Energy storage device

A device and energy storage technology, applied in the directions of hybrid capacitor terminals, hybrid boxes/casings/packages, etc., can solve the problems of increasing parts processing costs and testing costs, high processing accuracy requirements, and difficult processing, saving assembly time. , Improve production efficiency and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

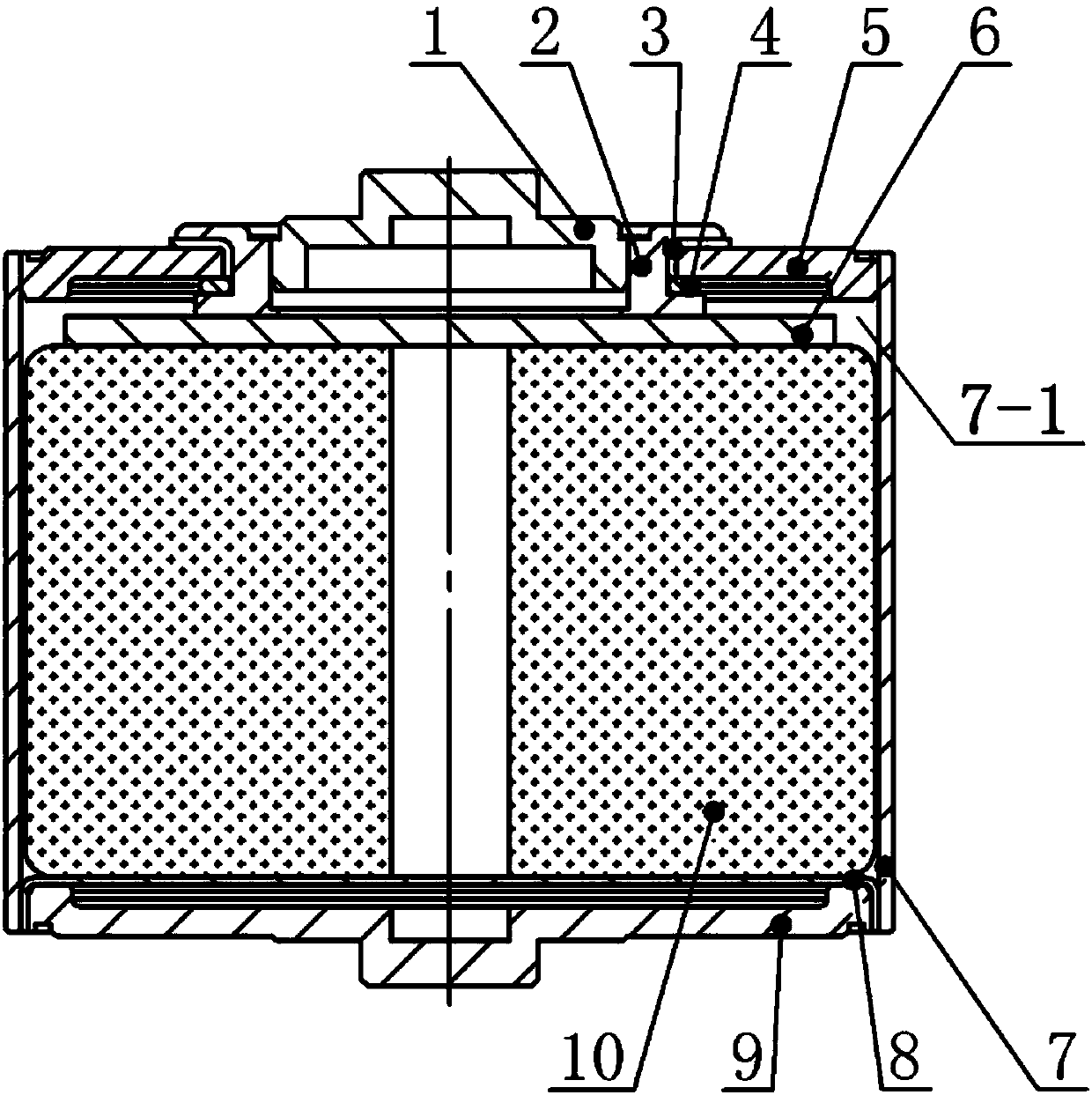

