Coating and preparation method thereof

A paint and coating technology, applied in the field of infrared camouflage paint and its preparation, can solve problems such as inability to realize visible light camouflage camouflage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

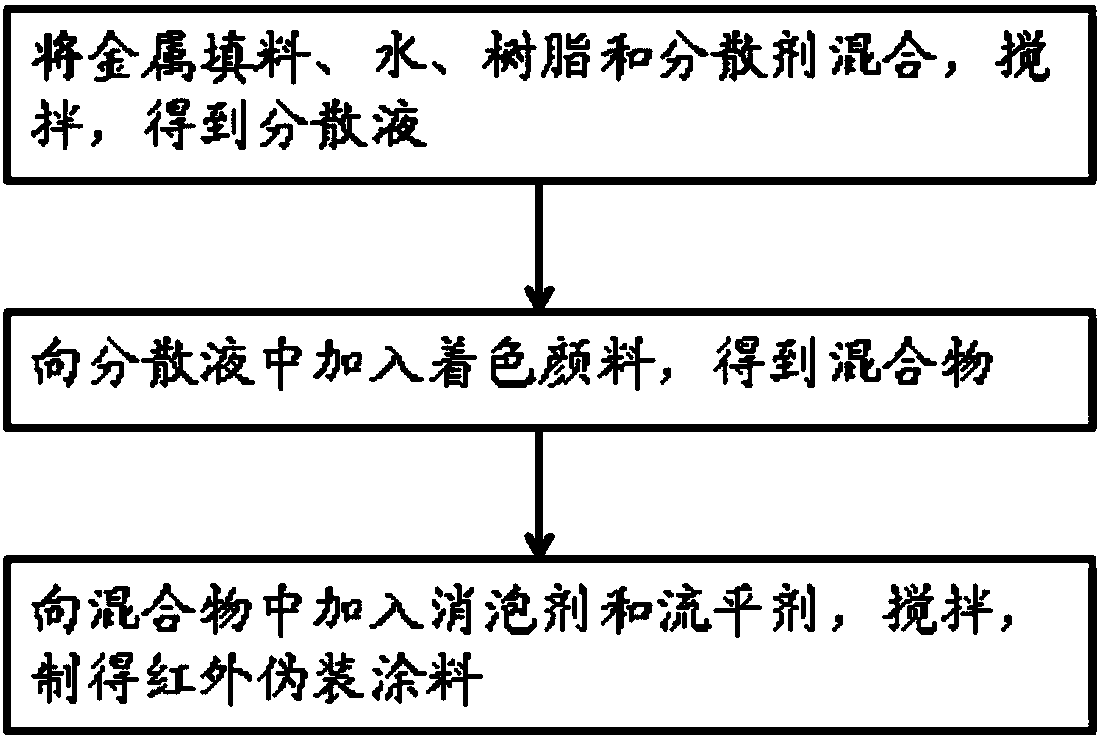

[0025] The preparation method of the coating that is used for infrared camouflage provided by the invention comprises the following steps:

[0026] like figure 1 As shown, the metal filler, water, resin and dispersant are mixed and stirred to obtain a dispersion. In this step, mix 1 to 8 parts of metal filler and 1 to 8 parts of water in parts by weight, stir well until the metal filler is evenly mixed in water, then add 0 to 3 parts of diatomaceous earth, stir evenly, and Add 8-15 parts of resin, 0.3-0.8 parts of dispersant, and stir at a speed of 100-200 rpm for 20-40 minutes to obtain a dispersion, wherein the weight ratio of metal filler to water is 1:1. In this step, the metal filler is a combination of one or more of aluminum silver paste, reduced iron powder, and copper powder, wherein the aluminum silver paste is a floating water-based aluminum silver paste; the water is deionized water; the resin is water-based Resin, the resin is a combination of one or more of wat...

Embodiment 1

[0031] In parts by weight, mix 1 part of floating-type water-based aluminum-silver paste with 1 part of deionized water, stir well until the floating-type water-based aluminum-silver paste is uniformly dispersed in deionized water, and then add 0.5 parts of diatomaceous earth, stir well, then add 8 parts of water-based polyurethane resin, 0.3 parts of sulfonate, stir at 100 rpm for 30 minutes to obtain a dispersion, add 1 part of green water-based color paste to the dispersion The coloring pigments are prepared into mixtures with different colors after being fully stirred, and finally 0.3 parts of polyoxypropylene glyceryl ether and 0.3 parts of diphenylpolysiloxane are added to the mixture to prepare a coating that can be used for infrared camouflage.

Embodiment 2

[0033] In parts by weight, mix 8 parts of floating-type water-based aluminum-silver paste with 8 parts of deionized water, stir well until the floating-type water-based aluminum-silver paste is uniformly dispersed in deionized water, and then add 3 parts of diatomite, stir evenly, then add 15 parts of water-based polyurethane resin, 0.8 part of sulfonate, stir at 200rpm for 25 minutes to obtain a dispersion, add 5 parts of green and black in different proportions to the dispersion The coloring pigment prepared by the water-based color paste, after being fully stirred, is blended into a mixture with different colors, and finally 0.8 parts of polyoxypropylene glyceryl ether and 0.8 parts of diphenyl polysiloxane are added to the mixture to obtain a color that can be used for infrared camouflage. coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com