Myoelectrical complex driving mechanism for foot robot joints

A technology of robot joints and driving mechanisms, applied in motor vehicles, manipulators, program-controlled manipulators, etc., can solve problems such as poor practicability, achieve good practicability, solve uncontrollable compensation torque, and improve control compliance and environmental adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

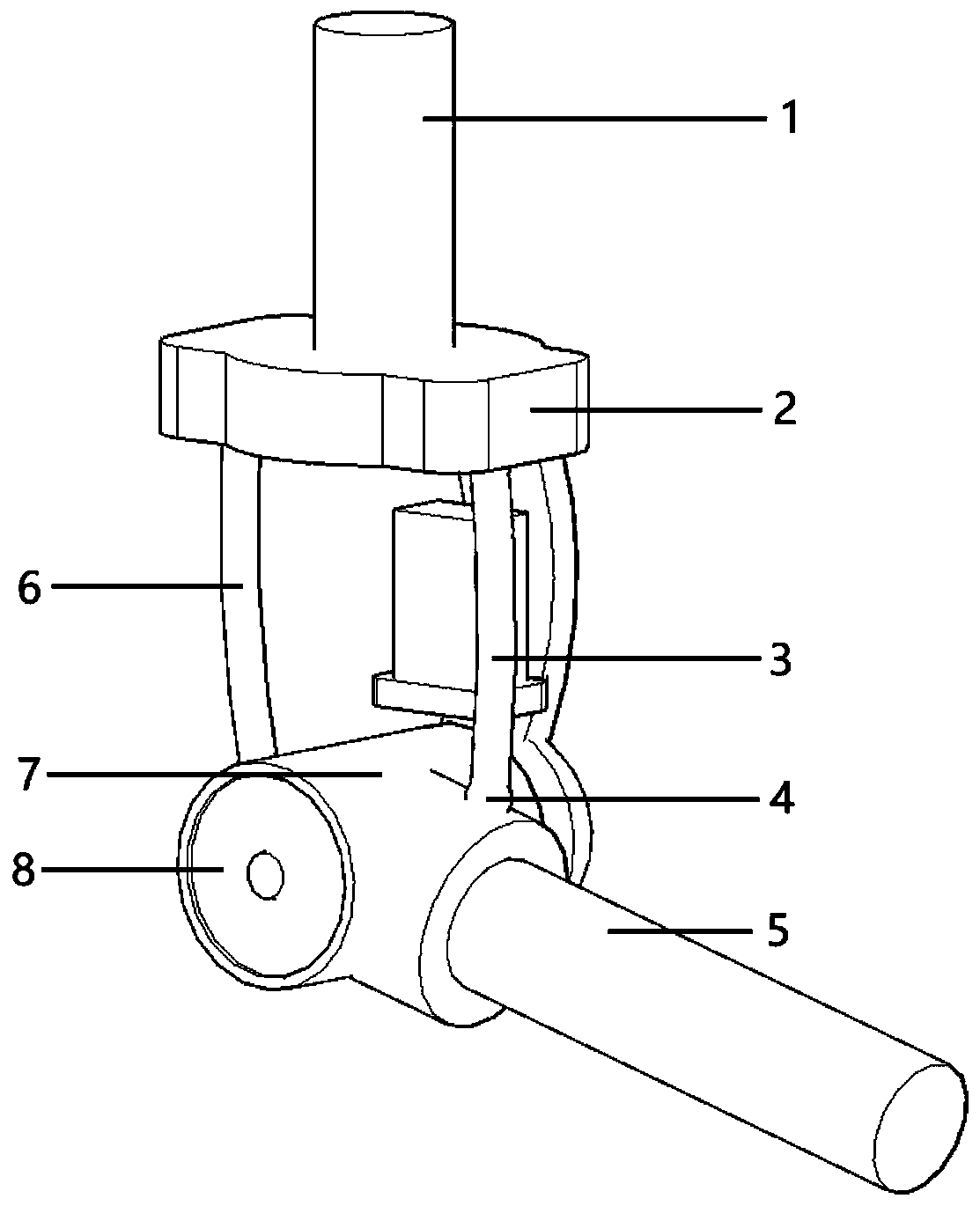

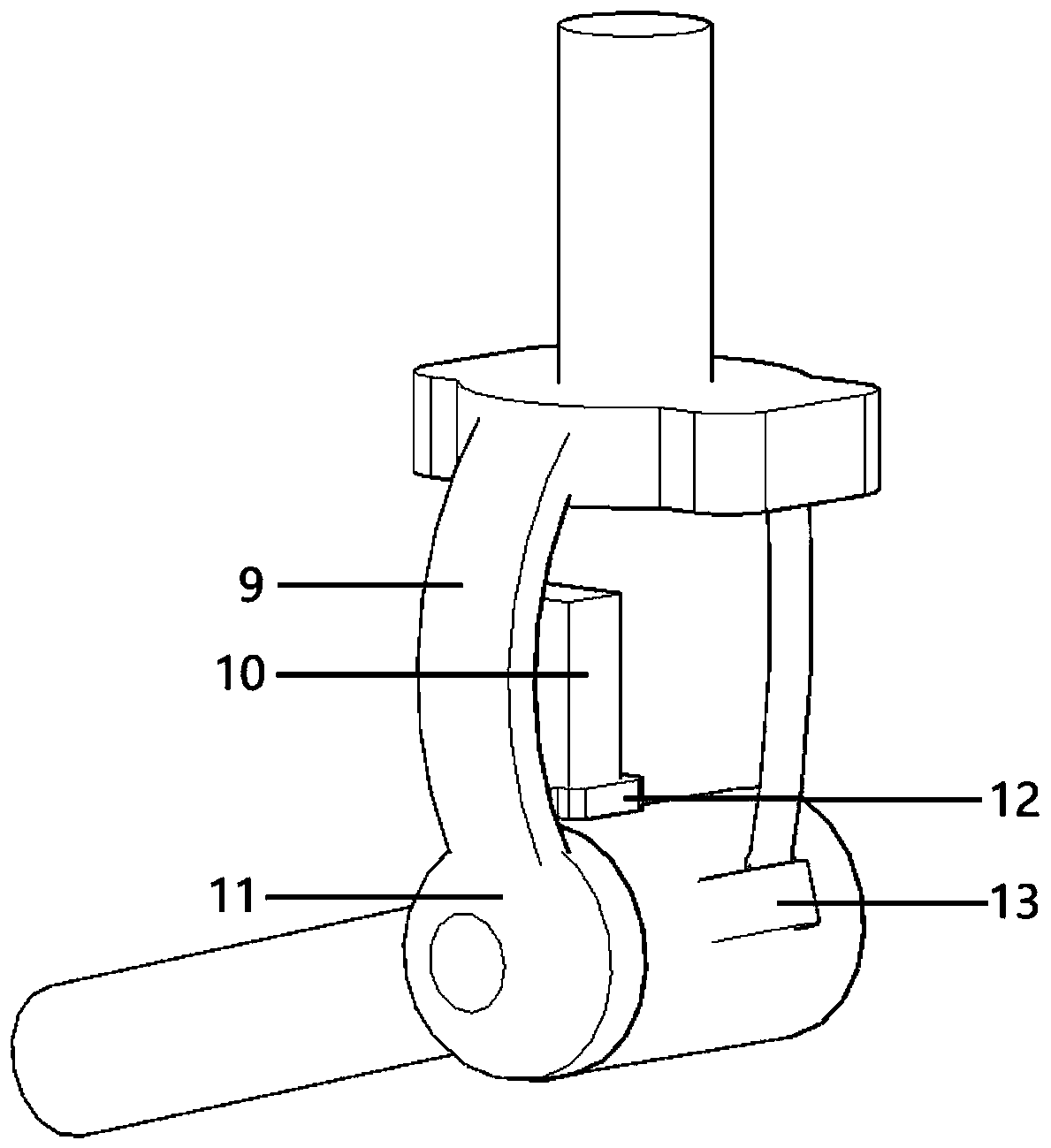

