A shock wave excitation device and method that affect the load-bearing deformation of filling materials due to mining

A technology of filling materials and impact of mining, which is applied in the direction of applying repeated force/pulsation force to test material strength, measuring device, vibration test, etc., and can solve the problems of load bearing impact, filling material block rotation, crushing, slipping, etc. , to achieve the effect of easy operation, wide practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below with reference to the accompanying drawings.

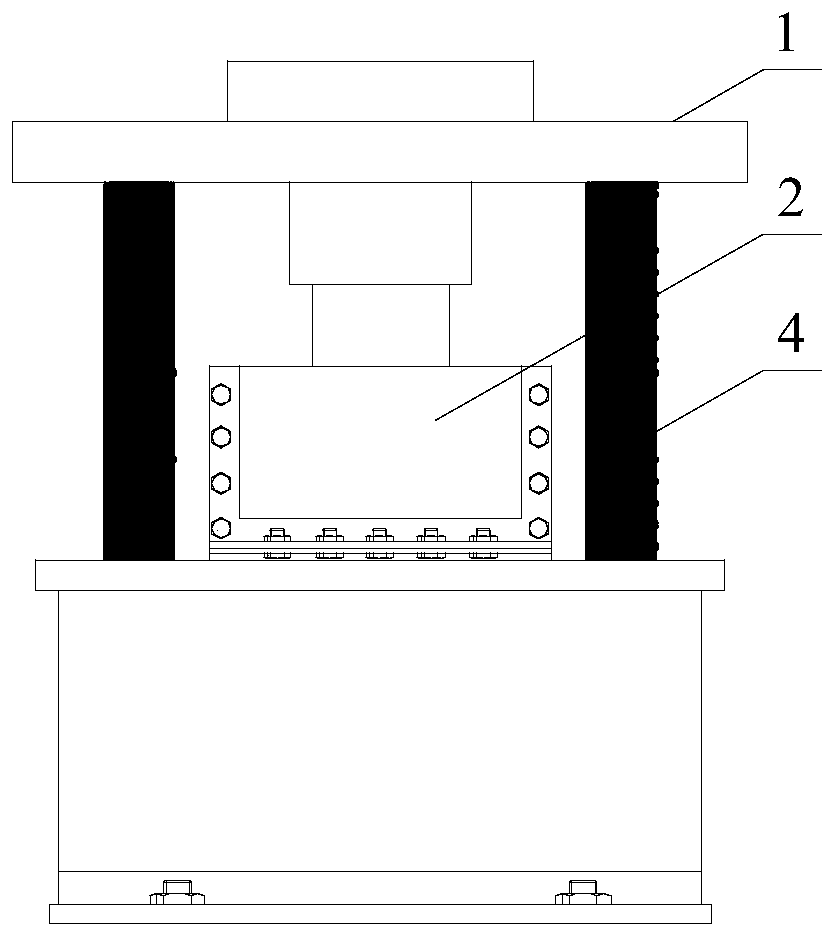

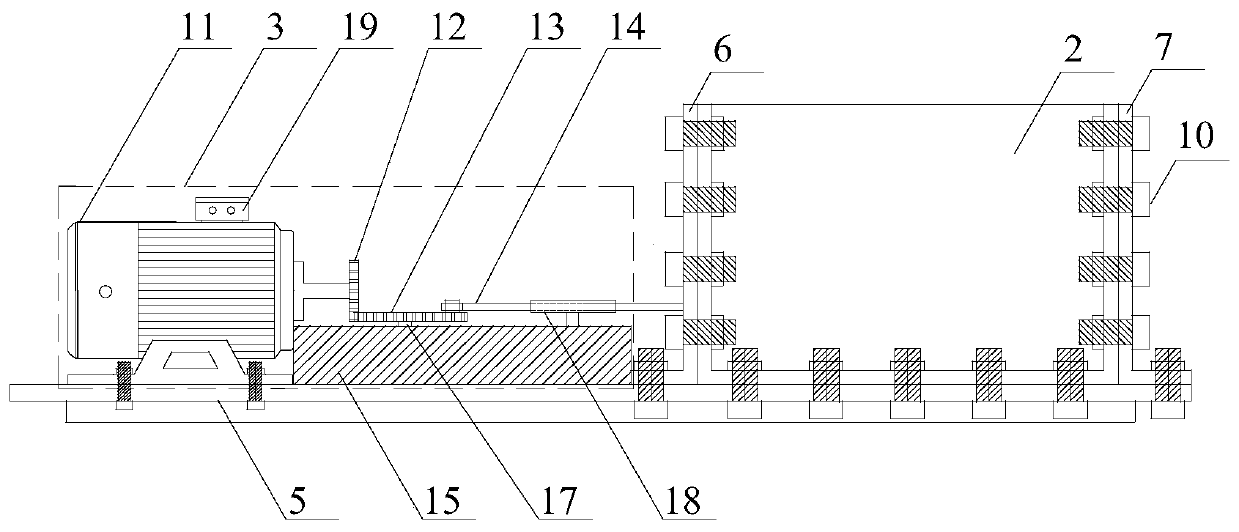

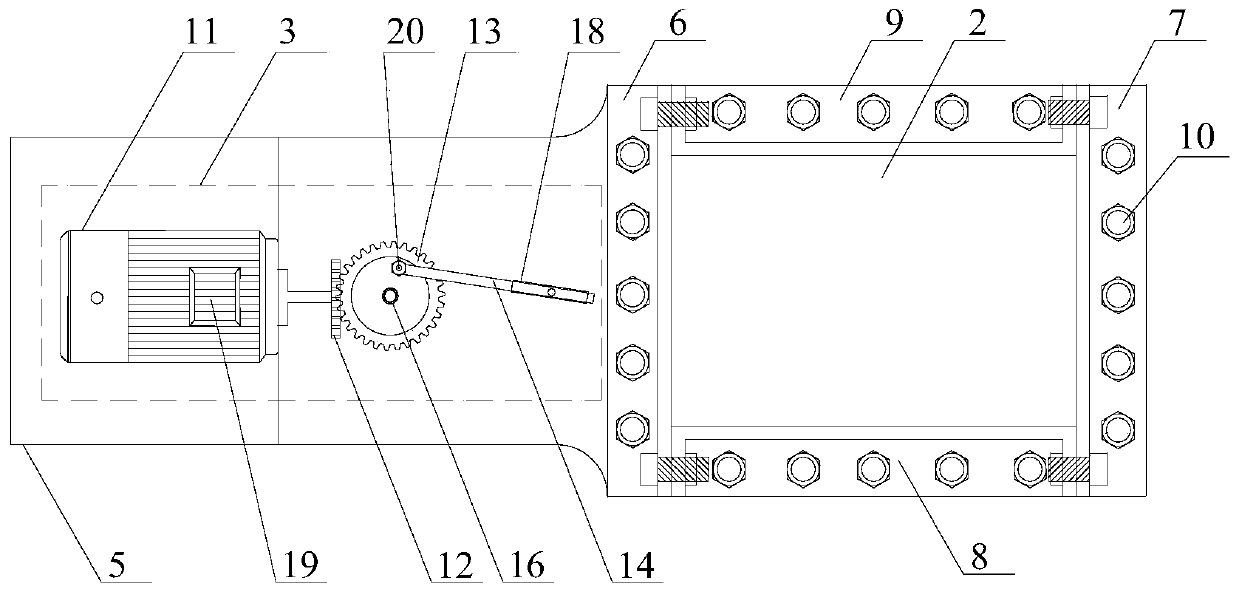

[0019] like figure 1 and figure 2 As shown in the figure, the shock wave excitation device of the present invention that affects the bearing deformation of the filling material is characterized in that: it comprises an axial loading device 1, a loading box 2 and a shock wave generating device 3, wherein the loading box 2 and the shock wave The generating devices 3 are respectively fixed on the rectangular metal base 5;

[0020] The axial loading device 1 is an electro-hydraulic servo universal testing machine 4, and the loading box 2 is placed on the electro-hydraulic servo universal testing machine 4, and axial loading is performed by the electro-hydraulic servo universal testing machine 4;

[0021] The loading box 2 includes a metal base 5 and a rectangular frame formed on four sides by a front side plate 6, a rear side plate 7, a left side plate 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com