Nano-aluminum composite board easy to clean

A technology of nano-aluminum and composite boards, which is applied in the direction of layered products, chemical instruments and methods, and metal layered products, etc., which can solve the problems of composite board installation, ventilation, safety strength, poor thermal insulation effect, and reduced user experience. Easy to adhere to oil stains and other problems, to achieve the effect of convenient assembly, protection of national forest resources, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

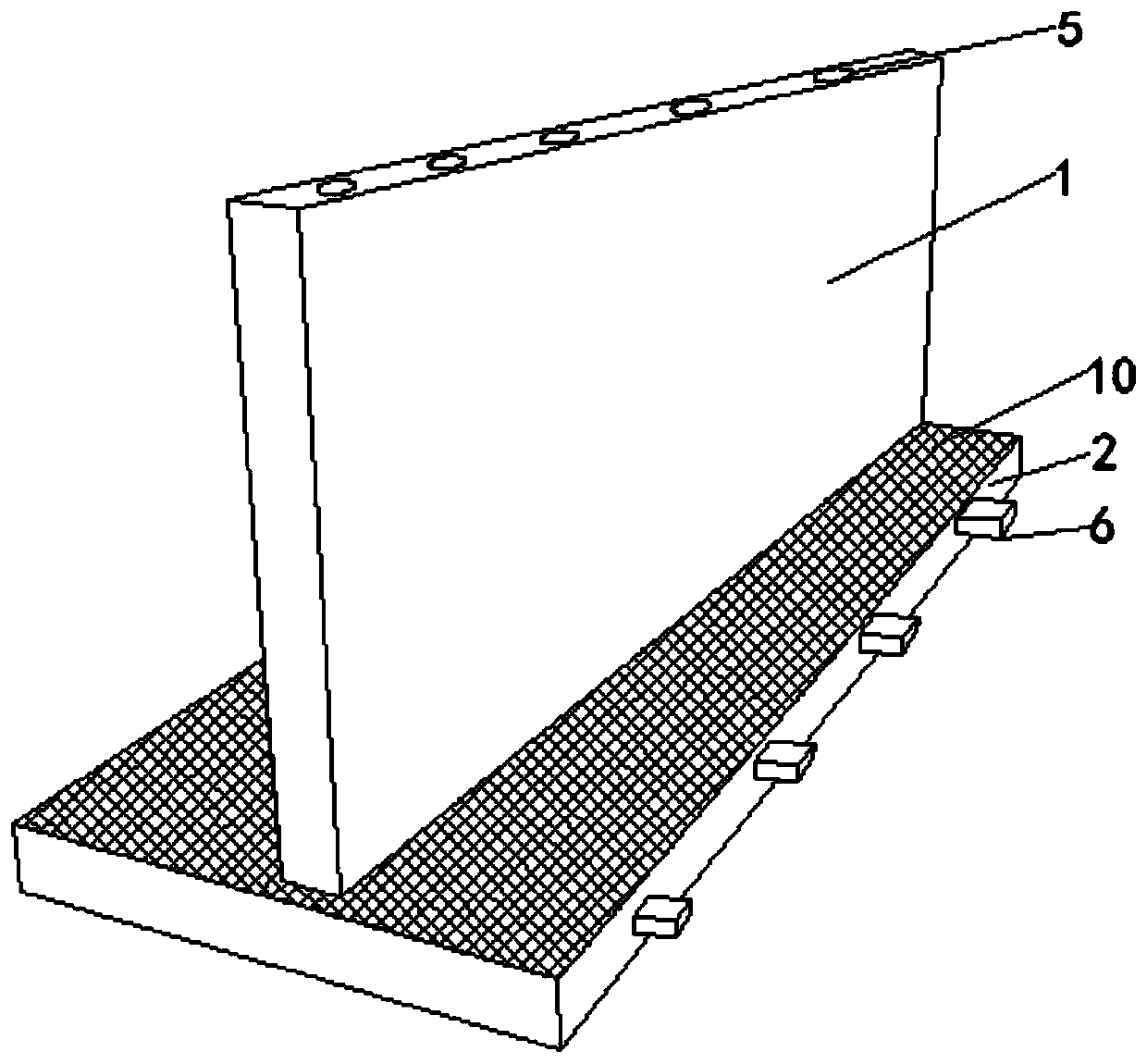

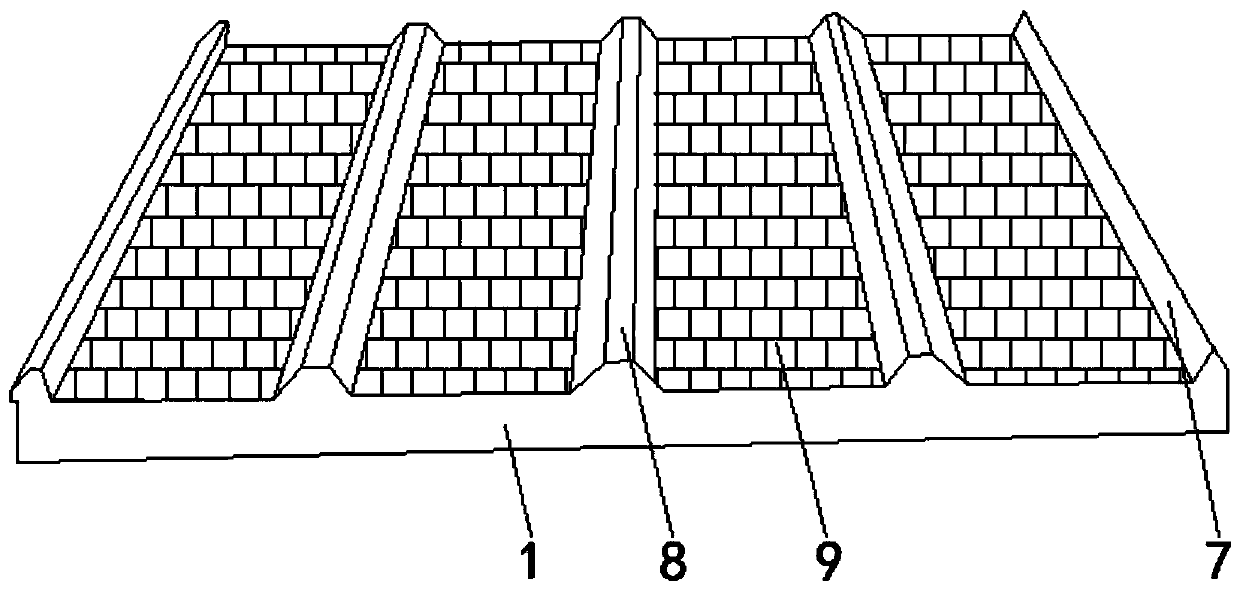

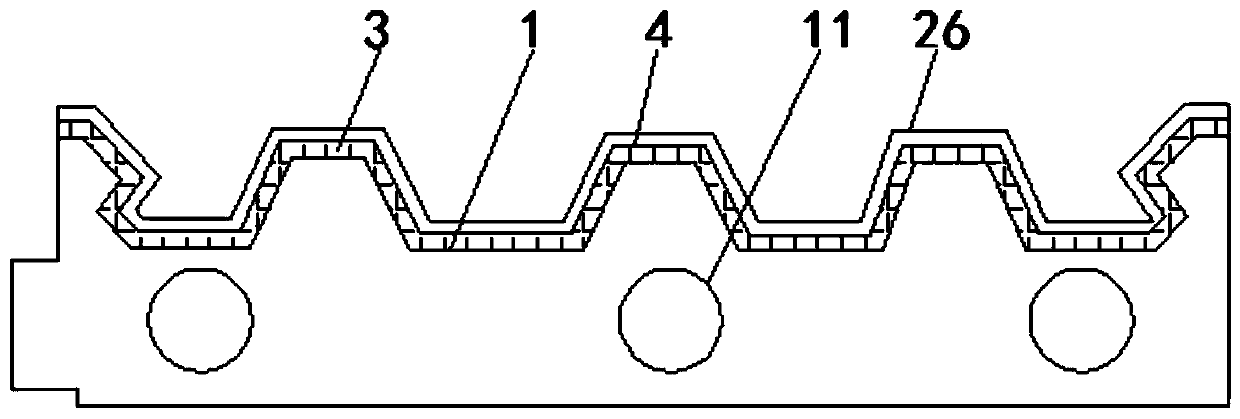

[0021] Refer to attached Figure 1-5 , an easy-to-clean nano-aluminum composite board, comprising a first splint 1, a second splint 2, a splicing plate 3, an adhesive film 4, a through hole 5 and a plug-in rod 6, the first splint 1 and the second splint The two splints 2 are fixedly connected by the splicing plate 3, the adhesive film 4 is fixedly installed on the outer wall of the splicing plate 3, and the first splint 1 is provided with the through holes 5 equidistantly arranged on one side. One end of the through hole 5 runs through the first splint 1 and extends to the inside of the first splint 1, and the through hole 5 is mated with the insertion rod 6 on the outer wall of the second splint 2, so Both sides of the top of the first splint 1 are connected with protruding blocks 7, and a sponge layer 8 between the first splint 1 and the second splint 2 is arranged between the protruding blocks 7, and the sponge The top of the layer 8 is fixedly connected with a wear-resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com