Comprehensive detection method of composite insulator aging degree

A composite insulator and aging degree technology, which is applied in the measurement of electricity, measuring devices, measuring electrical variables, etc., can solve the problems of difficulty in judging the remaining life of composite insulators, and inability to judge long-term grid-connected operation, so as to ensure safe and reliable operation, The effect of precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments will now be described in detail, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following examples do not represent all implementations consistent with this application.

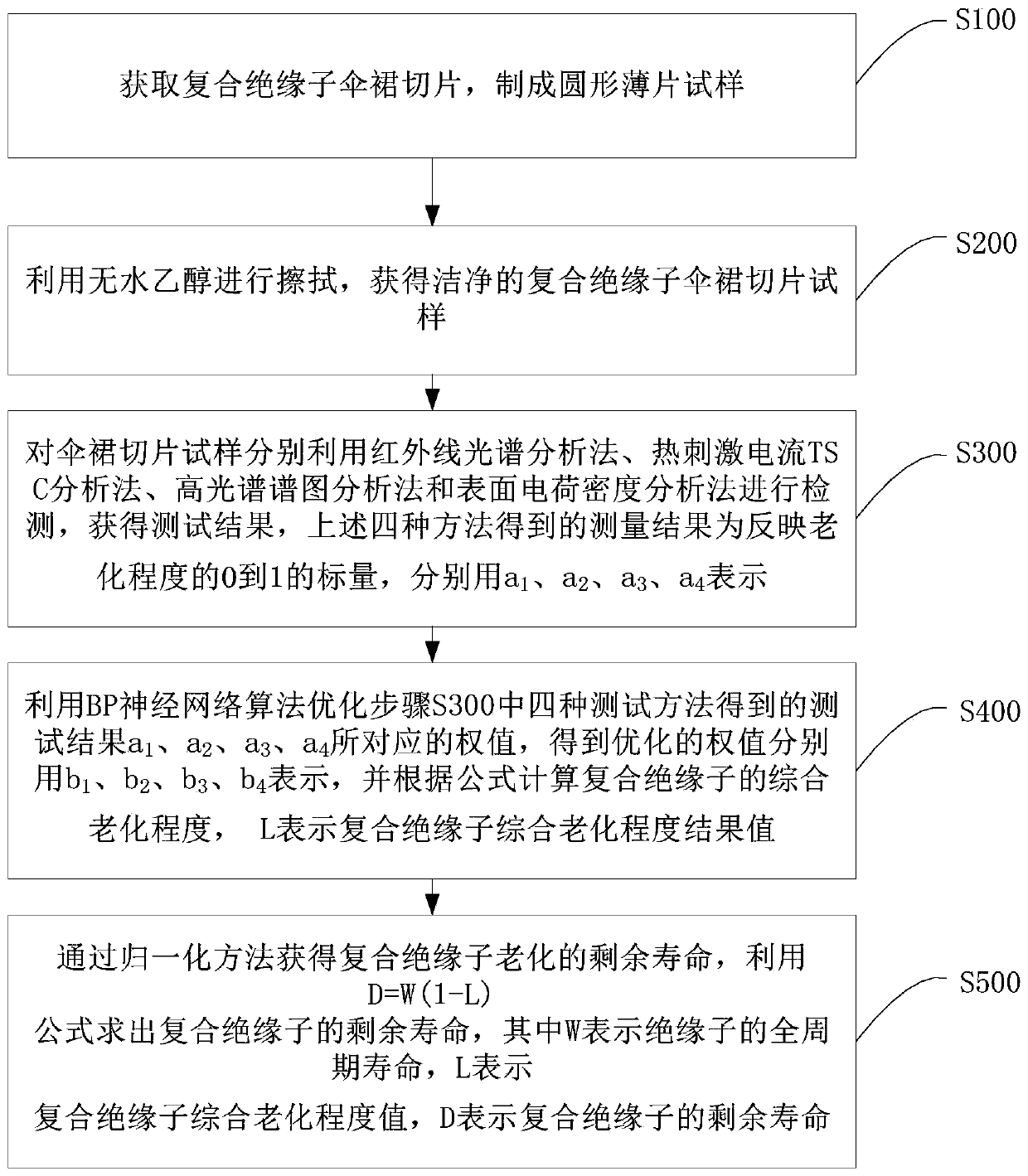

[0051] see figure 1 , which is a flowchart of a comprehensive detection method for the aging degree of composite insulators in this application.

