Plate-fin type heat exchanger baffle spray-head structure sealing head

A plate-fin heat exchanger and head technology, which is applied to direct contact heat exchangers, heat exchanger types, heat exchanger shells, etc. Pressure drop increases and other problems, to achieve the effect of easy production and processing, reducing gas flow resistance, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing of description, but protection scope of the present invention is not limited thereto:

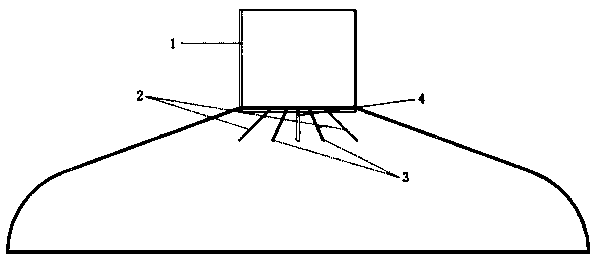

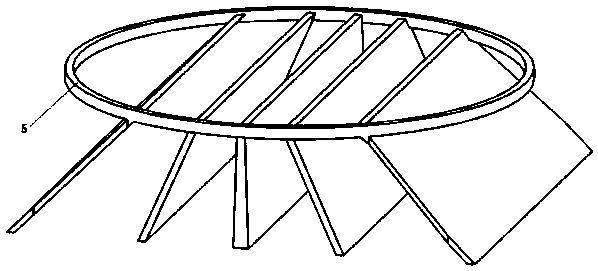

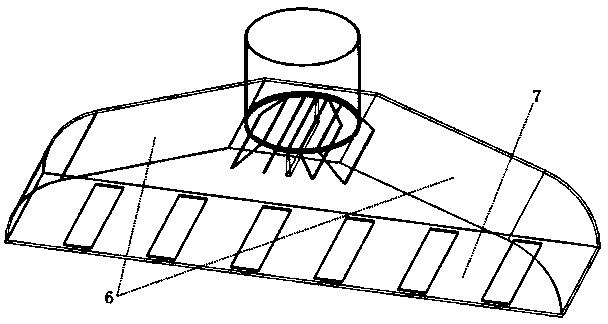

[0026] see Figure 1-3 , a plate-fin heat exchanger baffle nozzle structure head, including the head header 1, the baffle consisting of two baffles I2, two baffles II3, one baffle III4 and a welded ring 5 The nozzle structure, as well as the inclined square shell 6 and the outlet surface 7, the baffle I2, the baffle II3 and the baffle III4 in the baffle nozzle structure are connected with the ring 5 by welding, and then the ring 5 is connected to the main pipe of the head 1 end for solder connection.

[0027] The baffle I2 is arranged on both sides of the baffle III4, and the baffle II3 is arranged at a position between the baffle I2 and the baffle III4.

[0028] Among them, the angle range between the baffle I2 and the horizontal line is 40°-50°, the angle range between the baffle II3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com