warp knitted fabric

A warp knitted fabric and weave technology, applied in the directions of warp knitting, knitting, decorative textiles, etc., can solve the problems such as no clothes found, no disclosed embodiments of interwoven cellulose fibers and elastic yarns, and knitted fabrics are prone to curling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

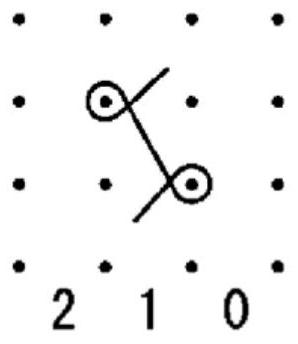

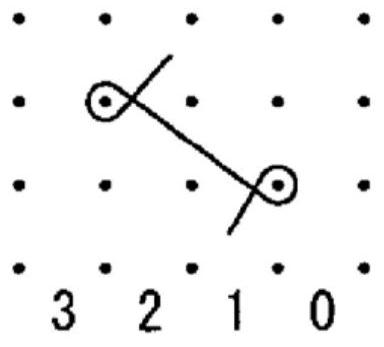

[0102] Using a 28-gauge tricot machine, nylon 33dt / 24 filaments are stretched and warped 100% on the front bar, and cupro fibers (trade name bemberg: manufactured by Asahi Kasei Co., Ltd.) are drawn on the middle bar. 33dt / 24 filaments are 100% elongated and warped, elastic yarn 44dt (trade name ROICA CR: manufactured by Asahi Kasei Co., Ltd.) is 100% elongated and warped on the rear bar, and all 3 bars are stretched toward the entire bar. threading, front bar with figure 2 The needle weave shown is woven, and the middle bar is figure 1 Warp weave shown, rear bar ends with Figure 8 The organization shown is organized.

[0103] Front Bar: Tissue 10 / 23 / /

[0104] Middle bar: Tissue 10 / 12 / /

[0105] Rear Bar: Organization 10 / 12 / 10 / 23 / 21 / 23 / /

[0106] The knitted fabric was relaxed and refined by a continuous refiner, and then pre-set at 190° C. for 1 minute, and nylon and cellulose fibers were dyed by a flow dyeing machine. Fill softening agent after dyeing, under the c...

Embodiment 2~5、 comparative example 1

[0108] In embodiment 1, change the tissue of the elastic yarn of rear part bar, produce the braid (embodiment 2: Figure 4 , Example 3: Figure 5 , Example 4: Image 6 , Example 5: Figure 7 ), in addition, a braided fabric (comparative example 1) was manufactured with the structure of the rear bar as 12 / 10 / / . The properties of the prepared braids were evaluated. The results are shown in Table 1 below.

[0109] The warp knitted fabrics obtained in Examples 2 to 5 do not cause curling at the cut portion of the knitted fabric, and can be made into products without processing after cutting, and the cool feeling, elongation, wearing feeling, and sewing process Sex is also excellent.

Embodiment 6

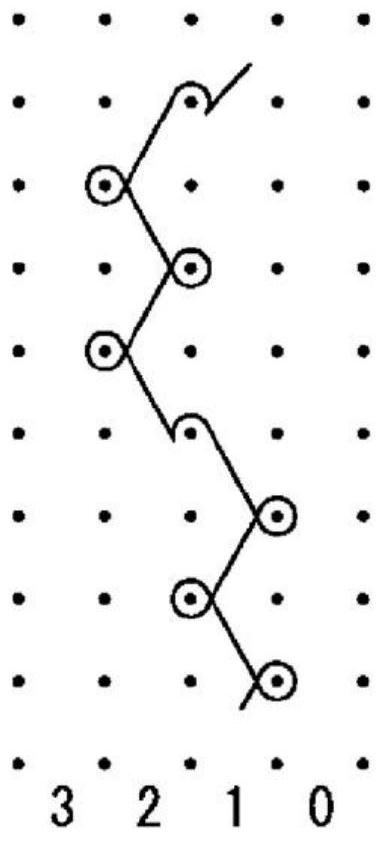

[0111] Using a Tricot warp knitting machine with a gauge of 32, the polyester 22dt / 6 filaments are 100% elongated and warped on the front bar, and the cupro (trade name bemberg: manufactured by Asahi Kasei Co., Ltd.) is warped on the middle bar. ) 33dt / 24 filament 100% elongated and warped, elastic yarn 22dt (trade name ROICA SF: manufactured by Asahi Kasei Co., Ltd.) is elongated and warped by 100% on the rear bar, / / Braided, the middle bar and the rear bar are image 3 organized by.

[0112] Front Bar: Tissue 01 / 21 / /

[0113] Middle bar: tissue 10 / 12 / 10 / 12 / 23 / 21 / 23 / 21 / /

[0114] Rear bar: tissue 10 / 12 / 10 / 12 / 23 / 21 / 23 / 21 / /

[0115] The knitted fabric was relaxed and refined using a continuous refining machine, and then pre-set at 190° C. for 1 minute, and nylon and cupro fibers were dyed using a flow dyeing machine. Fill softening agent after dyeing, under the condition of 170 ℃ and 1 minute, carry out finishing setting, have made warp knitted fabric.

[0116] The proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com