Thickener underflow concentration prediction method based on integrated learning

An integrated learning and concentration prediction technology, which is applied in the mining field, can solve problems such as inability to analyze and predict, inability to find underflow concentration in time, and unsatisfactory underflow concentration prediction effect, so as to improve generalization ability, fast training speed and high prediction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0042] The invention provides a thickener underflow concentration prediction method based on integrated learning.

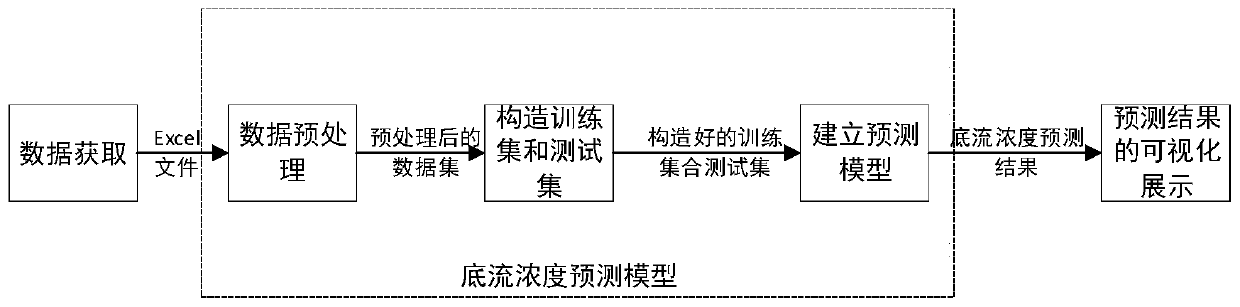

[0043] Such as figure 1 As shown, the method includes the following steps:

[0044] S1: Data Acquisition: Obtain actual production history data, which is recorded by the mine's automation system and stored in the enterprise database;

[0045] S2: Data preprocessing: Preprocess the data obtained in S1, remove irrelevant attributes, and then perform feature selection to obtain the preprocessed data set;

[0046] S3: Construct training set and test set: use the preprocessed data set in S2 to construct training set and test set;

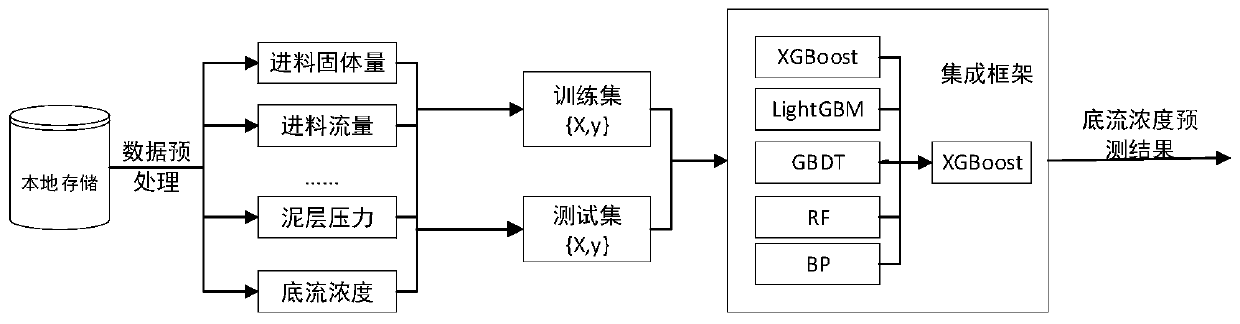

[0047] S4: Establish a prediction model: use the integrated learning method, use the training set and test set c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com