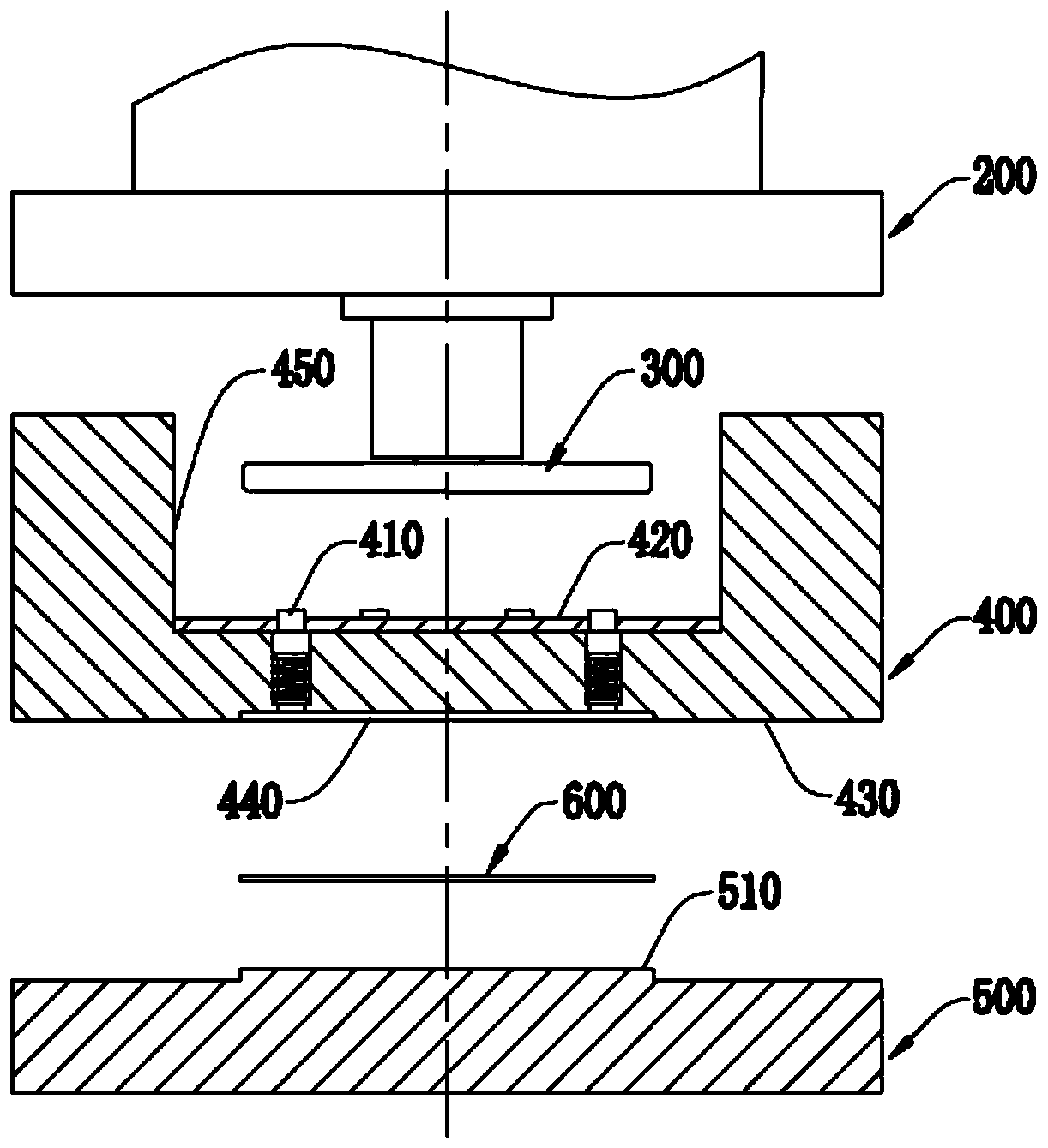

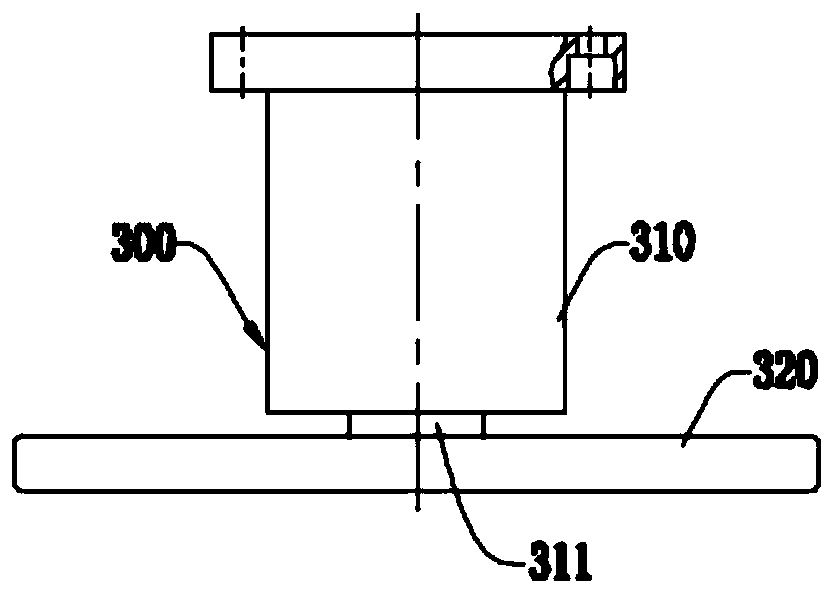

[0050] A blanking process for thin plate workpieces, using a punching machine to blank materials into workpieces 600, such as figure 1 , 2 As shown, the punch press includes a punch body 100, a die base 200, an upper die assembly 400 and a lower die 500, the front side of the punch body 100 is provided with a slide rail 110, and the die base 200 is slidably connected to the slide rail 110, and is connected with the power unit arranged in the punch body 100, and is driven by the punch body 100 to move up and down along the slide rail 110; the upper die assembly 400 is fixed on the bottom of the die base 200, and It is detachably connected with the mold base 200 by bolts; the lower mold 500 is fixed on the mounting platform 120 on the front side of the punch body 100, and cooperates with the upper mold assembly 400 up and down; the bottom of the mold base 200 is provided with The oil cylinder feeding device 300, the middle part of the upper mold assembly 400 is provided with a ...

Embodiment 2

[0065] A sheet blanking process of this embodiment is basically the same as that of Embodiment 1, the difference and improvement is that the oil cylinder feeding device 300 starts within 0.5 seconds after the upper die assembly 400 starts to return, and the oil cylinder After the feeding device 300 is started, the workpiece 600 is ejected out of the upper mold assembly 400. At this time, the upper mold assembly 400 rises within 6 cm, and the workpiece 600 falls at a lower height, which can prevent the workpiece from falling behind due to the excessive rise of the upper mold assembly. Impact deformation.

Embodiment 3

[0067] A blanking process for thin plate workpieces in this embodiment is basically the same as in Embodiment 1 or 2, the difference and improvement is that the length of the floating ejector rod assembly 410 moving down and extending into the mold core groove 440 is at least Workpiece 600 thickness.

[0068] When the depth of the core groove 440 is greater than the thickness of the workpiece 600, the floating ejector rod assembly 410 needs to extend from the bottom of the core groove 440 to the notch of the core groove 440 to eject the workpiece 600 from the core groove 440. When the floating ejector rod assembly 410 moves down, the length extending into the mold core groove 440 is greater than the thickness of the workpiece 600 .

[0069] When the depth of the core groove 440 is just equal to the thickness of the workpiece 600, the floating ejector rod assembly 410 is pushed down by the cylinder beating device 300, and the length extending into the core groove 440 is the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com