Preparation method of photo-curable resin porous material

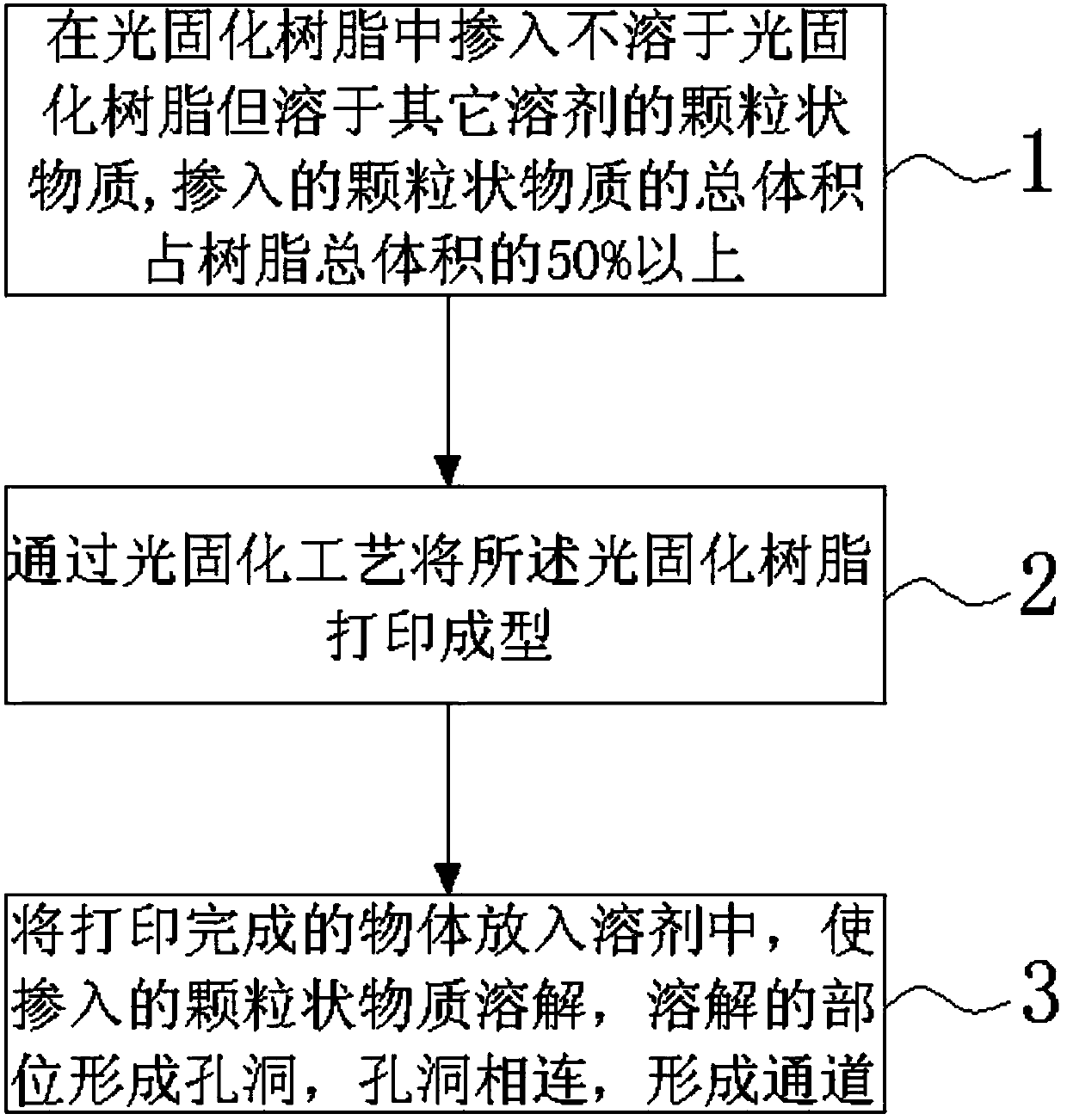

A technology of light-curing resin and porous material, which is applied in the field of preparing porous materials by using light-curing resin through 3D printing technology, can solve the problems of many technological processes, long production time and high rejection rate, and achieve advanced technology, less production process and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Use salt powder as the granular material and water as the solvent.

[0027] 1) According to the design needs, batch production of salt powder with a particle size of about 0.03mm as a "punched" granular substance;

[0028] 2) Add salt powder into the photocurable resin, and the volume ratio of the salt powder mixed with the photocurable resin is 70%;

[0029] 3) The light-curing resin mixed with salt powder is printed and formed by a light-curing 3D printer;

[0030] 4) Put the printed object into the water, so that the mixed salt powder is dissolved in the water;

[0031] 5) After dissolving, a hole is formed in the original part of the salt powder, and the holes are connected to form a channel.

[0032] According to the solution of the present invention as described in the above embodiment, by adding salt powder that is insoluble in resin but soluble in water to the photocurable resin used for printing, after the material is printed and formed, the salt powder is di...

Embodiment 2

[0034] Chitosan was used as the particulate matter and water was used as the solvent.

[0035] 1) According to the design needs, batch production of chitosan particles with a particle size of 0.05mm as a "punched" granular material;

[0036] 2) Incorporating chitosan particles into the photocurable resin, and the volume ratio of the incorporated chitosan particles to the photocurable resin is greater than 50%;

[0037] 3) The light-curing resin doped with chitosan particles is printed and formed by a light-curing 3D printer;

[0038] 4) Put the printed object into water to dissolve the incorporated chitosan particles in the water;

[0039] 5) After dissolving, holes are formed in the original chitosan particles, and the holes are connected to form channels.

[0040] According to the solution of the present invention as described in the above embodiment, by adding chitosan, which is insoluble in resin but soluble in water, into the photocurable resin used for printing, after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com