Frameless type electric reactor convenient to wind wire

A technology without skeleton and reactor, applied in transformer/inductor cooling, circuits, electrical components, etc., can solve the problems of increasing the cost of wire materials, reducing the heat dissipation area of the coil, increasing the surface heat load, etc., to increase the effective heat dissipation area. , Improve product consistency, improve the effect of winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

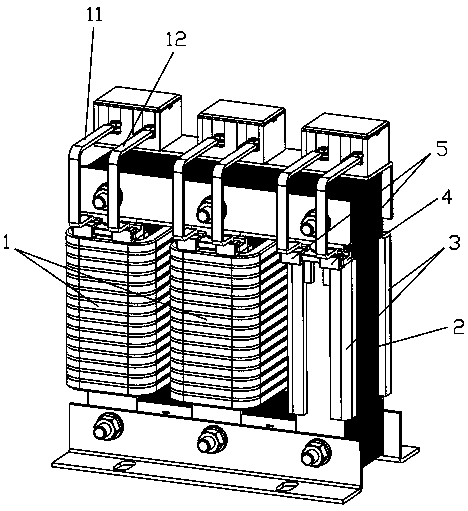

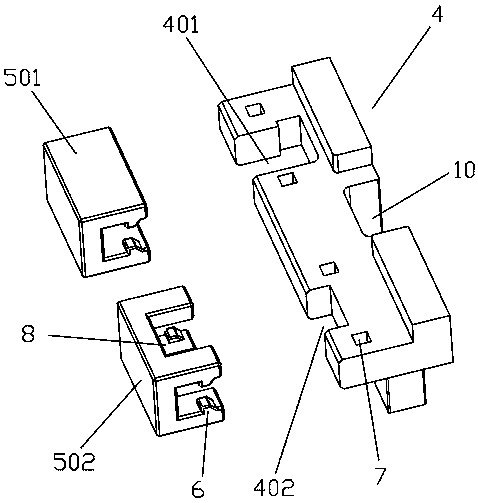

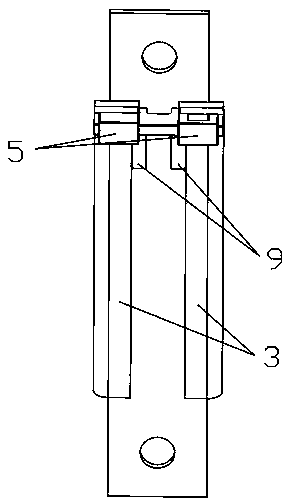

[0020] In the embodiment of the present invention, a frameless reactor that is convenient for winding includes a coil 1, an iron core 2, a winding stay 3 and a winding positioning module, and the winding stay 3 is evenly distributed on the iron The side surface of the core 2, the coil 1 is wound on the outer wall of the winding stay 3, the winding positioning module includes a positioning part 4 and a buckle 5, and the positioning part 4 is provided with a thread end groove 401 and thread tail groove 402 , the thread head and thread tail of the coil 1 are respectively placed in the thread head groove 401 and the thread tail groove 402 and locked by the buckle 5 .

[0021] Such as figure 1 As shown, the lead-out wire 11 of the incoming wire end is locked by the winding positioning module and the coil winding is started. After the winding is completed, the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com