Coordinating manipulator-based adaptive neural network synchronous robust controller design method

A robust controller and neural network technology, applied in the field of adaptive neural network synchronous robust controller, can solve problems such as uncertainties in the standard parameters of a manipulator base, and achieve the effects of reducing production costs and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation steps.

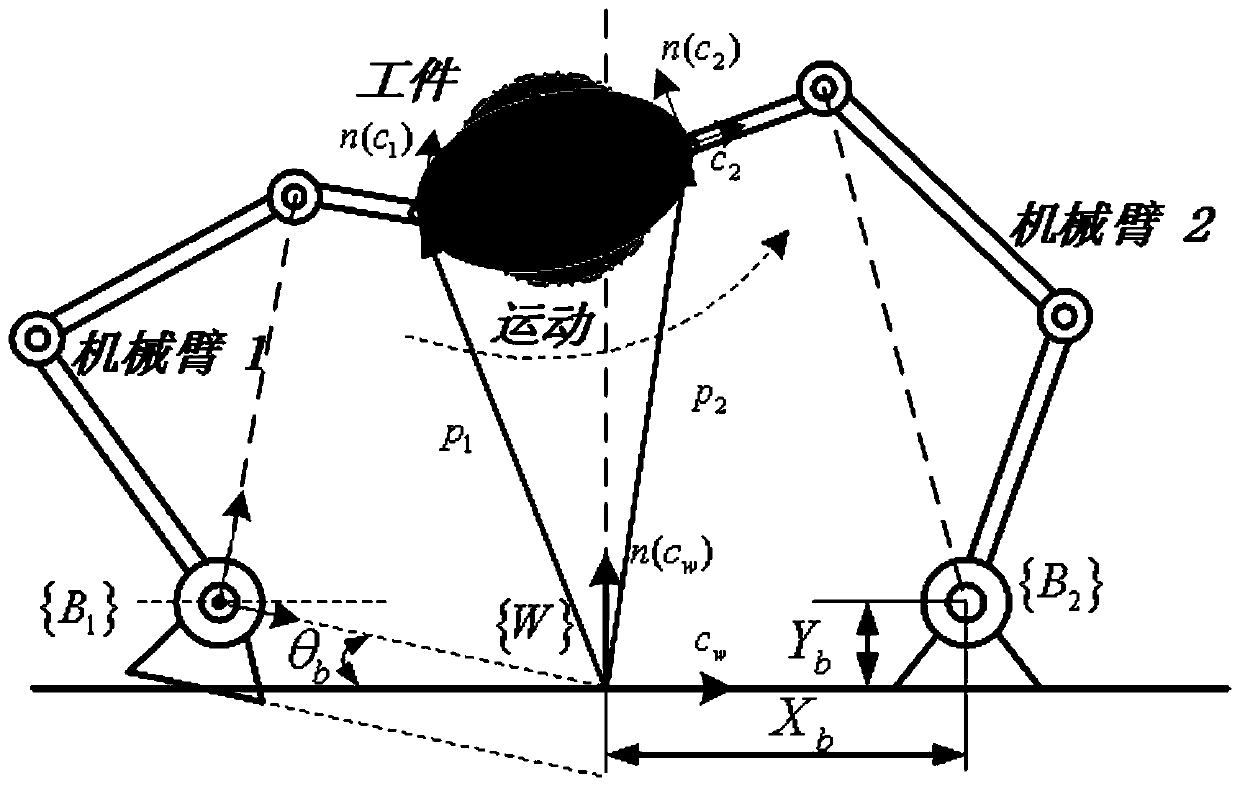

[0028] refer to figure 1 , select the scene of coordinated clamping of dual robotic arms to implement the technical solution. Both robotic arms are composed of three parallel degrees of freedom in the plane, which has certain redundancy. Such as figure 1 As shown, the mechanical arms on both sides have the same physical parameters, where the moment of inertia I of the connecting rod of the mechanical arm 1 = I 2 =0.5kg·m 2 , the mass of the connecting rod of the manipulator m 1 = m 2 = m 3 = 1.5kg, the length of the connecting rod l 1 = l 2 =0.6m,l 3 = 0.2m. The moment of inertia of the clamped workpiece is 0.3kg m 2 , the mass of the workpiece is 1.5kg, and the radius of the workpiece is 0.2m.

[0029] refer to figure 1 , the uncertain translation and angle parameters of the base mark are reflected in X b , Y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com