[0052] A comprehensive detection method for the aging degree of composite insulators, said method comprising the following steps:

[0053] Step S100: Obtain slices of composite insulator sheds to make circular thin slice samples;

[0054] Step S200: Wipe with absolute ethanol to obtain a clean composite insulator shed slice sample;

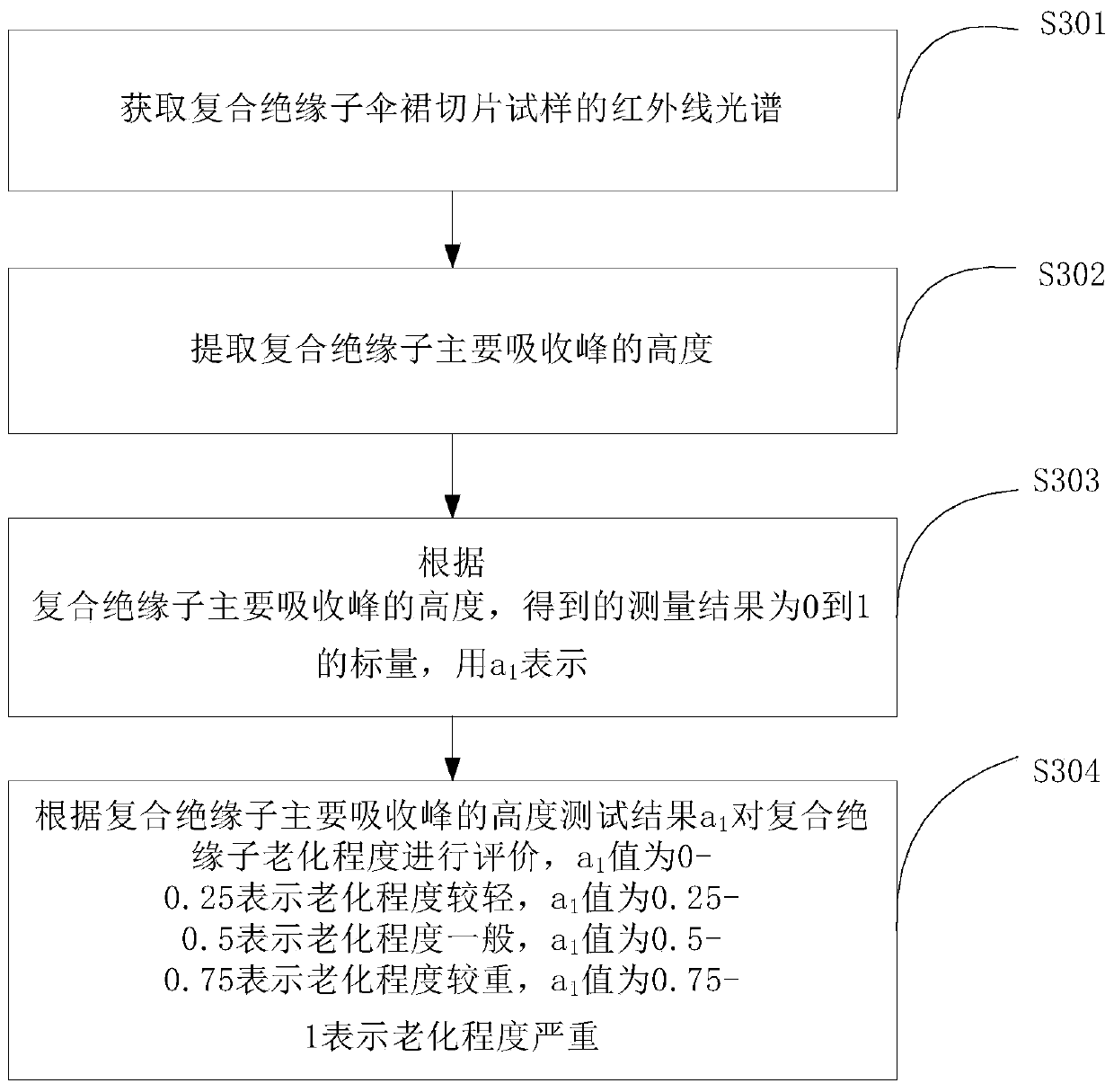

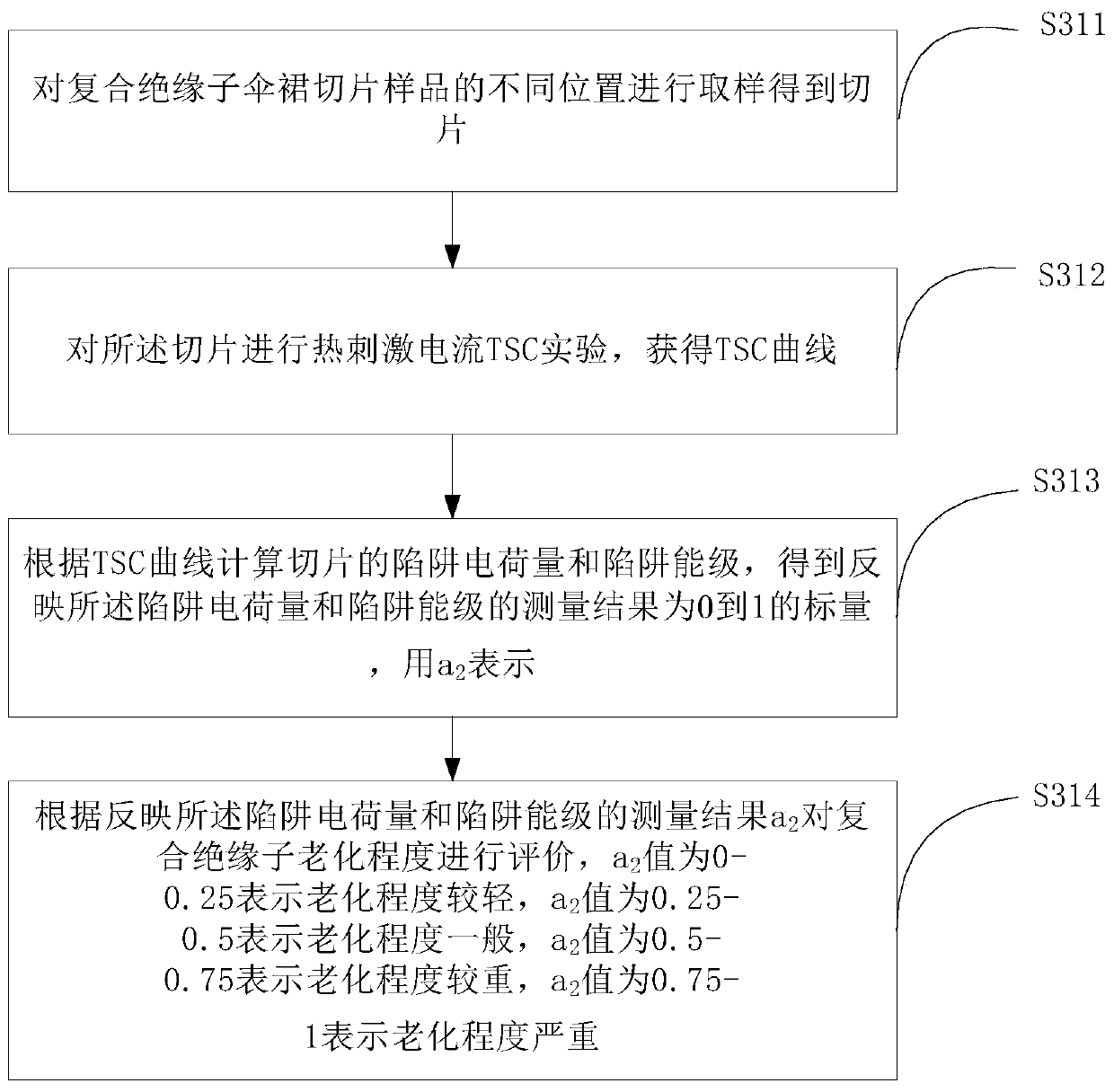

[0055] Step S300: Use infrared spectroscopy, thermal stimulation current TSC analysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com