Flat tube pushing and limiting device for threading machine

A limit device and belt threading machine technology, which is applied in the field of belt threading machines, can solve the problems of poor shape of the intercooler tube nozzle, high scrap rate, and many waste products of the intercooler tube assembly, so as to improve the success rate of belt threading , improve the qualified rate, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

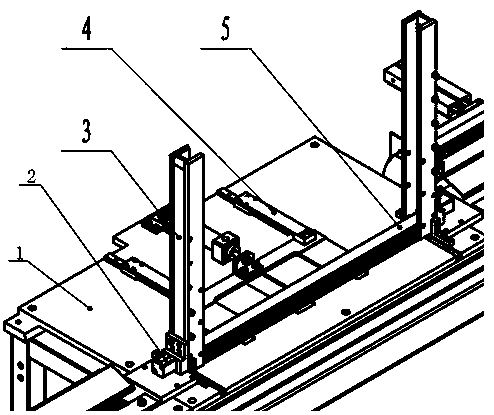

[0029] As shown in the figure, the present invention is a flat tube pushing and limiting device for a belt threading machine. The length of the flat tube is 686mm, and the length of the fins (that is, the spoiler belt) is 342mm, including

[0030] A frame, on which a workbench 1 is arranged;

[0031] The flat tube storage unit is vertically fixed on the workbench 1 for storing the flat tube 5;

[0032] The flat tube pushing unit is installed on one side of the flat tube storage unit, and is used to horizontally push out the flat tube that has been inserted at the bottom of the flat tube storage unit;

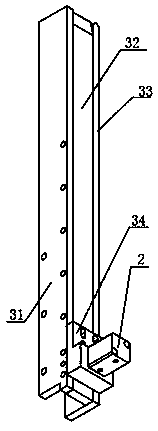

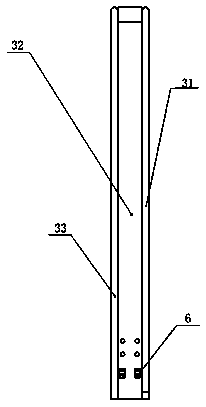

[0033] The flat tube storage unit includes two parallel and vertical lower slides 3. The lower slide is a flat-shaped structure with one side opening surrounded by three panels. The two flat-shaped openings face each other. , Install the cylinder 2 through the cylinder bracket on the back of the shape, and the protruding end of the cylinder 2 passes through the cylinder bracket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com