Allulose-containing carbonated water and preparation method therefor

A technique of allulose and carbonated water, applied in the field of carbonated water and its preparation, can solve the problems of poor sensory properties and poor taste, and achieve the effects of reducing astringency, improving taste, and improving consumer preference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0036] Preparation Example 1: Preparation of Carbonated Water

[0037] Add liquid allulose (CJ CheilJedang, allulose with a dry solid content of 95% or more) or granulated sugar (CJ CheilJedang, white sugar) in the amount listed in Table 1, and then use magnetic stirring Stir for 30 minutes. After cooling the resulting mixture to 5°C, a maximum amount of carbon dioxide was injected into 1 L of the cooled mixture using a carbon dioxide injector (Delight Soda Chef, including injection container / Zahm & Nagel #9000-R PILOT PLANT), thereby preparing Comparative Examples 2 to 6 and the carbonated water samples of Examples 1 to 5. The carbonated water sample of Comparative Example 1 was prepared by injecting carbon dioxide in the same manner as in Comparative Examples 2 to 6 and Examples without adding psicose or granulated sugar. Each of the prepared carbonated water samples was filled into a pressure-resistant PET bottle and then sealed, and then stored in a refrigerator (5° C.)....

experiment example 1

[0040] Experimental Example 1: Sensory properties of carbonated water containing psicose

[0041] The sensory evaluation of each sample was performed by 30 panelists checking the sensory properties (astringency, sweetness, overall preference) of each sample of Examples 1 to 5 and Comparative Examples 1 to 6. In the sensory evaluation, each carbonated water sample was poured into tasting glasses with a random number to eliminate preconceptions, and then evaluated on a 9-point scale. The statistical analysis of the measurements was performed by analysis of variance (ANOVA), followed by post-testing by Duncan's multiple range test to analyze the significance of the storage time correlation.

[0042] The results confirmed that the carbonated water samples of Examples 1 to 5 had similar sweetness to the carbonated water samples of Comparative Examples 2 to 6, and exhibited significantly reduced off-flavor / odor intensity, and significantly improved cooling sensation and overall pref...

