Start and stop control valve of high-pressure common rail oil injector

A high-pressure common rail and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve problems such as low power density, inability to reduce opening time and closing time, and inability to meet the matching requirements of high-efficiency and energy-saving diesel engines , to achieve the effect of reducing the turn-on delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

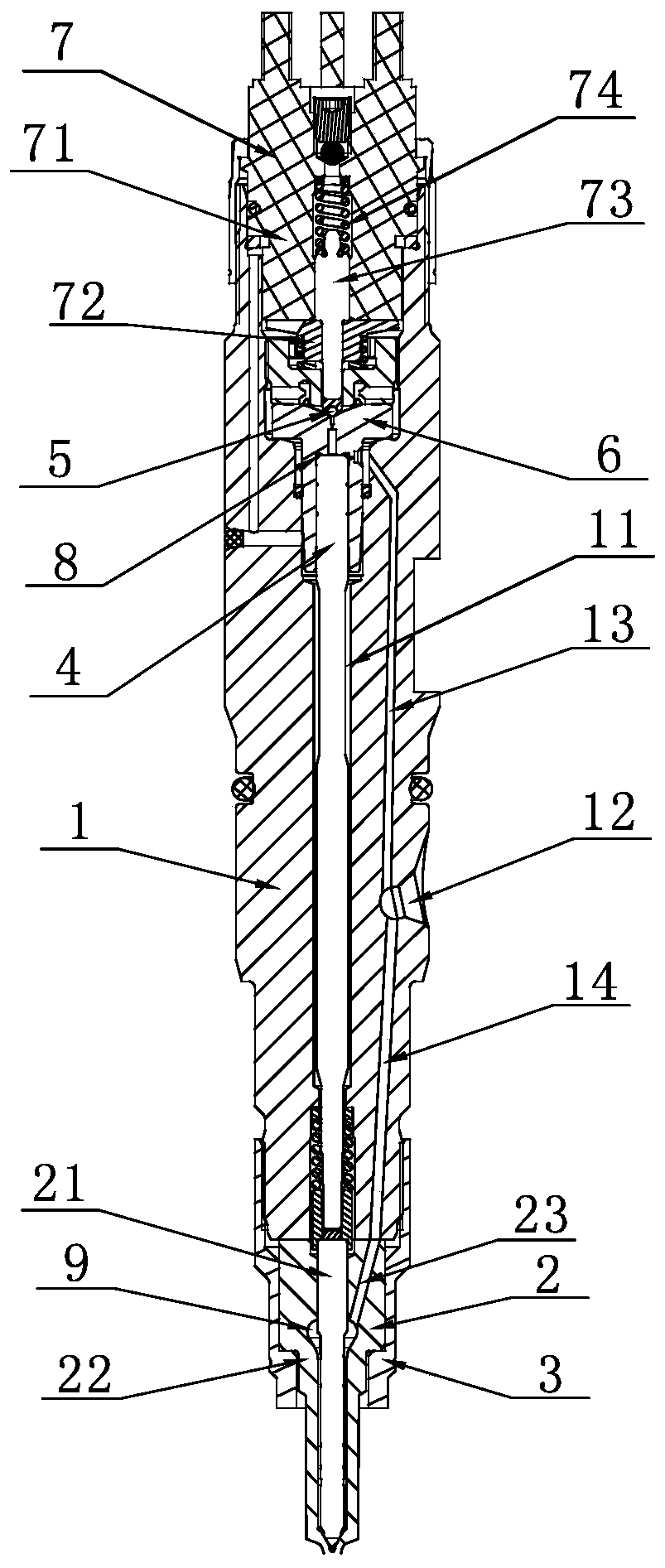

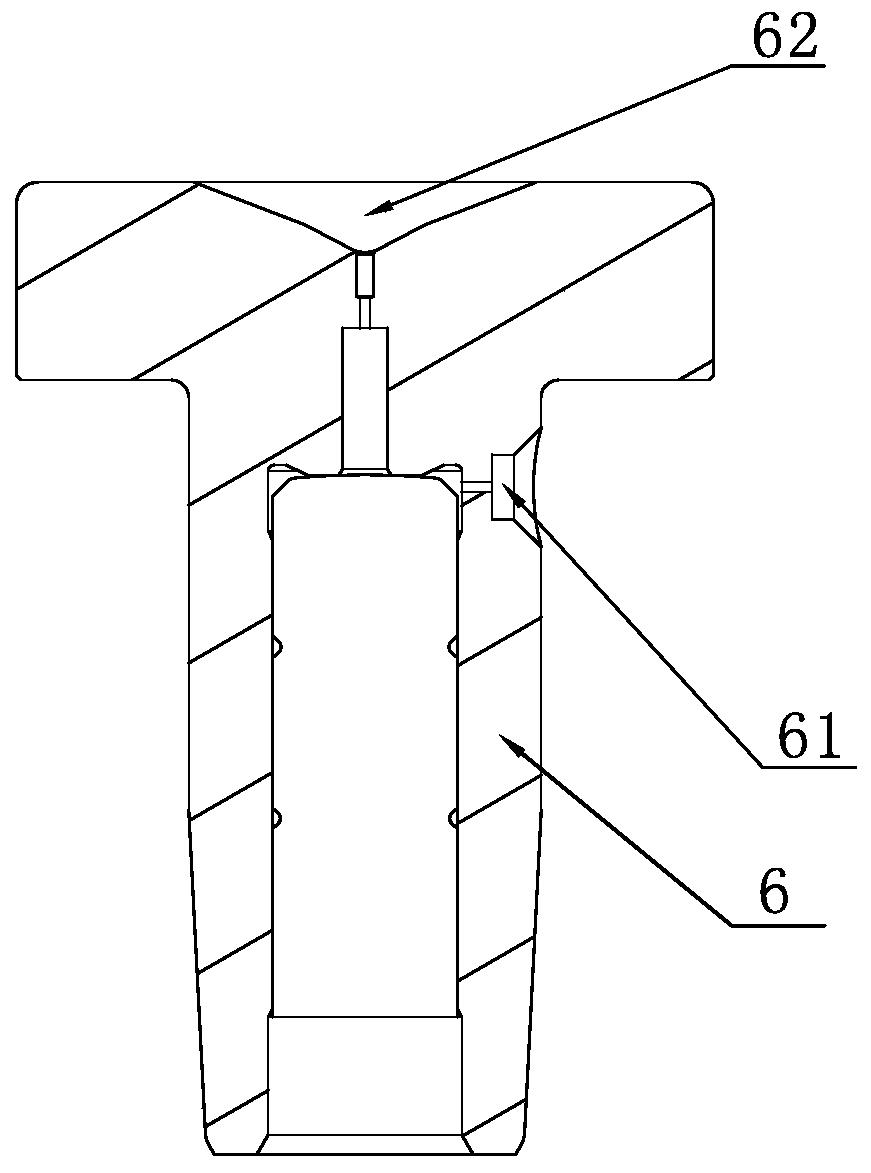

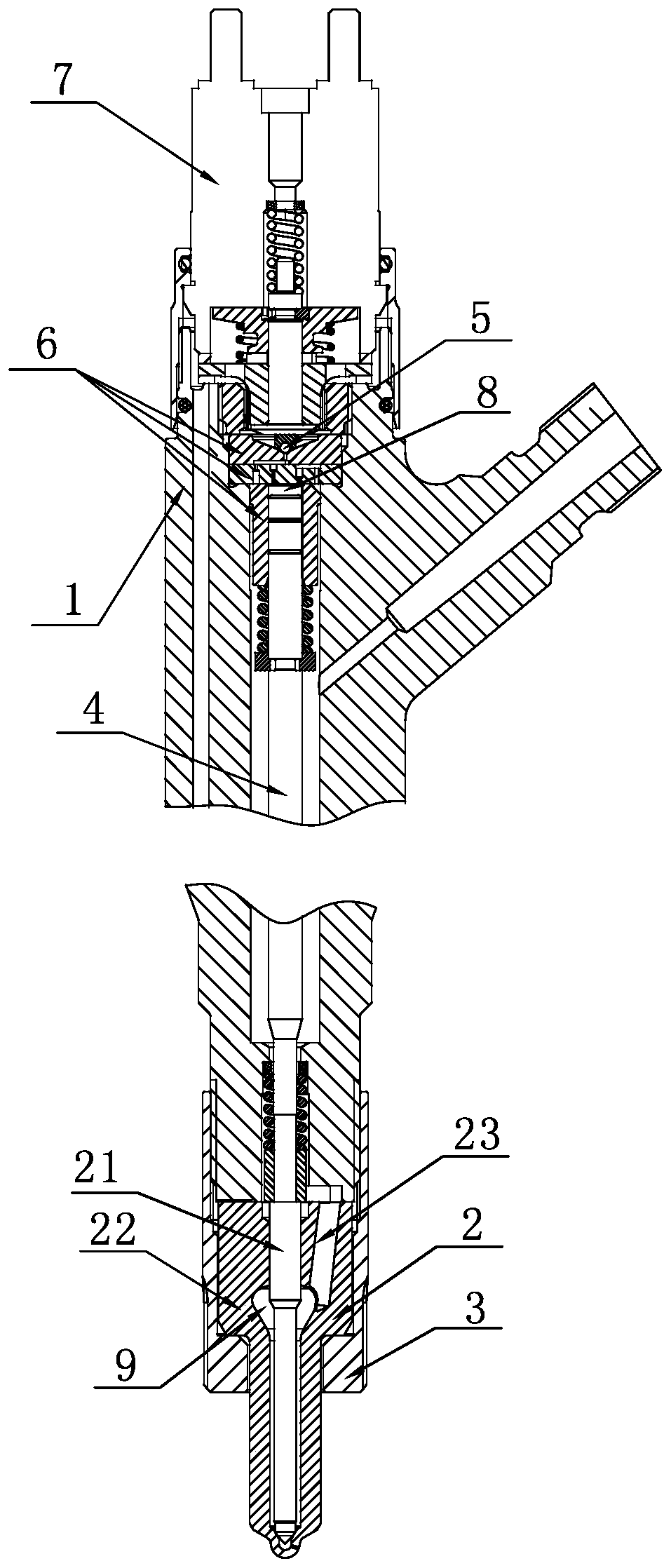

[0028] A high power density high pressure common rail injector such as Figure 3-Figure 9As shown, it includes valve body 1, fuel injection coupler 2, locking cap 3, valve stem 4, sealing ball 5, the present invention 6 and electromagnetic valve parts 7, and the present invention 6 includes valve seat 63, valve core 64 and oil inlet The guide valve sleeve 65, the valve seat 63, the valve core 64 and the oil inlet guide valve sleeve 65 are distributed coaxially from top to bottom in sequence, and the upper end surface of the valve seat 63 is provided with a tapered seat surface hole 631 and a vertical oil outlet hole 632 , the vertical oil outlet hole 632 is arranged in the center of the tapered seat surface hole 631, and an upper horizontal oil inlet groove 633 is arranged on the lower end surface, and the vertical oil outlet hole 632 communicates with the upper horizontal oil inlet groove 633; The oil inlet hole 641, the closed oil outlet hole 642, the lower horizontal oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com