Phase-change thermal insulation wadding and preparation method thereof

A phase change and flake technology, applied in rayon manufacturing, textile and papermaking, single-component cellulose rayon, etc., can solve the problem of reducing the intelligent temperature regulation function of thermal flakes, poor air permeability and softness of thermal flakes , reduce the wearing comfort of thermal clothing and other issues, achieve the effect of overall lightness and softness, overall moisture conduction and quick drying, and ensure the intelligent temperature adjustment function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

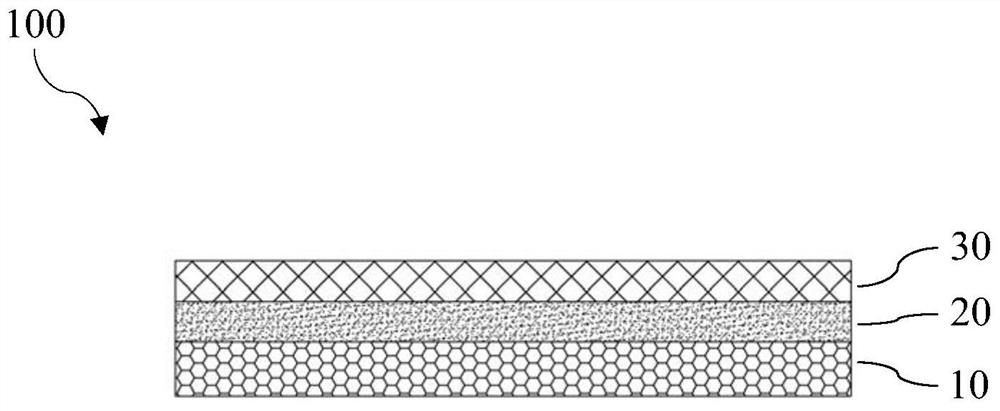

[0029] figure 1 It is a schematic diagram of the cross-sectional structure of the phase-change thermal insulation floc in an embodiment of the present invention.

[0030] Such as figure 1 As shown, the phase-change thermal insulation batt 100 in this embodiment includes a moisture-conducting fiber mesh layer 10 , a thermal storage fiber mesh layer 20 and a heat-insulating fiber mesh layer 30 arranged in sequence and connected to each other by non-woven needling. In this embodiment, the thickness of the phase-change thermal insulation wadding 100 is 0.3-0.5 mm, and the needle punching density is 20-30 punctures / cm 2 .

[0031] The moisture-conducting fiber net layer 10 is used for contacting with the human body, and is made of 55-80% of ordinary fibers, 15-35% of special-shaped hollow superfine fibers and 5-10% of crimped fibers. In this implementation, ordinary fibers are polyester fibers with a fineness of 1.2 to 1.5 dtex and a length of 30 to 40 mm, special-shaped hollow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com