Intelligent positioning pouring system for steel shell concrete

An intelligent positioning and concrete technology, applied in construction, water conservancy projects, artificial islands, etc., can solve the problems of negligent paralysis, large shrinkage of concrete, and high amount of cementitious materials, and achieves intelligent procedures, easy operation, sufficient bubble discharge, and the number of bubbles. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

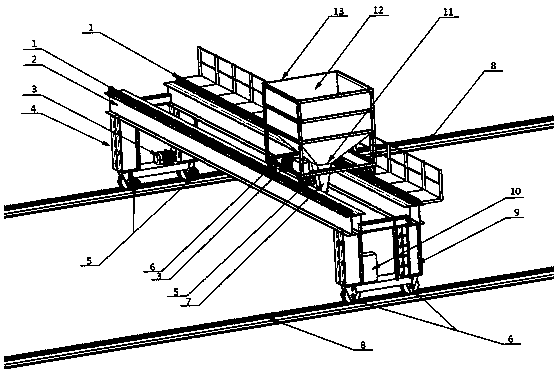

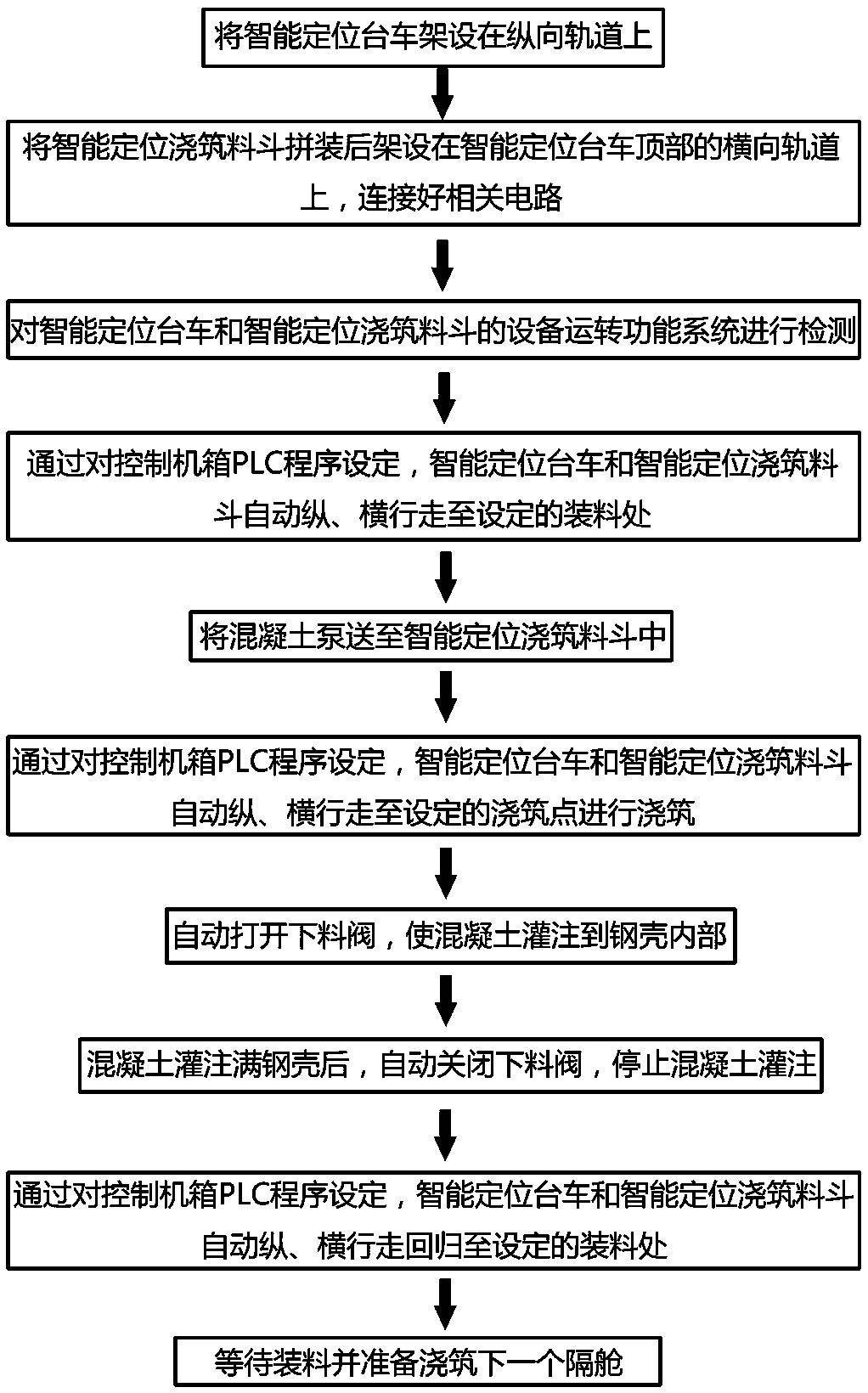

[0042] refer to figure 1 , figure 2 As shown, the intelligent positioning pouring system and method for steel shell concrete in an embodiment provided by the present invention includes an intelligent positioning trolley 4 , an intelligent positioning pouring hopper 13 , and a steel rail 1 . The intelligent positioning trolley 4 is erected above the 8 longitudinal rails, and the intelligent positioning pouring hopper 13 is erected above the horizontal rail 1 on the top of the intelligent positioning trolley 4;

[0043] Among them, the intelligent positioning trolley 4 includes the trolley frame (including the trolley beam 2 and the trolley leg 9), the control cabinet 10, the two-way wheel 6, the deceleration frequency converter 5 and the motor 3, and the control cabinet 10 is arranged on the trolley frame support. On the leg 9, four two-way wheels 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com