experiment example 2

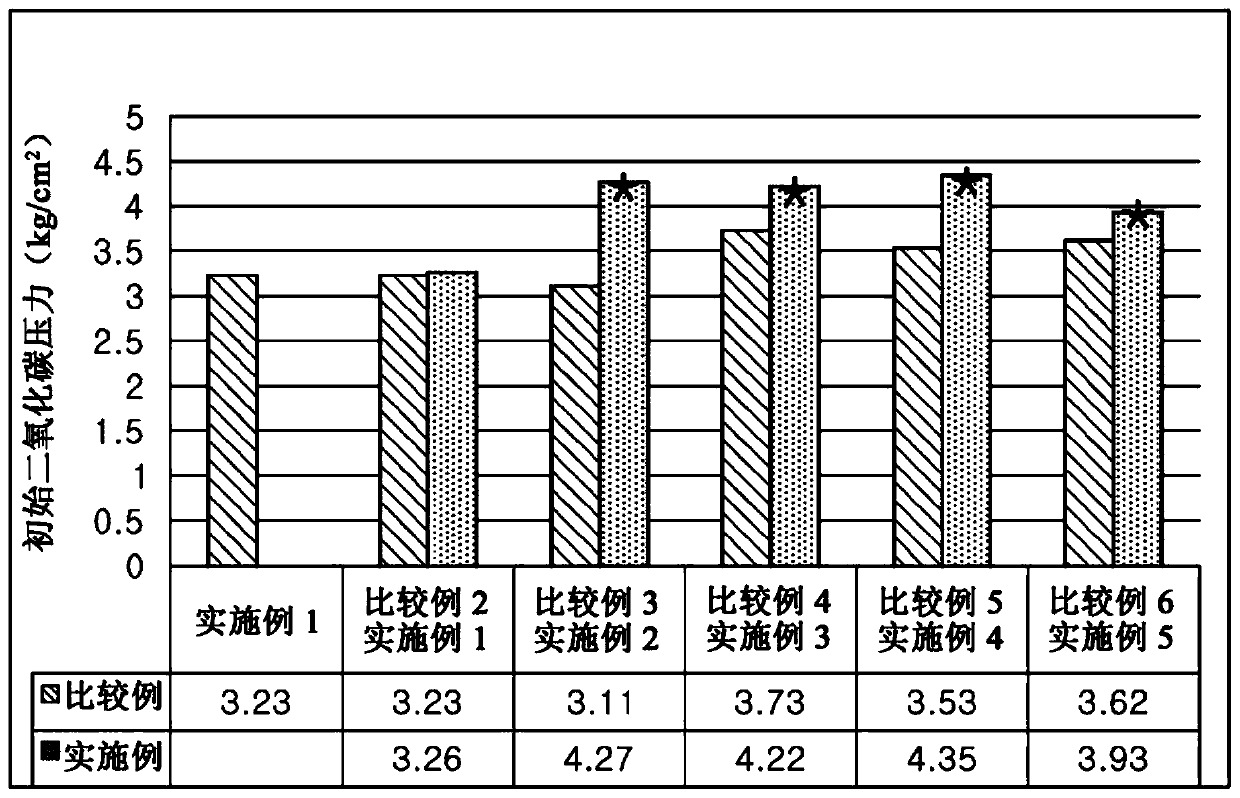

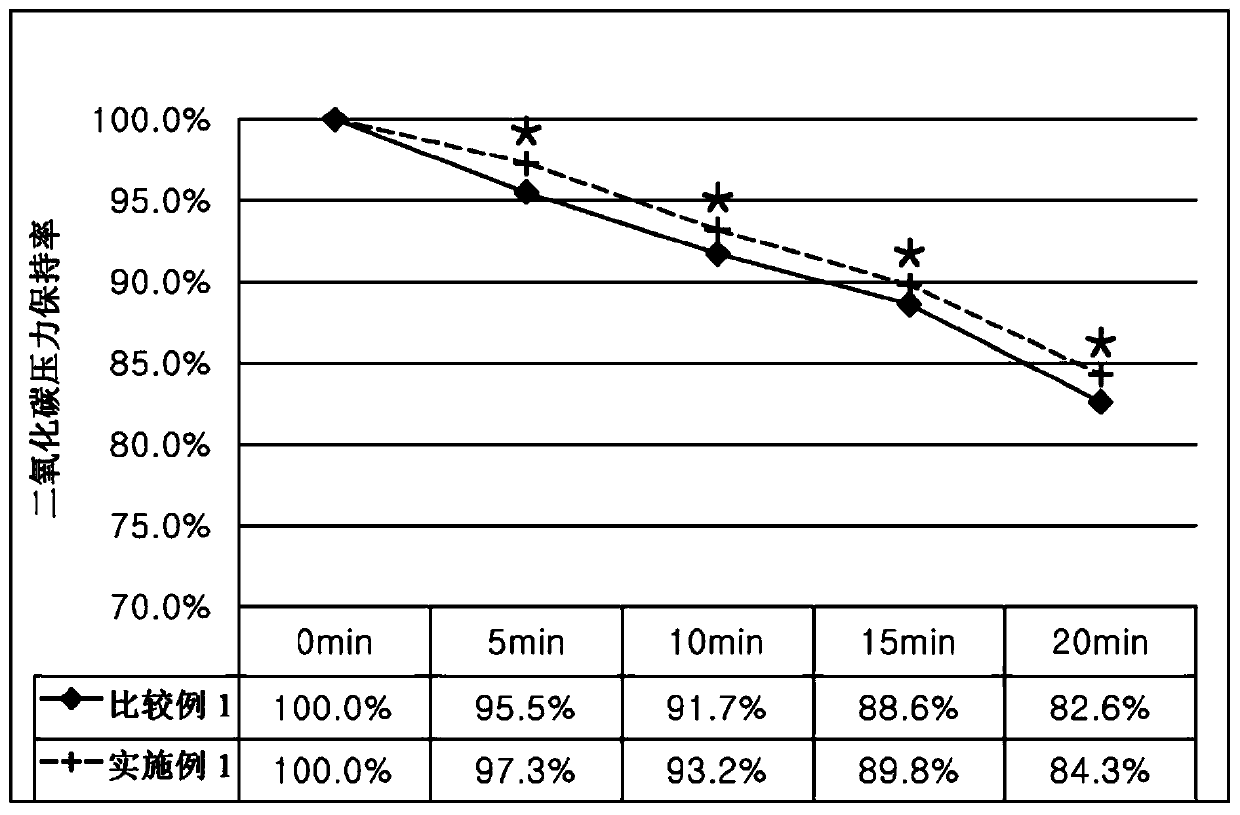

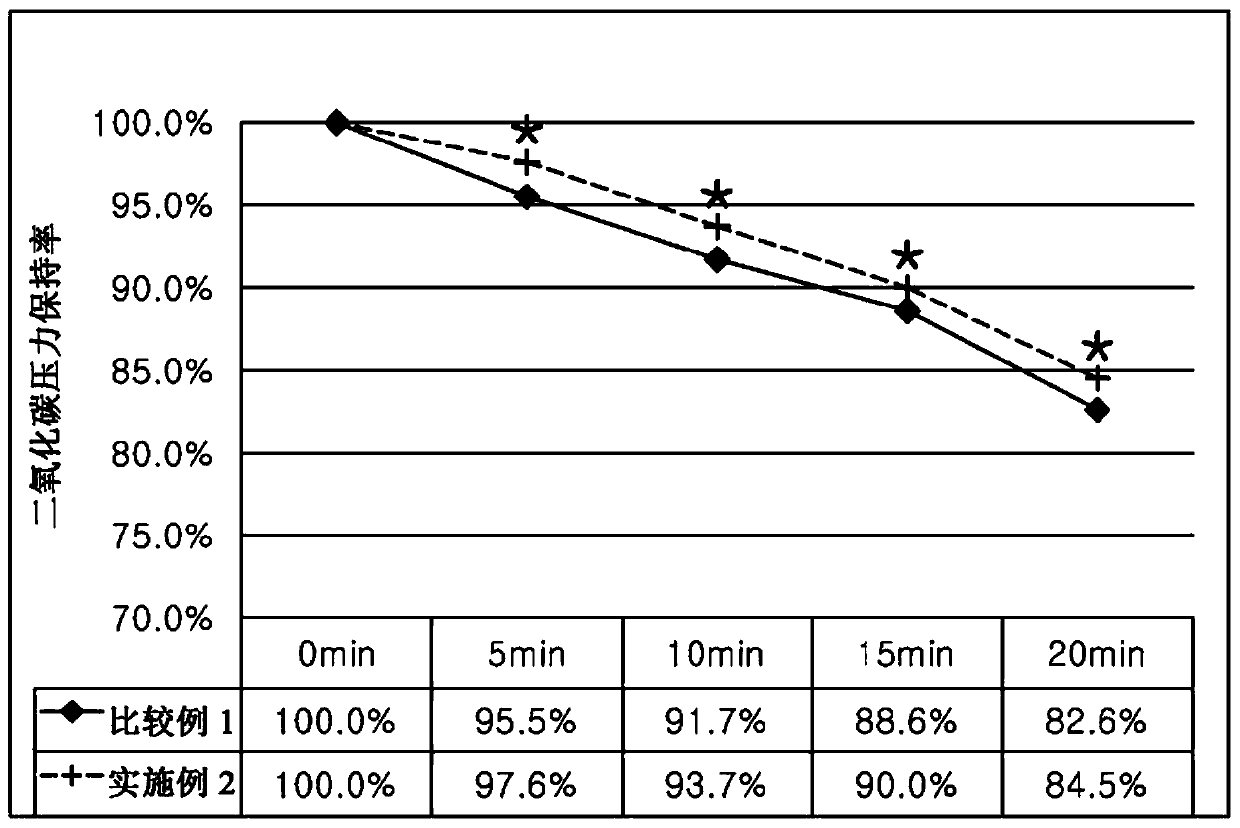

[0054] Experimental example 2: Carbon dioxide solubility and carbon dioxide pressure retention rate of carbonated water containing allulose

[0055] 2-1. Carbon dioxide solubility

[0056] The initial carbon dioxide pressure of each of the carbonated water samples of Examples 1 to 5 and Comparative Examples 1 to 6 prepared in Preparation Example 1 was measured to determine the solubility of carbon dioxide. Specifically, the initial carbon dioxide pressure was measured three times using a carbon dioxide manometer (6000 series, Zahm & Nagel Co., Inc.) according to the gas pressure test specified in the Korean Food Code (Section 18-2.(1), 2016).

[0057] The results confirmed that, compared with the carbonated water samples of Comparative Examples 1 to 6, the carbonated water samples of Examples 2 to 5 had significantly higher initial carbon dioxide pressures. Therefore, it can be seen that the carbonated water containing psicose according to the present invention has show a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com