[0034] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

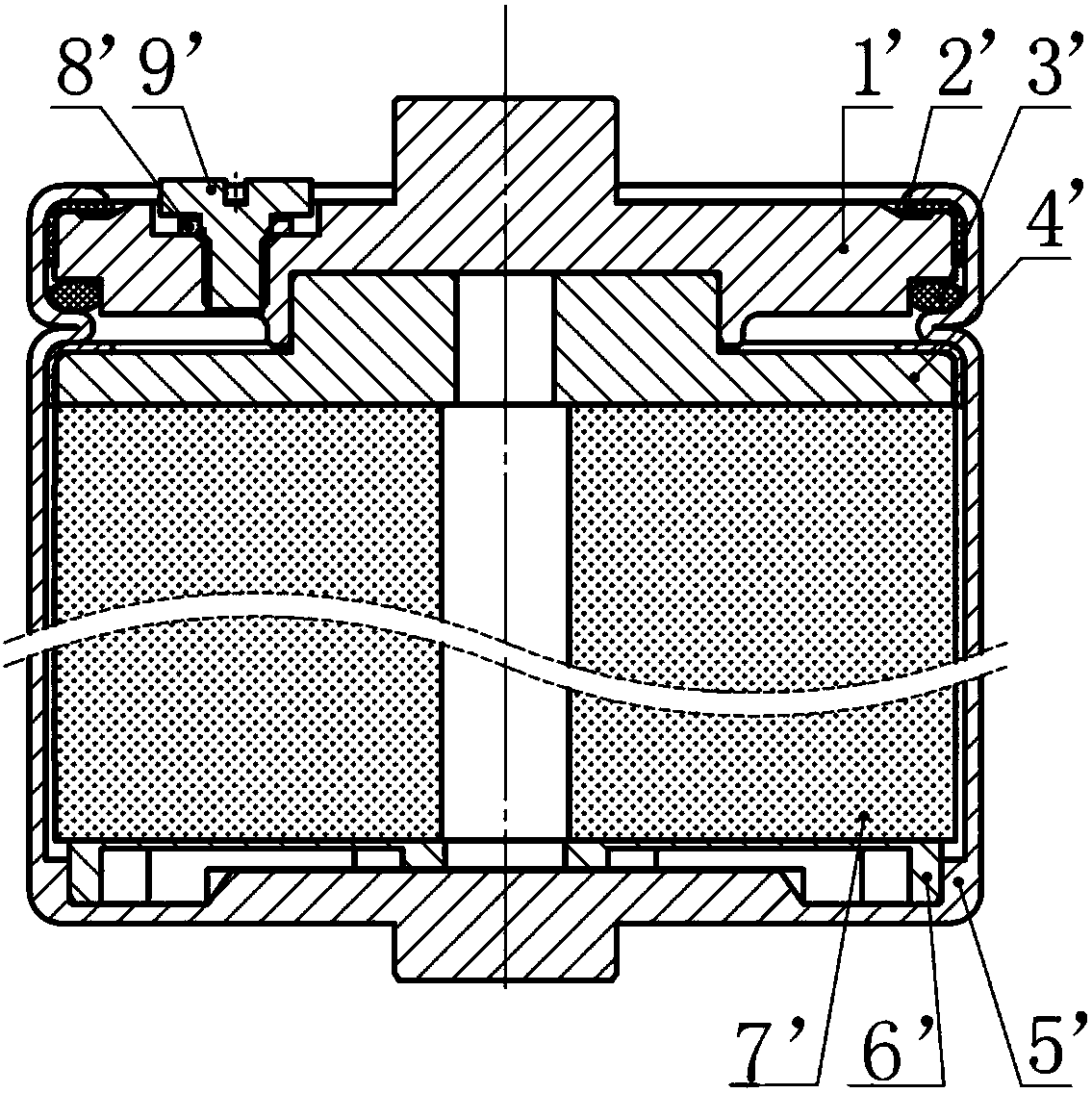

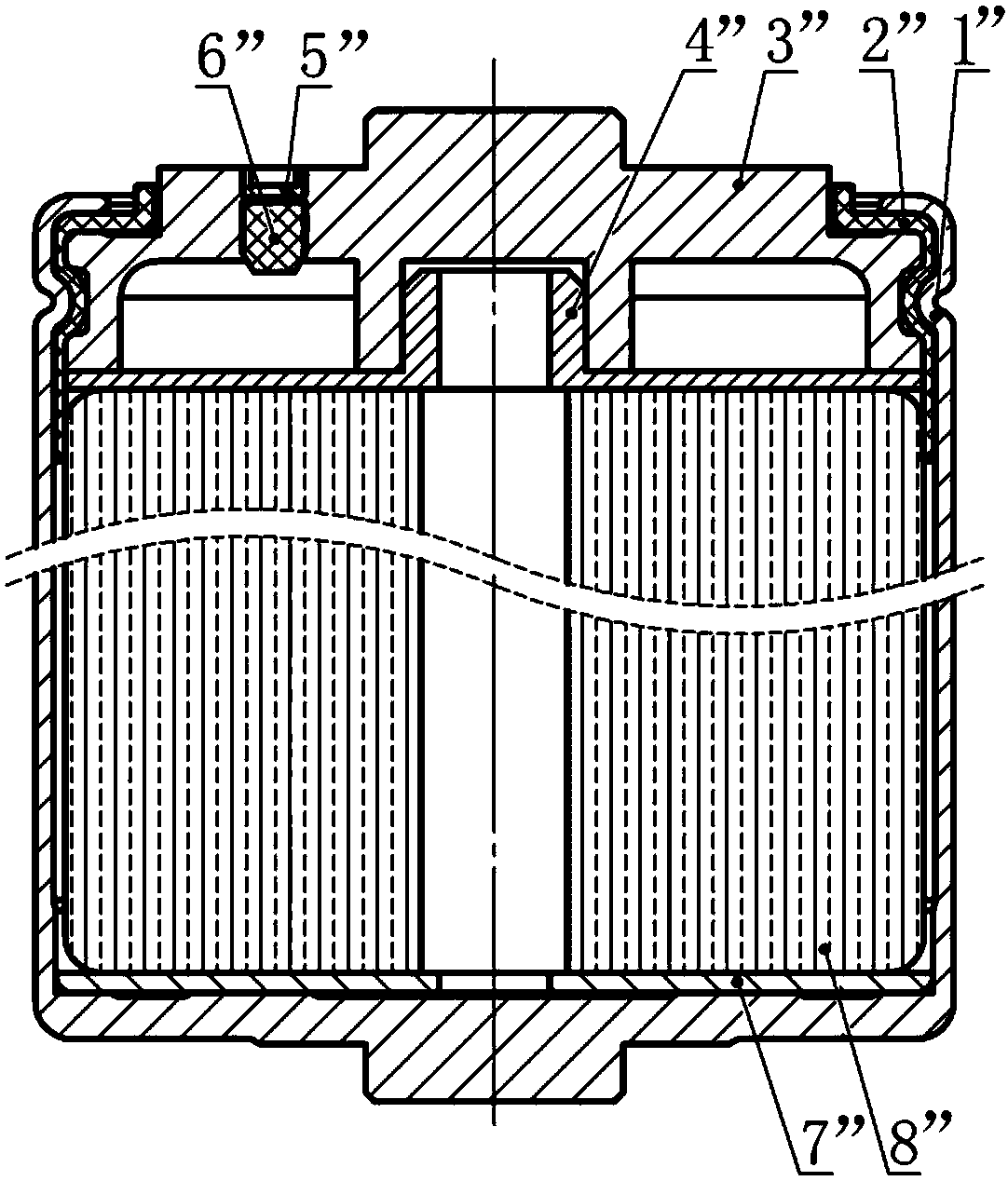

[0035] The present invention provides an energy device, such as Figure 3 to Figure 7 As shown, it includes a casing 7, a positive electrode lead-out structure, a core 10, a negative electrode cover 5 and a negative electrode lead-out structure, wherein:

[0036] The end of the casing 7 is provided with a first through hole 7-1, and the positive electrode lead-out structure, the core body 10 and the negative electrode cover 5 are sequentially sleeved in the first through hole 7-1 from the lower end of the casing 7;

[0037] The positive electrode lead-out structure includes a current collector 8 connected to the core 10 and a positive lead-out cover 9. The end of the current collector 8 is provided with a blind hole 8-1. In a through hole 7-1, the lead-ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com