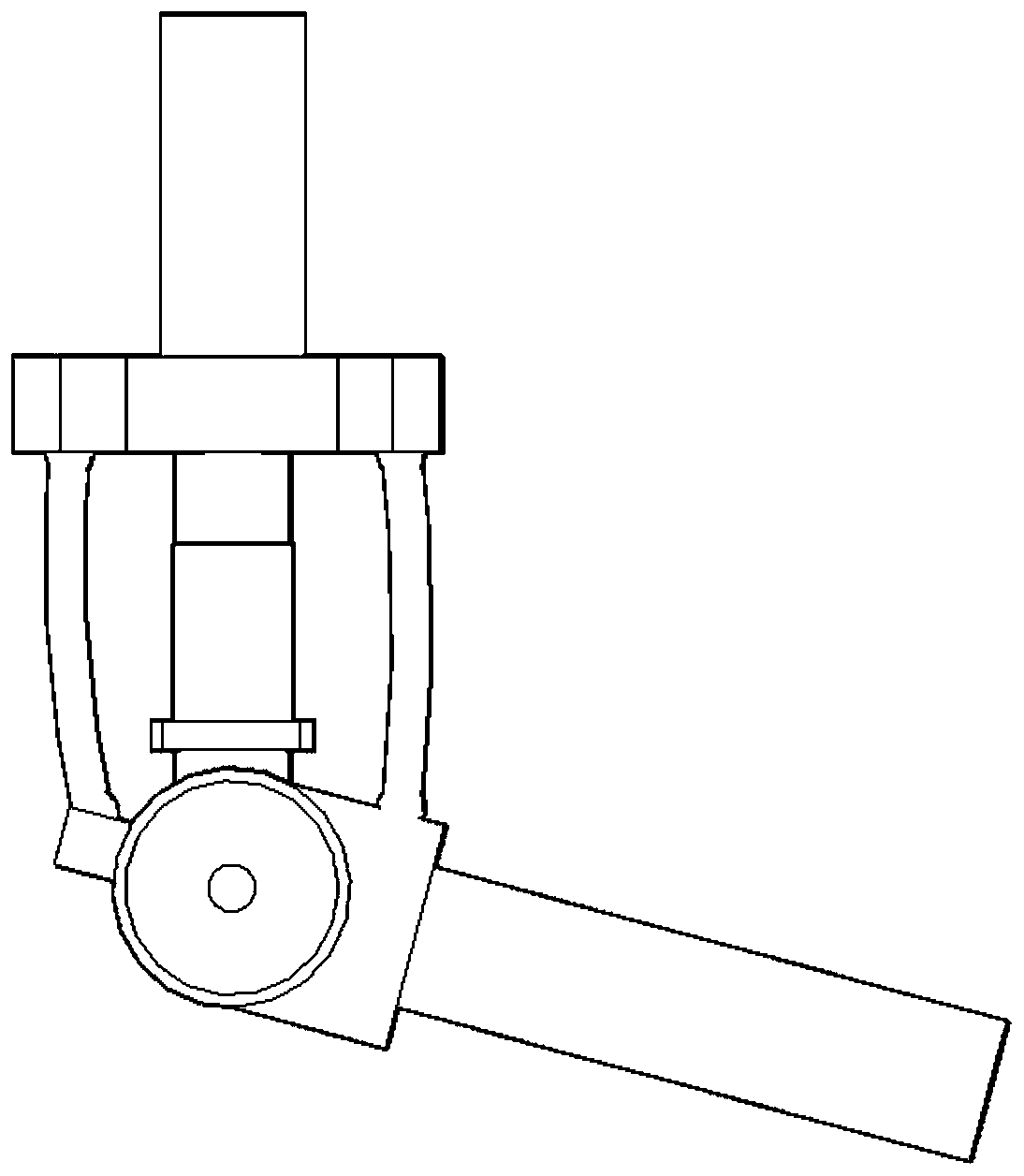

[0024] The following examples refer to Figure 1~6 .

[0025] The electric muscle compound driving mechanism for the joint of the legged robot of the present invention includes an upper bracket 1, a tendon support frame 2, a right tendon 3, a flexible electrode and a fixer 4, a lower bracket 5, a left tendon 6, a connecting shell 7, a motor assembly 8, a connecting Frame 9, controller 10, connecting platform 11 and controller bracket 12.

[0026] The upper part of the upper bracket 1 is a free end connected to other joints, and the lower part of the upper bracket 1 is fixedly connected with the tendon support frame 2 . The tendon support frame 2 plays the role of providing support for the contraction and force application of the tendon. The connecting frame 9 has an arc-shaped structure, providing space for the internal controller 10, and at the same time, the appearance is more similar to the appearance of human muscles. The upper part of the connecting frame 9 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com