Uniform anode oxidation process of cavity

An anodizing and cavity technology, applied in the field of cavity parts, can solve the problems of difficult to ensure the consistency of the long film of the inner and outer cavity, large size, and excessive film thickness of the outer cavity, so as to solve the problem of poor electrical conductivity and enhance the Resistance strength, the effect of enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

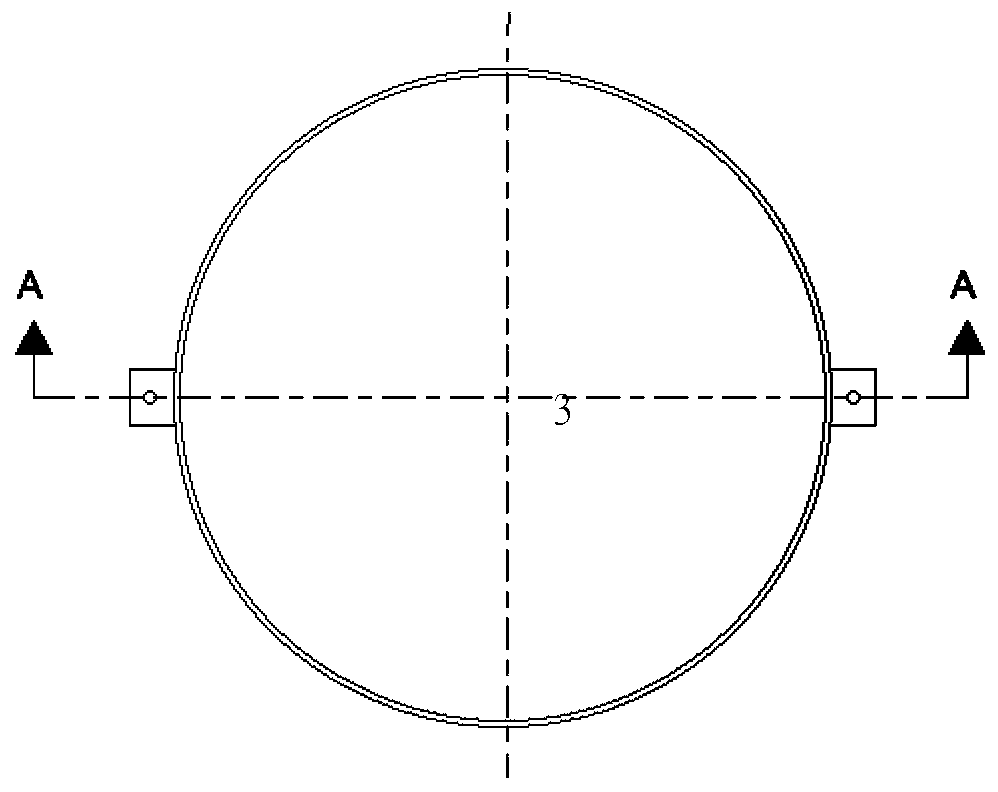

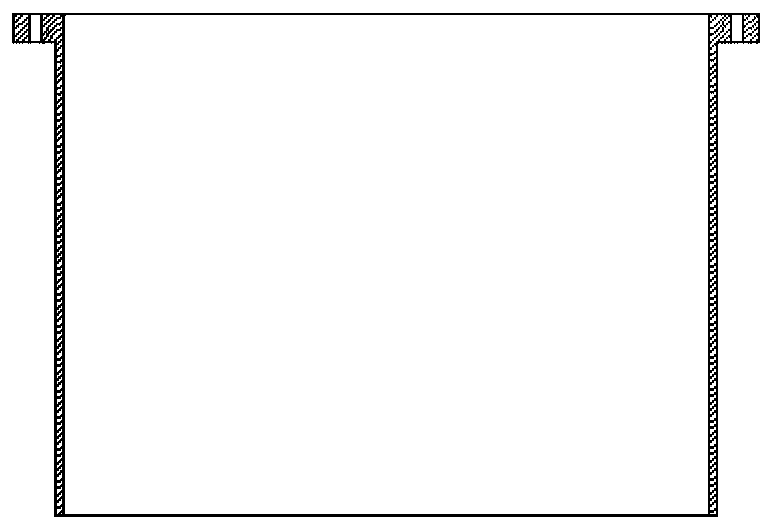

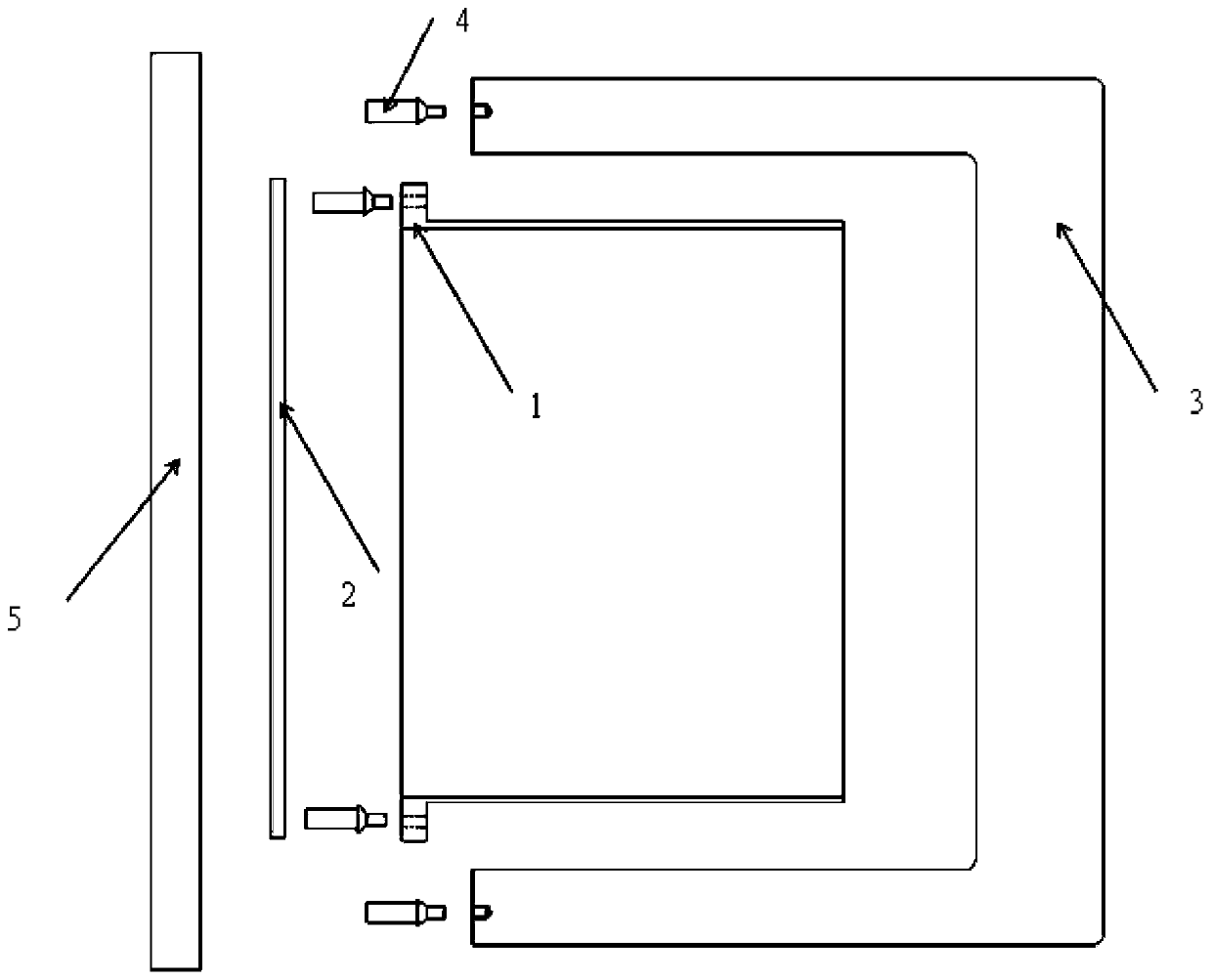

[0015] Such as image 3 As shown, the auxiliary cathode 1 is locked and fixed on the PP material rod 2 with the screw 4, and at the same time, the copper wire segment is locked with the screw, and the other end is reserved to connect with the cathode of the tank body; at the same time, the PP of the auxiliary cathode is connected The rod 2 is fastened to the titanium rod 5 by screw locking. Note that the auxiliary cathode 1 and the titanium rod 5 must be insulated and cannot be connected; then, adjust the position of the auxiliary cathode and put it into the cavity. The distance between the end of the auxiliary cathode and the bottom surface of the cavity is 40-50mm, and the cavity 3 and the titanium rod 5 are locked with the hanging screw 4; finally, the conductive connection between the cathode and the anode is normal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com